Electrolyte flame-retardant additive material with triphenyl phosphate and polydopamine microcapsule structure and synthesis method of electrolyte flame-retardant additive material

A technology of dopamine microcapsules and triphenyl phosphate is applied in the field of battery flame retardant materials, which can solve problems such as battery thermal runaway, and achieve the effect of improving the application effect and expanding the application scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

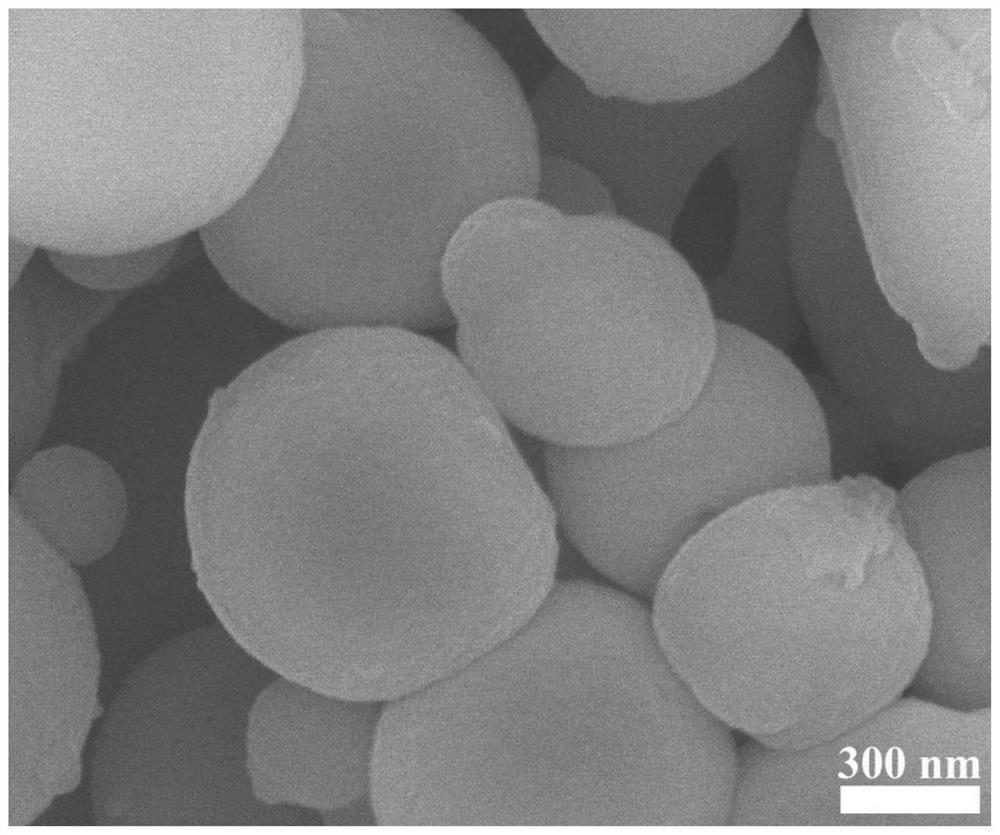

[0027] An electrolyte flame retardant additive material with a triphenyl phosphate@polydopamine microcapsule structure, including the following components: 0.5 g of triphenyl phosphate, 20 mL of absolute ethanol, 500 mL of deionized water, and 0.605 g of trishydroxymethylaminomethane , dopamine hydrochloride 0.5g;

[0028] Its preparation method comprises the following steps:

[0029] Weigh 0.5g of triphenyl phosphate and dissolve in 20mL of absolute ethanol, and disperse evenly by ultrasonication for 10 minutes;

[0030] Then, take another 1L large beaker and add 500mL of deionized water, then weigh 0.605g of tris to dissolve in deionized water, stir mechanically for 10 minutes to disperse evenly;

[0031] Then add the ethanol solution dropwise into deionized water (while dripping with mechanical stirring), after the dispersion is uniform, weigh 0.5g of dopamine hydrochloride and add it to the above mixed solution, and mechanically stir for 24 hours;

[0032] Finally, the m...

Embodiment 2

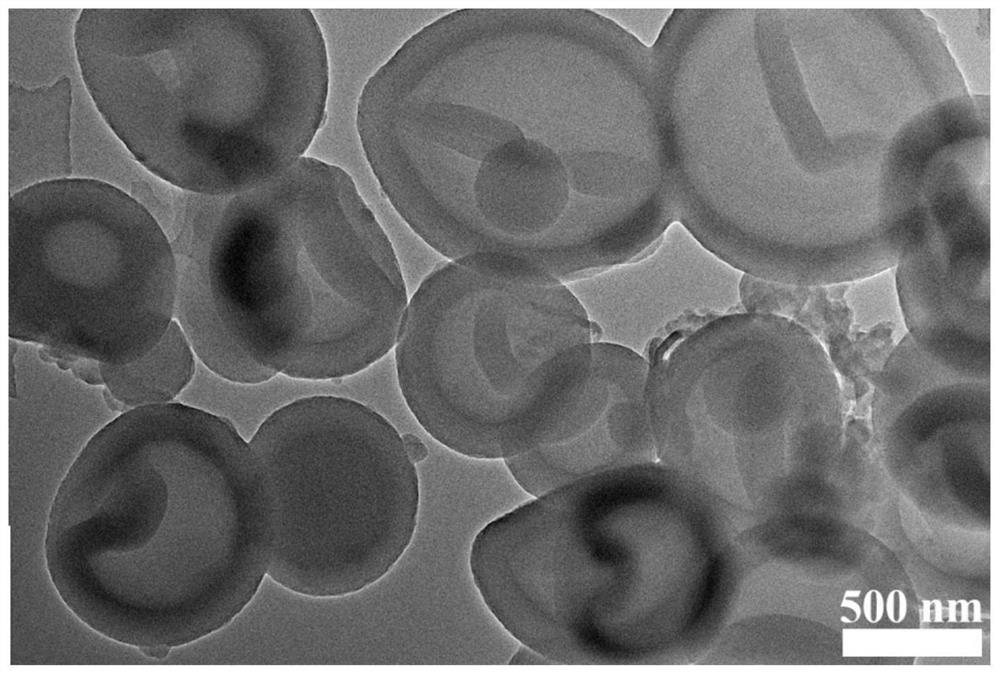

[0035] An electrolyte flame retardant additive material with a triphenyl phosphate@polydopamine microcapsule structure, including the following components: 0.5 g of triphenyl phosphate, 20 mL of absolute ethanol, 500 mL of deionized water, and 0.605 g of trishydroxymethylaminomethane , dopamine hydrochloride 0.5g;

[0036] Its preparation method comprises the following steps:

[0037] Weigh 0.5g of triphenyl phosphate and dissolve in 20mL of absolute ethanol, and disperse evenly by ultrasonication for 10 minutes;

[0038] Then, take another 1L large beaker and add 500mL of deionized water, then weigh 0.605g of tris to dissolve in deionized water, stir mechanically for 10 minutes to disperse evenly;

[0039] Then add the ethanol solution dropwise into deionized water (while dripping with mechanical stirring), after the dispersion is uniform, weigh 0.5g of dopamine hydrochloride and add it to the above mixed solution, and mechanically stir for 24 hours;

[0040] Finally, the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com