Cold-rolled tin plate continuous annealing line temper mill roll shape configuration method and configuration structure

A configuration method and technology of annealing line, applied in the field of metallurgy, can solve the problems of reducing production time, shutdown replacement, uneven wear between rolls, etc., and achieve the goals of increasing average production speed, reducing rolling force pressure difference, and increasing service kilometers Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

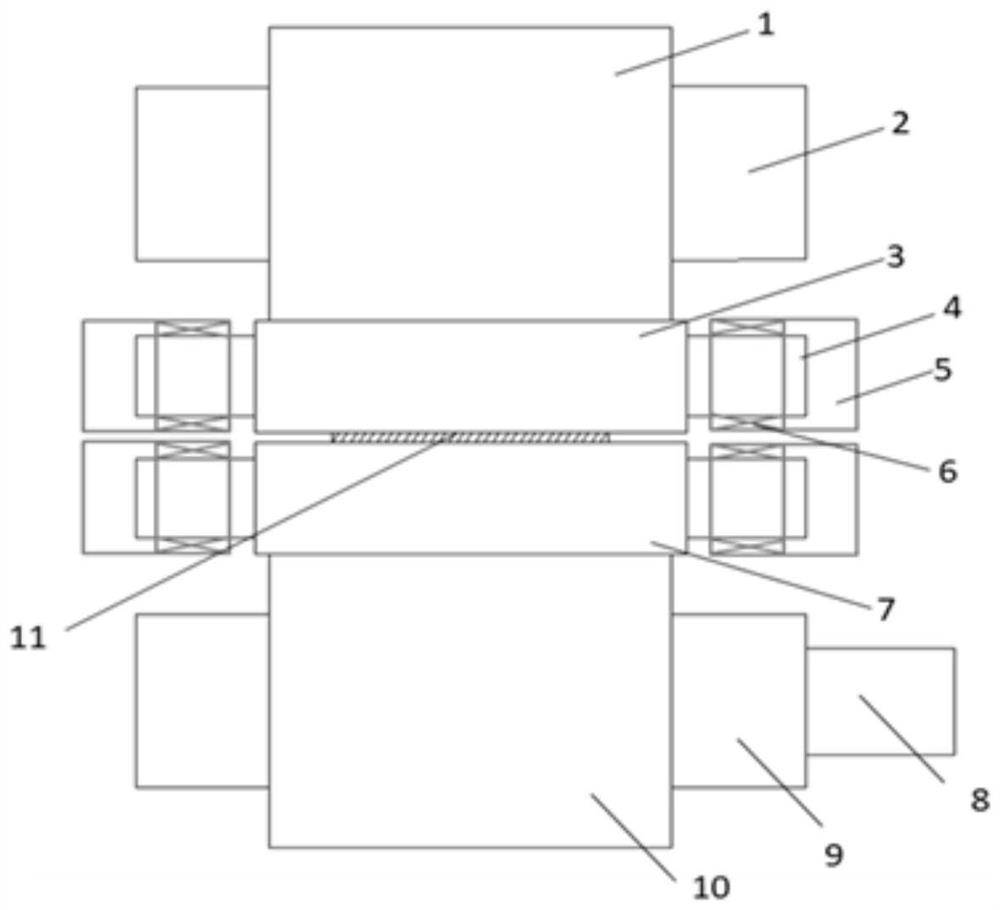

[0046] refer to Figure 1-12 , 13-07, TW044, TW073, and TW076 in the accompanying drawings of the specification are steel stamp numbers on the work rolls. The present invention provides a technical solution, a roll shape configuration method for a cold-rolled tin plate continuous annealing line tempering machine, including:

