High-temperature fuel cell stack design

A high-temperature fuel cell and stack technology, used in fuel cells, heat preservation, circuits, etc., can solve the problems of temperature monitoring and control not reaching the ideal range, weak protection of battery packs, affecting energy conversion efficiency, etc. Energy conversion efficiency, improving assembly productivity, absorbing thermal expansion stress and strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

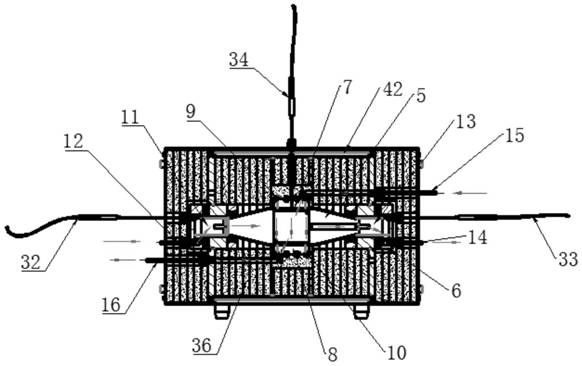

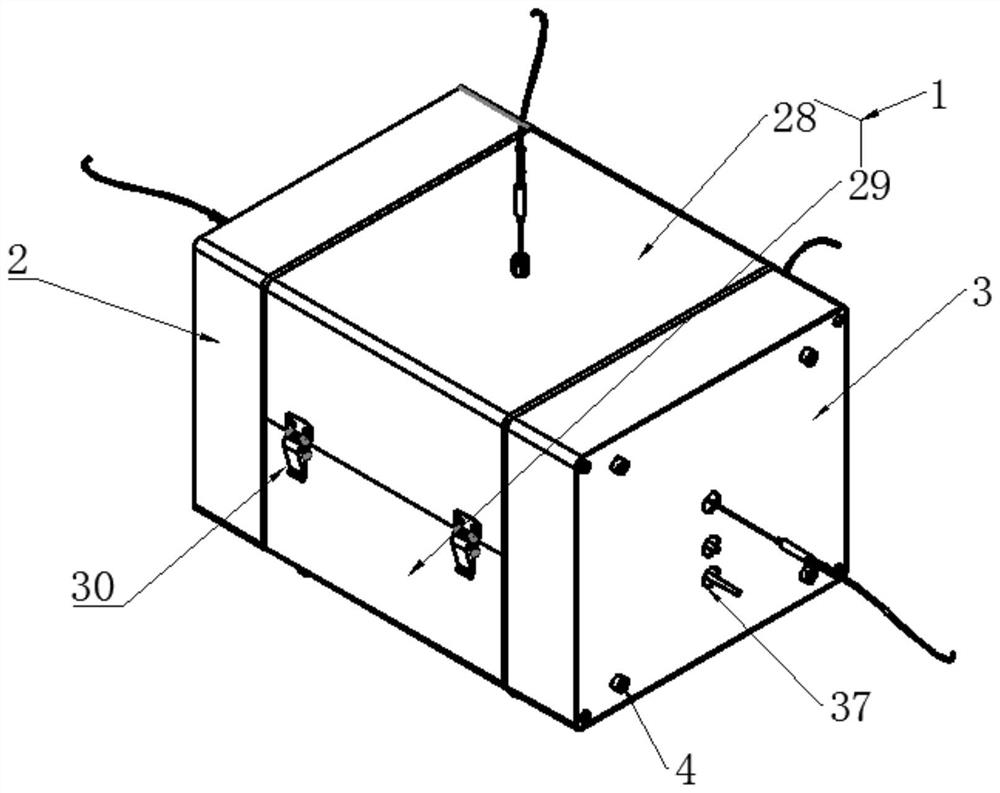

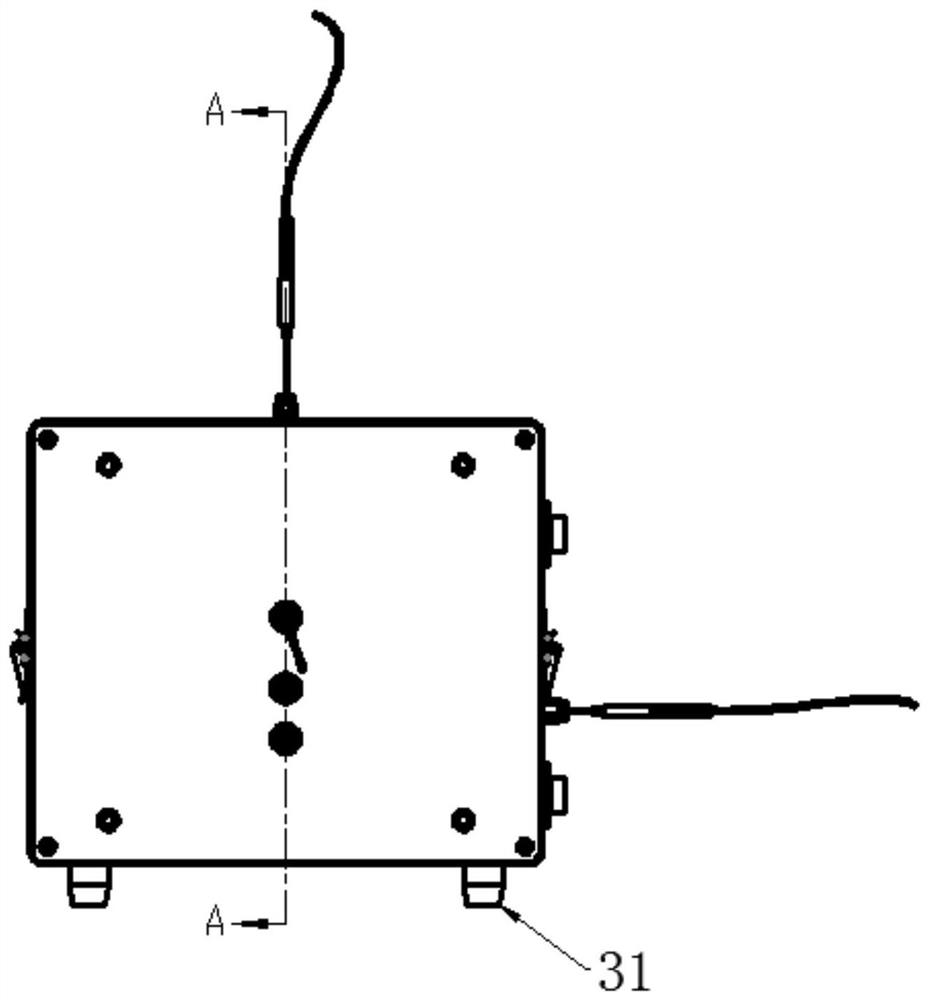

[0030] like Figure 1-4 As shown, the design of the high-temperature fuel cell stack according to the embodiment of the present invention includes a thermal insulation casing 1, and an air intake casing 2 is provided at one end of the thermal insulation casing 1, and the thermal insulation casing 1 is far away from the One end of the air inlet housing 2 is provided with an air outlet housing 3, and the air inlet housing 2, the air outlet housing 3 and the heat insulating housing 1 are fixedly connected by a plurality of connecting screws 4, respectively. A battery cell group 5 is arranged in the middle position inside the heat insulating shell 1 , and the battery core group 5 is connected with the heat insulating shell 1 through a limit fixing frame 6 . A thermal cavity 1 7 and a thermal cavity 2 8 are formed in the middle position between the thermal insulation shells 1. The top end inside the thermal cavity 1 7 is provided with a number of heat pipes 1 9, and the bottom end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com