Tobacco logistics line empty tray warehousing detection system

A detection system and logistics line technology, applied in conveyors, storage devices, transportation and packaging, etc., can solve the problems of unable to clean up residual foreign objects in real time, unable to detect whether there are foreign objects in empty pallets, etc., so as to improve the efficiency of troubleshooting and improve equipment. and product safety, the effect of warehousing process safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution of the present application will be described in detail below in conjunction with the accompanying drawings. The following embodiments are only exemplary, and can only be used to explain and illustrate the technical solution of the present application, and cannot be interpreted as limitations on the technical solution of the present application.

[0033] In the technical solution of the present application, the "left", "right", "first", "second", etc. mentioned are all used to describe the technical solution of the present application, and are not used to determine the number or position limits.

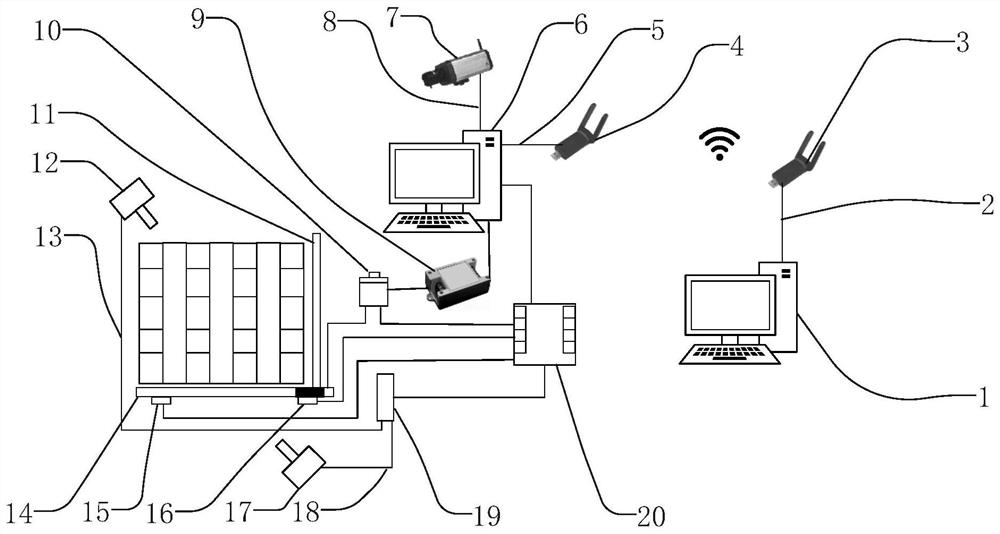

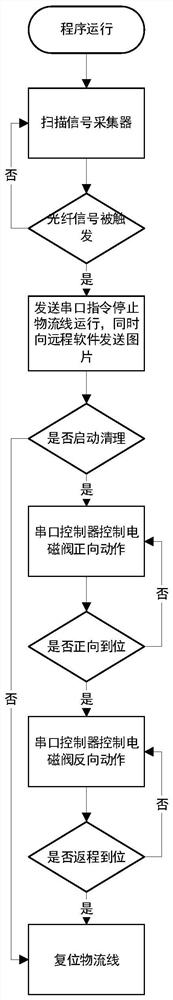

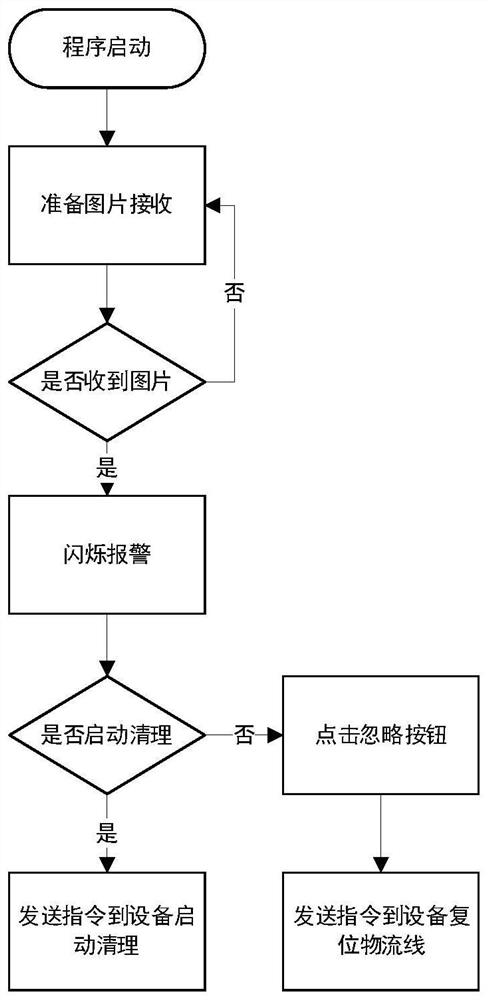

[0034] Such as figure 1 As shown, the application provides a tobacco logistics line empty pallet storage detection system, including a local industrial computer 6, a local control program is installed on the local industrial computer, a remote industrial computer 1, a remote control program is installed on the remote industrial computer . The local indu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com