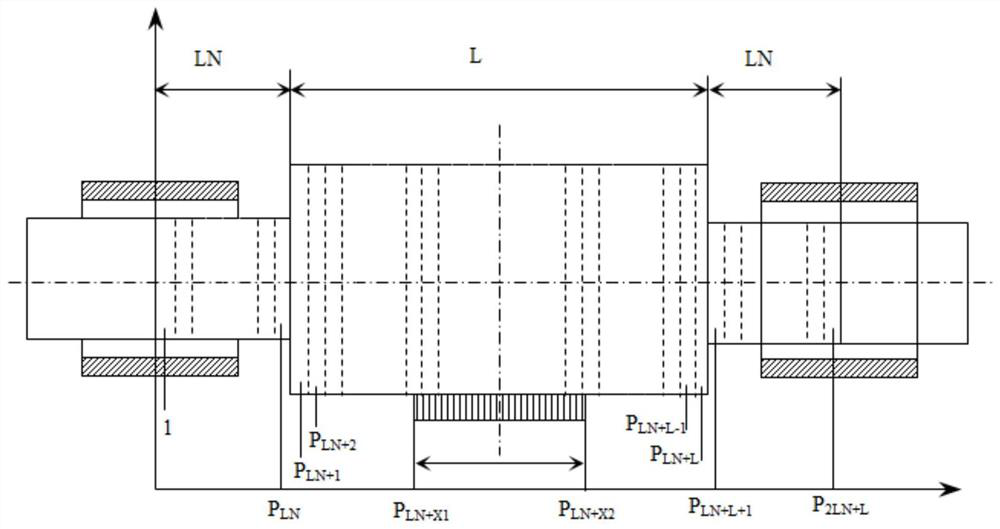

[0047] Step 1: Measure the temperature of each section of the work roll surface, regularly detect the hot and cold roll shapes of the off-line work rolls, combine the simulated annealing algorithm and the finite difference method, optimize and determine the parameters of the model with the measured data, and use the model Predict and calculate the hot roll shape of the work roll of the tempering machine of the tin plate continuous annealing unit, calculate the temperature change of each section of the roll surface at each stage of the work roll service period, predict the hot roll shape and the trend curve of the hot roll shape; the details are as follows:...

Embodiment 2

[0108] refer to Figure 1-12 13-07, TW044, TW073, and TW076 in the accompanying drawings of the specification are all steel stamp numbers on the work rolls. On the basis of Example 1, a roll shape configuration method for a cold-rolled tin plate continuous annealing line tempering machine includes:

[0109] Step 1: Use an infrared thermometer to continuously measure the temperature of each section of the work roll surface online, regularly use the Japanese Anritsu thermometer HA150K to measure the temperature of the work roll surface when the machine is off the machine, and use a saddle frame to detect the roll shape and shape of the off-line work roll. The cold roll shape, the difference between the hot roll shape and the cold roll shape is the measured hot roll shape, and the measurement results are shown in Figure 4 and Figure 5 . Using the combination of simulated annealing algorithm and finite difference method to model and predict the hot roll shape of the roll, opti...

Embodiment 3

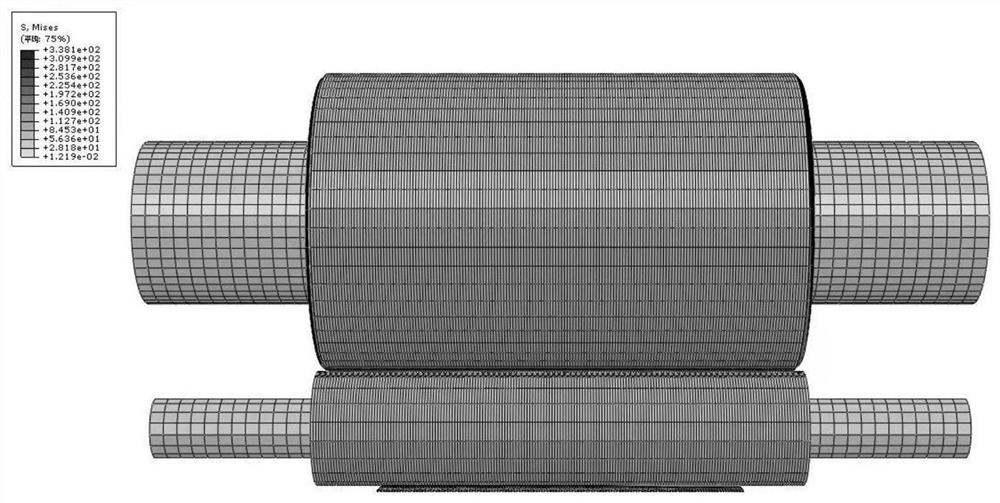

[0126] refer to Figure 1-12 , the present invention provides a technical solution, on the basis of Example 1, a roll shape configuration structure of a cold-rolled tin plate continuous annealing line tempering machine, the work roll adopts the roll shape curve of the TCR work roll, and the back-up roll adopts the SBR back-up roll Roller curve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com