Frame type monorail track for mountain light rail

A frame-type and rail-based technology, which is applied to rails, roads, buildings, etc., can solve the problems of vehicle overturning, high overall cost, and heavy weight, and achieve the effects of reduced volume and weight, reduced construction difficulty, and reduced overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

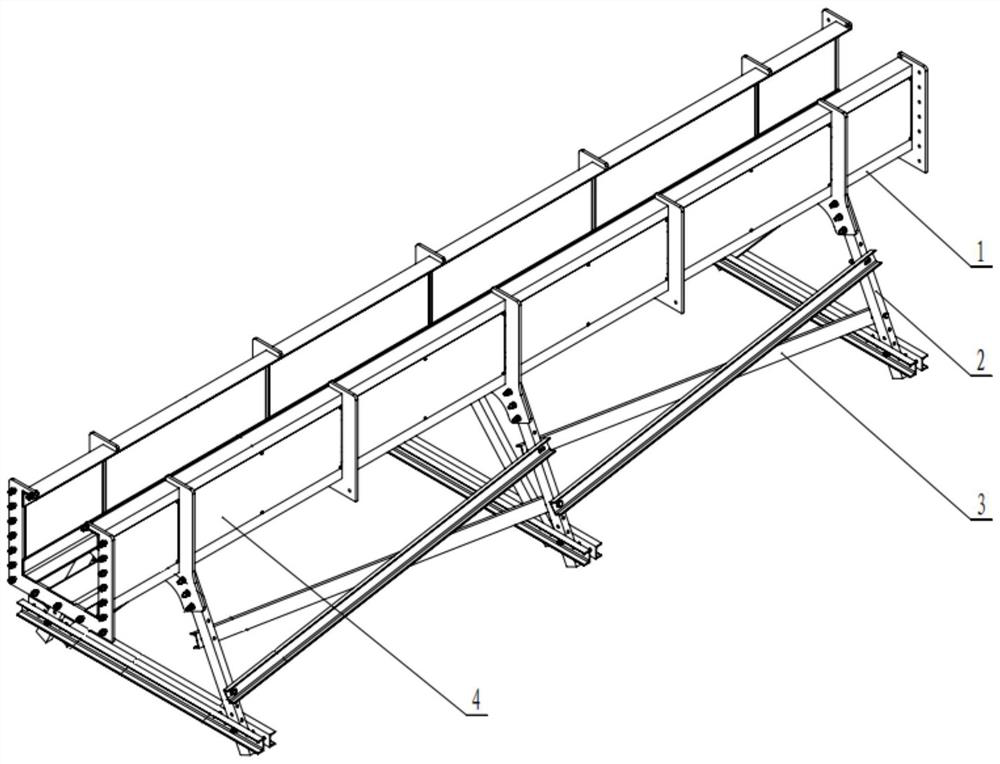

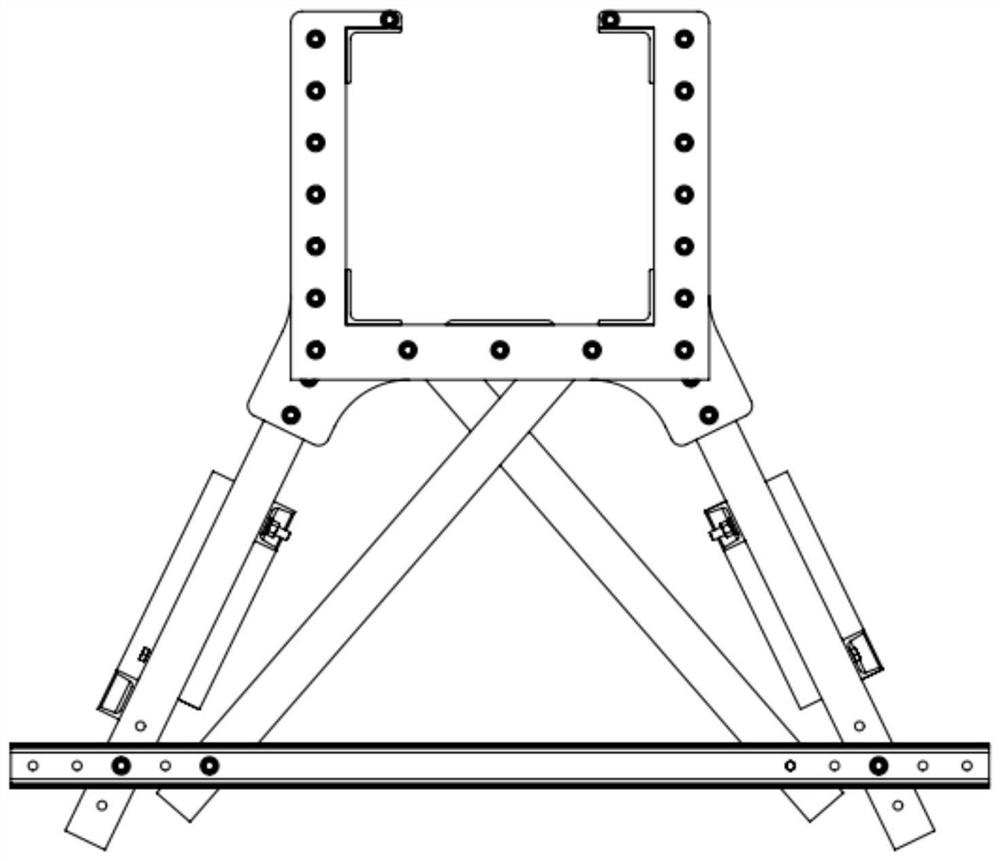

[0046] attached Figure 7 , attached Figure 8 An example of mountain light rail track application in mountain light rail transportation.

[0047] The two built-in bogies of the rail vehicle are shown as 100 in the figure.

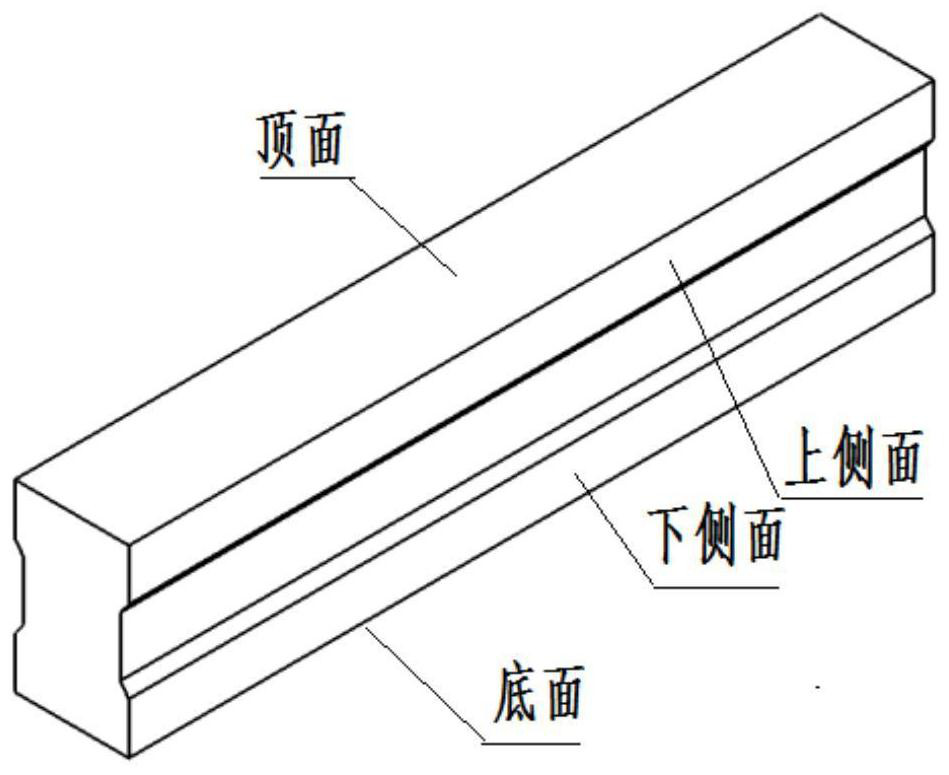

[0048] The running wheels 101, stabilizing wheels 102, guide wheels 103 and guide wheels 104 of the bogie are all fixed on the bogie frame of the vehicle. The running wheels 101 are in contact with the upper top surface of the track bottom surface 15, and when the running wheels 101 rotate, they receive friction from the track bottom surface 15, so that the rail vehicle moves forward or backward. The stabilizing wheel 102 is in contact with the inner horizontal plane of the track beam 11, when the rail vehicle is subject to side wind force (such as attached Figure 8 In the right direction) or the centrifugal force generated by turning, the rail vehicle will have a right side (such as the attached Figure 8 If there is a tendency to swing to the right)...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap