Automobile lifting machine with detachable and replaceable supporting arms

A technology for lifts and automobiles, which is applied in lifting frames, lifting devices, etc., which can solve the problems of low safety in use of equipment and inconvenient disassembly and replacement of support arms, and achieve the effect of improving convenience and safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

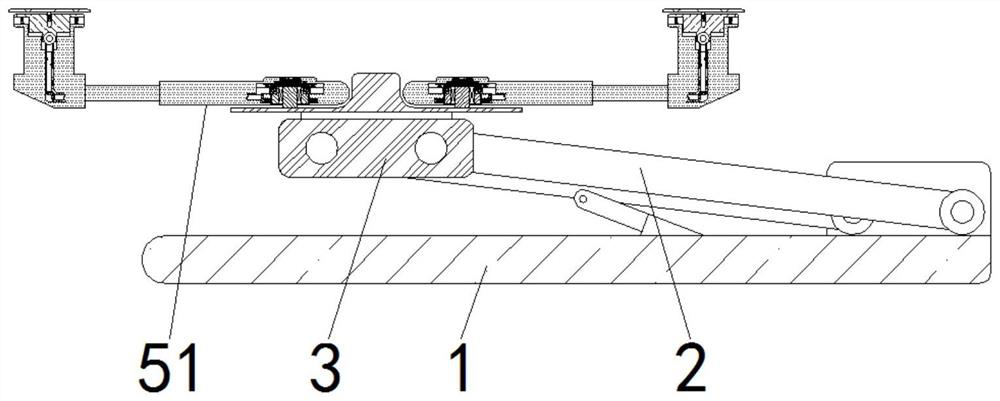

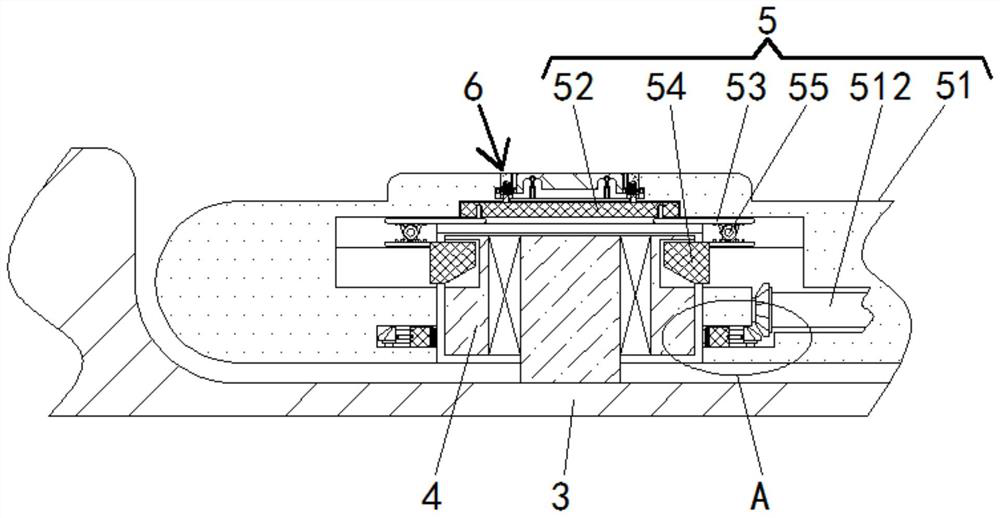

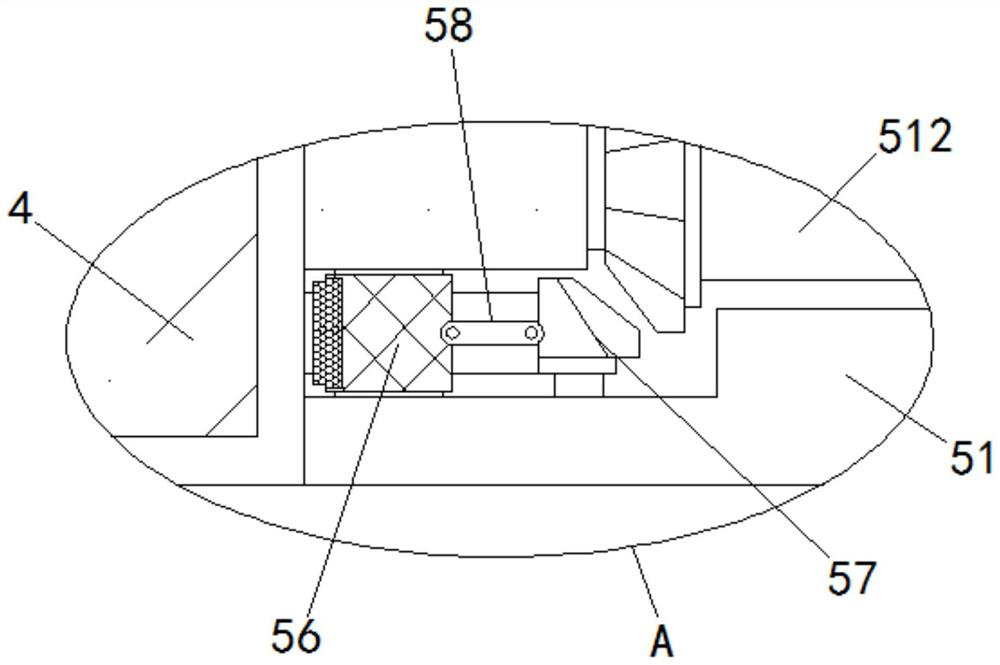

[0025] See Figure 1 - Figure 5 A car lift, including the base 1, and the top of the base 1, and the top activity of the double strut 2 is connected to the left and right sides of the double strip bit 3. All rotation is rotated, and the support mechanism 5 is attached to the bearing 4, the support mechanism 5 includes a telescopic arm 51, and the top rotation of the inner cavity bearing 4 of the telescopic arm 51 is rotated to be connected to the adjusting disk 52, and the bottom of the adjustment disk 52 is left. The curved groove corresponding to the rack 53 is opened, and the upper end of the rack 53 has a guide to extend to the curved groove, thereby facilitating the adjustment of the rack 53 from the sides of the rack 53, telescopic arm. The rack 53 is attached to the bottom left and right sides of the bottom of 51, and the left and right sides of the inner cavity bearing 4 of the telescopic arm 51 are slidably connected to the bipper block 54, and the cartridge block 54 is op...

Embodiment 2

