Anti-loosening riveting bolt and corresponding riveting tool

A technology for riveting bolts and riveting tools, applied in the directions of bolts, screws, nuts, etc., can solve the problems of weakening the tightness of tightening, hidden dangers, reduction of pre-tightening force, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

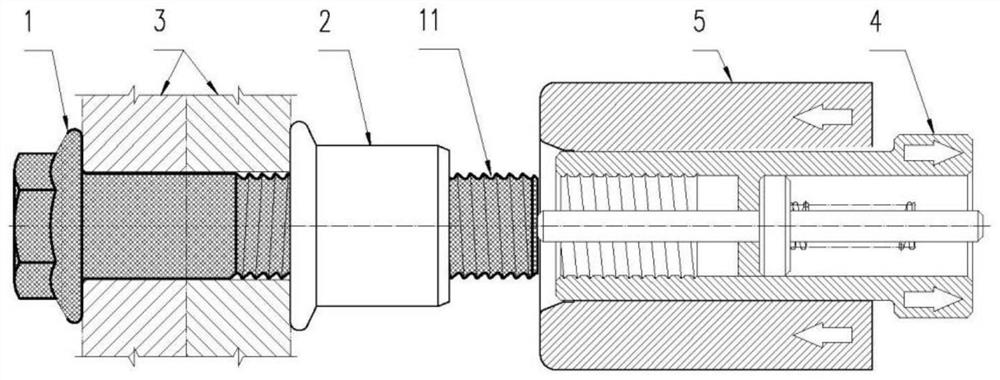

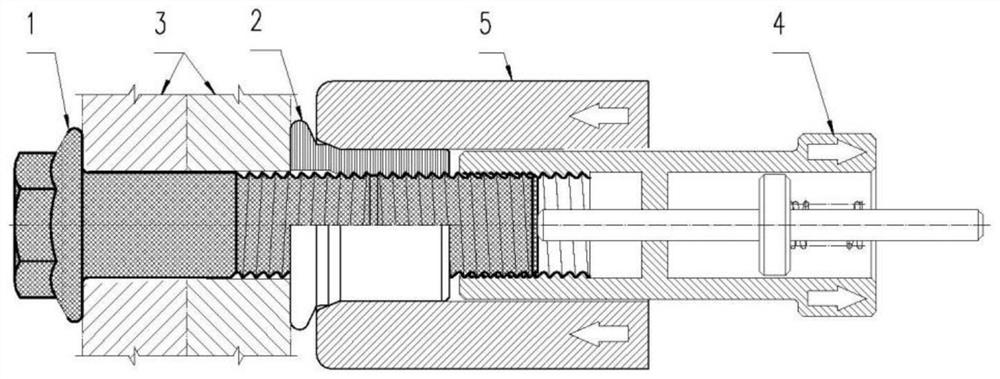

[0046] The structure of the present invention will be further described in detail below in conjunction with the accompanying drawings.

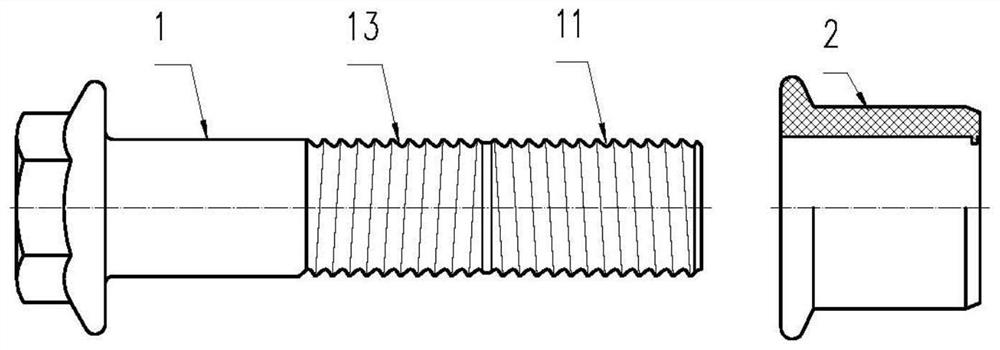

[0047] An anti-loosening riveted bolt,

[0048] Two or more workpieces 3 for fastening connection are provided with a through hole, the bolt penetrates through the through hole from one side, and the fastening surface of the bolt head is against the outer wall of one side of the through hole, which is characterized in that:

[0049] The bolt shaft 1 of the bolt protrudes from the outer wall on the other side, and the diameter of the entire length of the bolt shaft 1 is the same;

[0050] 2 sets of lock rings including flanges are placed on the protruding end of the bolt rod 1, and the flange surface is close to the outer wall of the other side, and is squeezed and deformed by the riveting tool, formed and engaged on the thread of the screw rod 1, and pressed tightly on the thread of the screw rod 1. the other side of the outer wall;

[0051...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com