LED packaging adhesive film, application of LED packaging adhesive film and LED packaging structure

A technology of LED encapsulation and encapsulation film, which is applied in the direction of film/sheet adhesives, adhesives, films/sheets without carriers, etc. The effect of junction stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

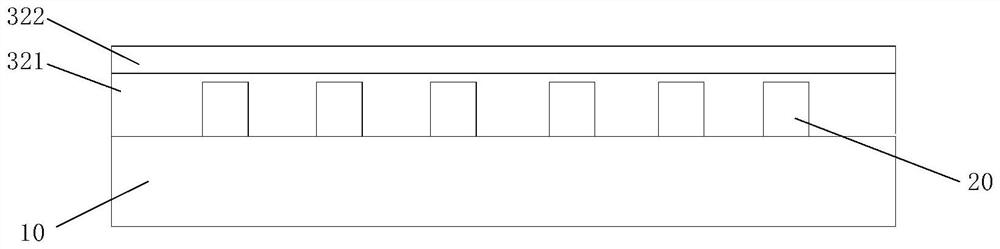

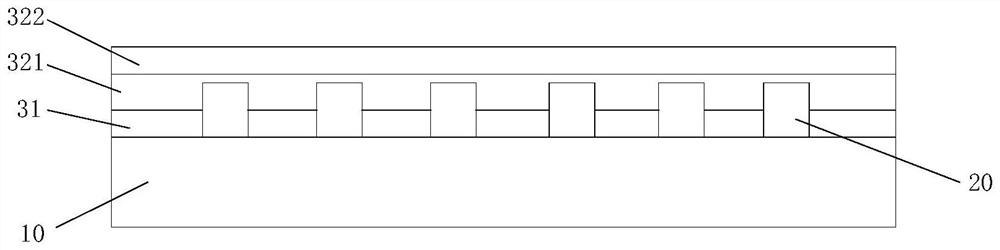

Image

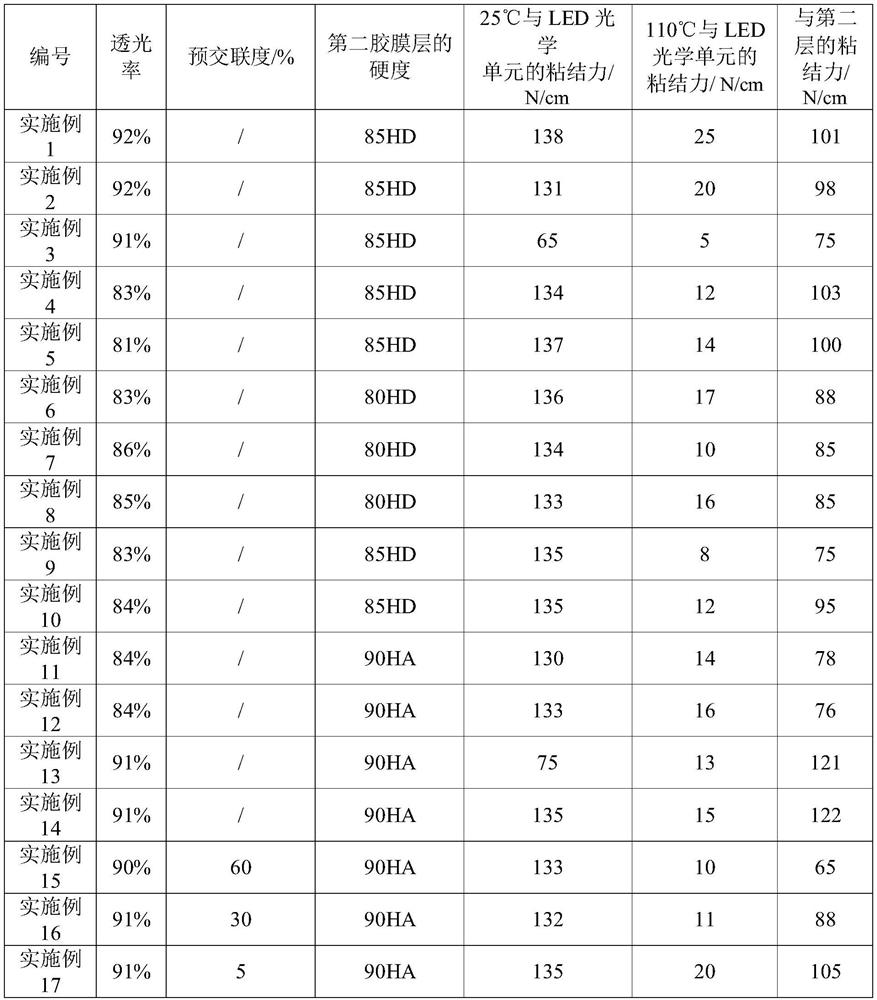

Examples

Embodiment 1

[0048] The LED packaging adhesive film double-layer film of Example 1 includes a first adhesive film layer and a second adhesive film layer. The first adhesive film layer is a silane-modified ethylene-butene copolymer (Dow Chemical) with a melting index of 8 g / 10min and a thickness of 200 μm. The second adhesive film layer is a PET film (DuPont) with a thickness of 10 μm.

Embodiment 2

[0050] The LED packaging adhesive film double-layer film of Example 2 includes a first adhesive film layer and a second adhesive film layer. The first adhesive film layer comprises 90wt% of silane-modified ethylene-butene copolymer with a melt index of 5g / 10min and 10wt% of an ethylene-vinyl acetate copolymer with a melt index of 30g / 10min, and has a thickness of 50 μm. The second adhesive film layer is a PET film (DuPont) with a thickness of 50 μm.

Embodiment 3

[0052] The LED packaging adhesive film double-layer film of Example 3 includes a first adhesive film layer and a second adhesive film layer. Wherein the first adhesive film layer comprises 50wt% of a silane-modified ethylene-butene copolymer (Dow Chemical) with a melt index of 30g / 10min and 50wt% of an ethylene-vinyl acetate copolymer with a melt index of 15g / 10min, The thickness is 200 μm. The second adhesive film layer is a PET film (DuPont) with a thickness of 300 μm and a random embossing of 10 μm deep on the surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com