A device for preparing film-coated proppant and its working method

A technology of proppant and film covering, applied in the field of hydraulic fracturing, which can solve the problems of insufficient strength of the surface covering film, limit the wide use of film covering proppant, and high price, achieve rapid heating and cooling, ensure safety and reliability, and guarantee The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

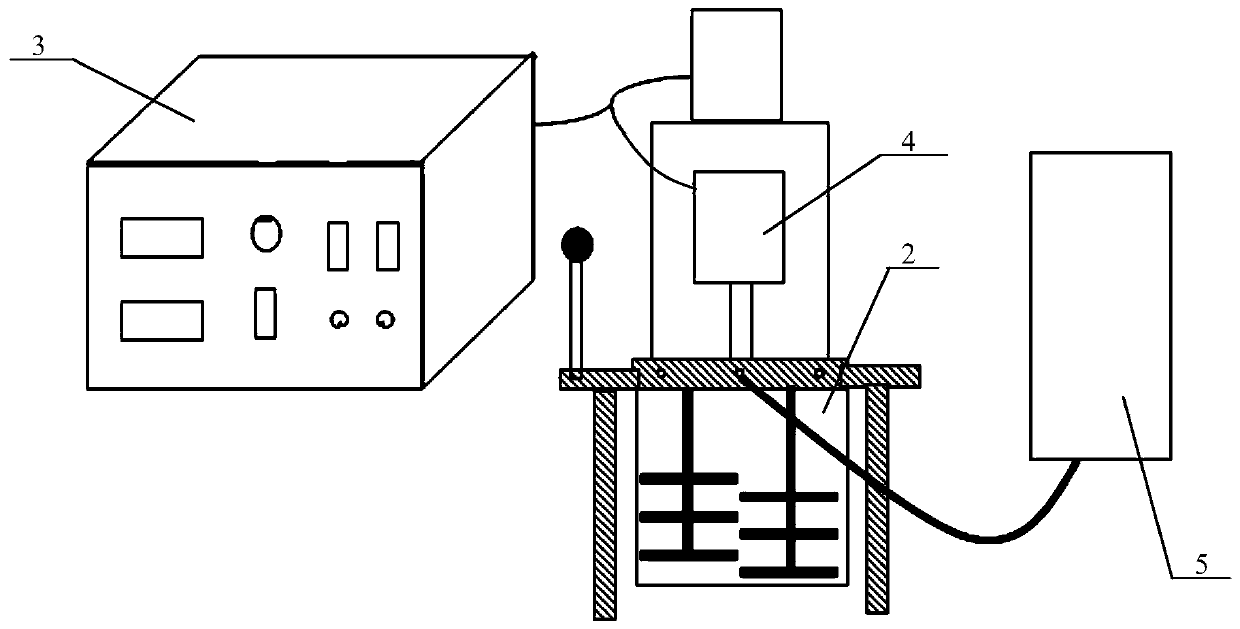

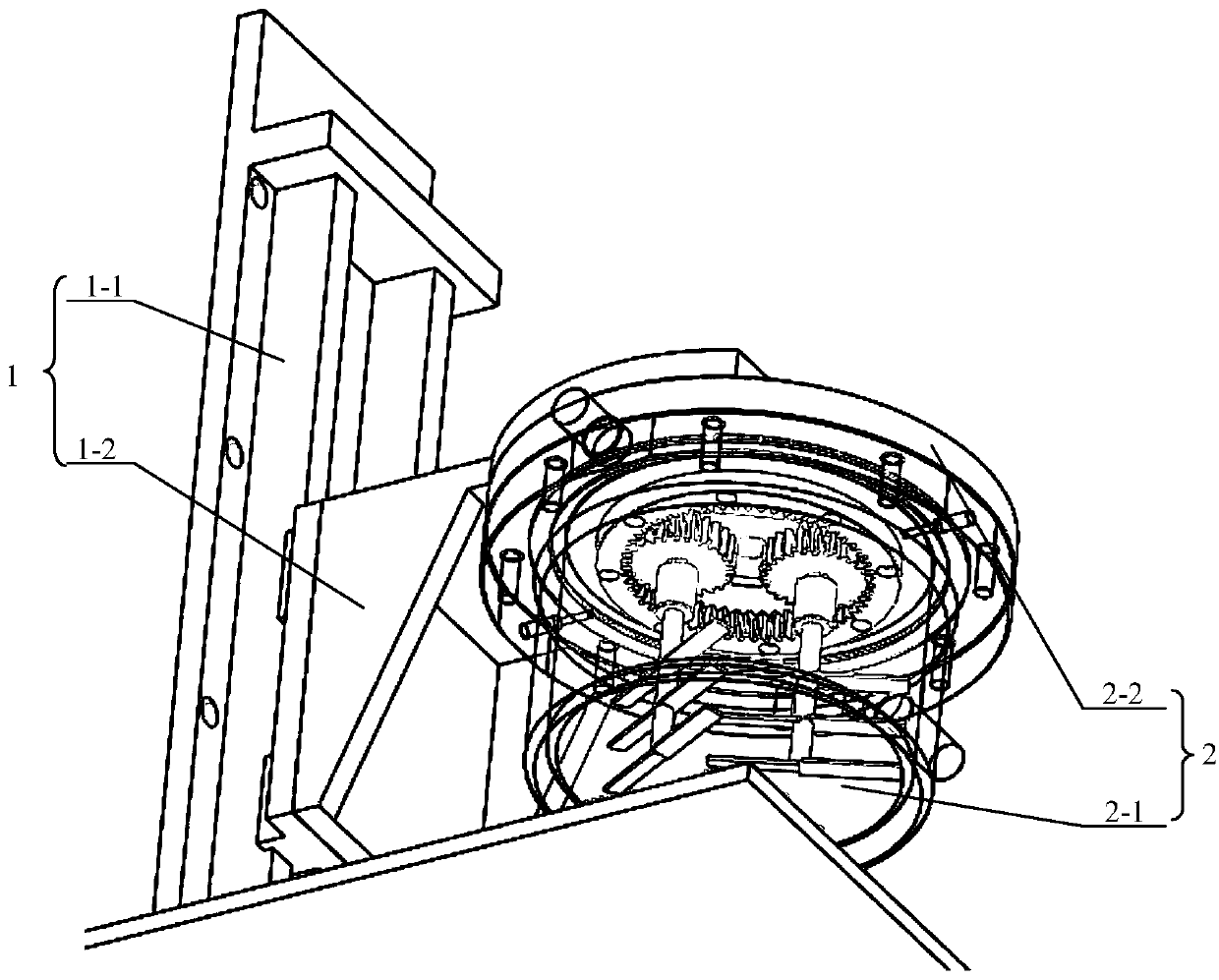

[0049] like Figure 1-5 As shown, a device for preparing film-coated proppants includes a lifting and sliding mechanism 1, a reaction kettle 2 and a control box 3. The lifting and sliding mechanism 1 includes a support frame 1-1 and a slider 1 that slides up and down along the support frame 1-1 -2, the reaction kettle 2 includes a kettle body 2-1 and a kettle cover 2-2, the kettle body 2-1 is connected to the support frame 1-1, and the kettle cover 2-2 is connected to the slider 1-2;

[0050] The kettle body 2-1 is equipped with a heating device and a stirring device, and the kettle body 2-1 is provided with an air inlet, an air outlet and a spraying port, and the spraying port is connected to a spray-type dosing system;

[0051] A controller is arranged in the control box 3, and the heating device, the stirring device and the spraying type dosing system are all connected to the controller.

Embodiment 2

[0053] A device for preparing a film-coated proppant, the structure of which is shown in Example 1, the difference is that the kettle body 2-1 includes an inner layer and an outer layer, and the heating device is a heating ring located between the inner layer and the outer layer, Under 220V, its heating power is 2700W, which is used for temperature control in the kettle body 2-1, and the heating coil is connected to the controller; the inner and outer layers are made of metal; there is also a temperature control device between the inner and outer layers. The sensor and the temperature controller are connected with the controller. The model of the temperature sensor can be flexibly selected according to the existing model. The working temperature in the kettle body is adjustable from 20 to 200 degrees Celsius, and the optimum temperature can be set to achieve the set optimum temperature. The controller can control the electric heating coil to stop heating and turn to the heat pr...

