Welding equipment and welding method for bottom frame of screw machine

A welding equipment, screw machine technology, applied in welding equipment, welding equipment, auxiliary welding equipment and other directions, can solve the problems of the large number of sheet metal parts of the chassis, complicated connections, deformation of the chassis structure, etc., to improve the welding quality and Welding efficiency, accurate position effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

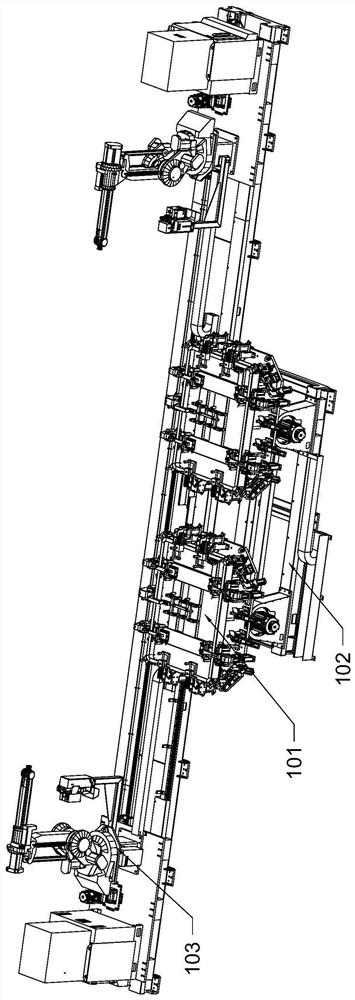

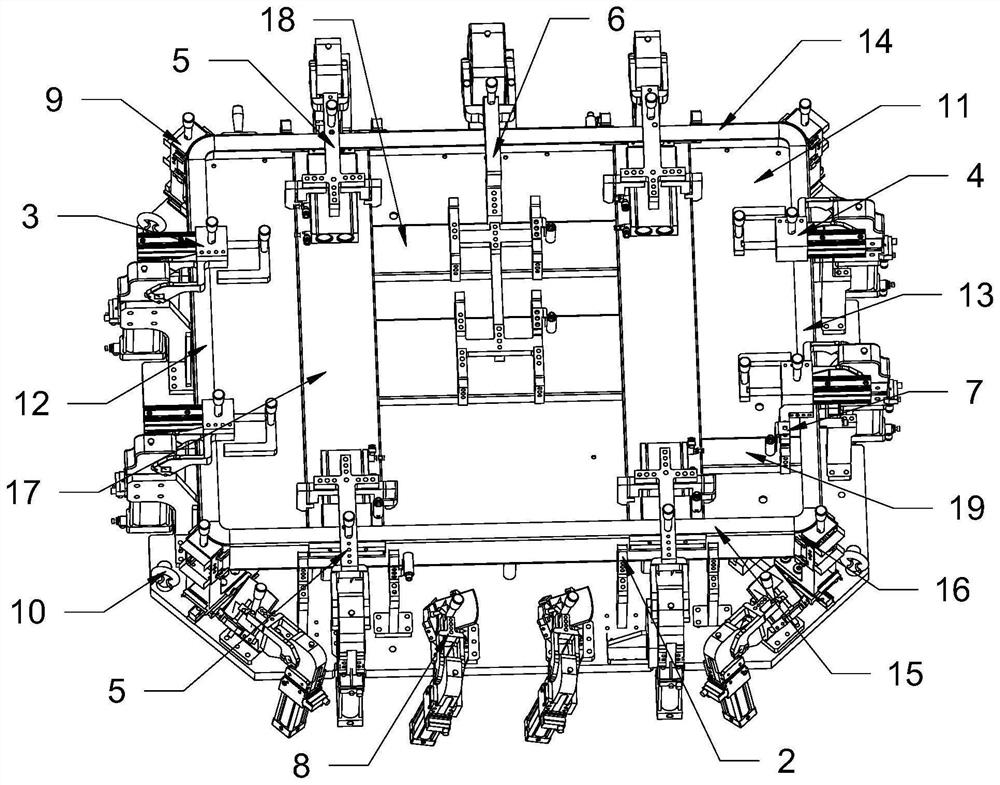

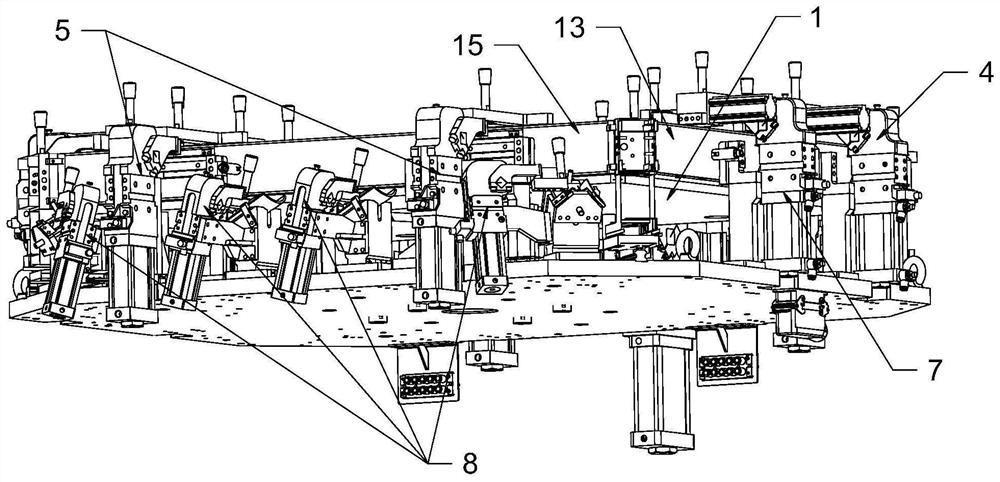

[0035] Such as figure 1 As shown, a welding equipment for the chassis of a screw machine, the equipment includes a tooling fixture 101, a three-axis positioner 102 and a welding robot device 103, the tooling fixture 101 is arranged on the output end of the three-axis positioner 102, and the three-axis One side of the positioner 102 is provided with a welding robot device 103 . The tooling fixture 101 is used for positioning and pressing the chassis workpiece to be welded. The three-axis positioner 102 is used to change the position of the fixture 101 . The welding robot device 103 is used to weld the chassis workpiece. The output end of the three-axis positioner 102 can at least move left and right, flip left and right, and turn in the horizontal plane.

[0036] Preferably, the welding robot device 103 includes a welding robot, a traveling slide rail, a traveling motor, a gear and a rack. There are two welding robots, and the bottoms of the two welding robots are all arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com