[0027] See figure 2 and Image 6 A car lift, a trunk detachable car, further comprising a regulating mechanism 6, and the control mechanism 6 is actively coupled to the top of the telescopic arm 51, and the regulatory mechanism 6 includes an arc plate 61, an arc plate 61 and a press plate 63 in a telescopic arm. 51 The surface is embedded in the surface of the surface, thereby effectively avoiding the relevant mechanism for adjustment, and the sidewall of the arc plate 61 is opened with a loop slot corresponding to the positioning pin 66, thereby facilitating the use of the positioning pin 66 against the arc plate 61. The telescopic arm 51 performs an internal bifurcated limit, and the arc plate 61 and the adjusting disk 52 are fixed to the contact spring 62, and the top wall cavity of the telescopic arm 51 slides the pressing plate 63, press the plate 63 and the telescopic arm 51. The inner wall is fixedly connected to the elastic column 64, and the upper and left sides of the pre...

Embodiment 3

[0029] See Figure 1 - Figure 6A car lift, including the base 1, and the top of the base 1, and the top activity of the double strut 2 is connected to the left and right sides of the double strip bit 3. All rotation is rotated, and the support mechanism 5 is attached to the bearing 4, the support mechanism 5 includes a telescopic arm 51, and the top rotation of the inner cavity bearing 4 of the telescopic arm 51 is rotated to be connected to the adjusting disk 52, and the bottom of the adjustment disk 52 is left. The curved groove corresponding to the rack 53 is opened, and the upper end of the rack 53 has a guide to extend to the curved groove, thereby facilitating the adjustment of the rack 53 from the sides of the rack 53, telescopic arm. The rack 53 is attached to the bottom left and right sides of the bottom of 51, and the left and right sides of the inner cavity bearing 4 of the telescopic arm 51 are slidably connected to the bipper block 54, and the cartridge block 54 is ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com