Embodiment 3

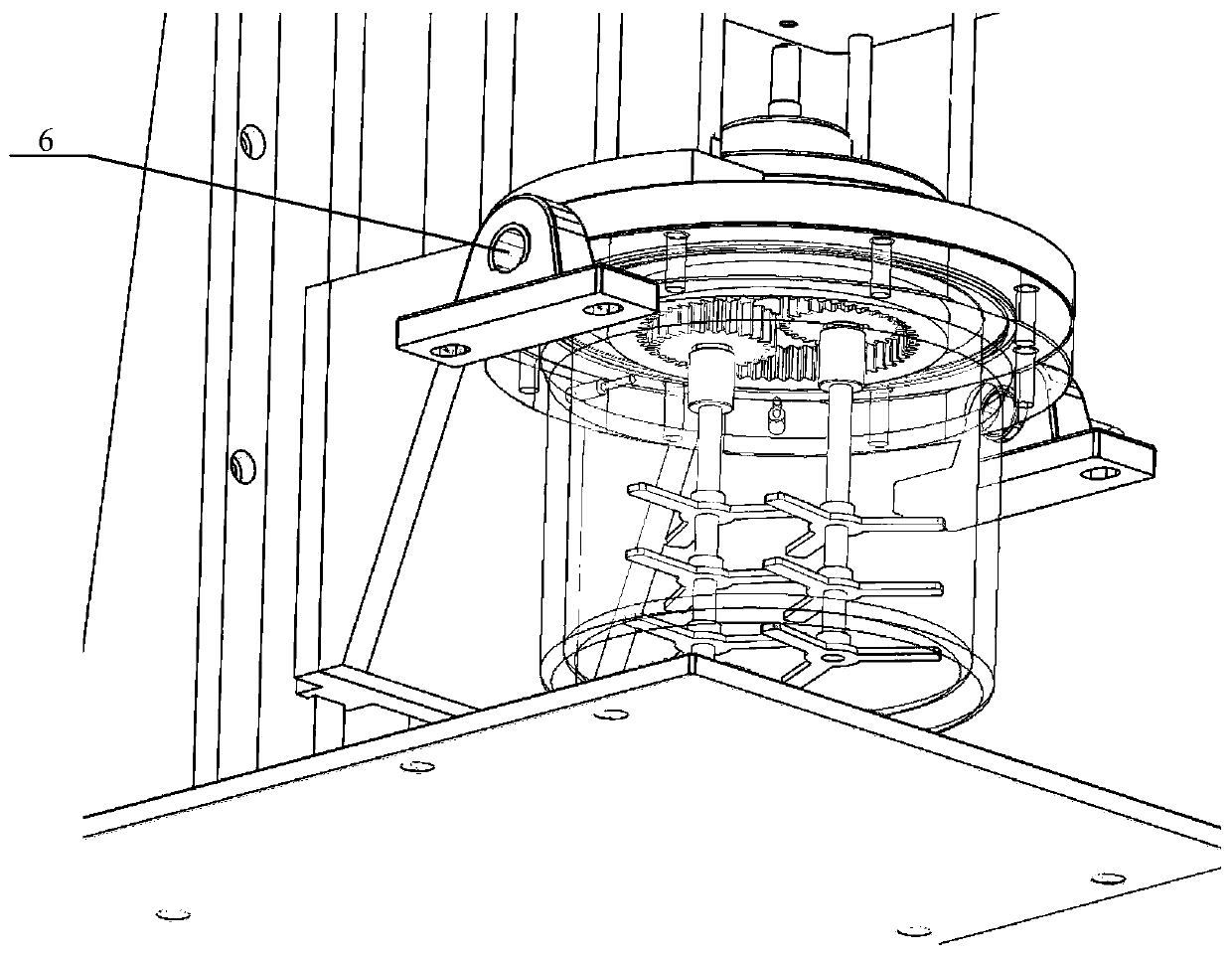

[0055] A device for preparing film-coated proppants, as shown in Example 2, the difference is that the stirring device includes a planet carrier, a sun gear, a first ring gear and a second ring gear, a first stirring shaft and a second stirring shaft , the planetary frame is set on the kettle cover 2-2, the first ring gear is connected to the first stirring shaft, the second ring gear is connected to the second stirring shaft, and multiple sets of stirring shafts are connected to the first stirring shaft and the second stirring shaft The paddle, the paddle of the stirring paddle is oblique to the stirring shaft, that is, it is inclined at a certain angle, such as figure 2 As shown, there are 2 blades;

[0056] The planet carrier is fixed, and a motor with adjustable speed is arranged on the sun gear or the ring gear. When the stirring device is working, the first stirring shaft and the second stirring shaft are respectively connected to the first ring gear and the second rin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com