Downhole instrument blade connecting structure

A technology for connecting structures and downhole instruments, applied in drilling equipment, earth-moving drilling, drill pipes, etc., can solve the problems of inconvenient product design and instrument maintenance, complex structure, etc., and achieve convenient design and development, simple and effective connection structure, and occupation small space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

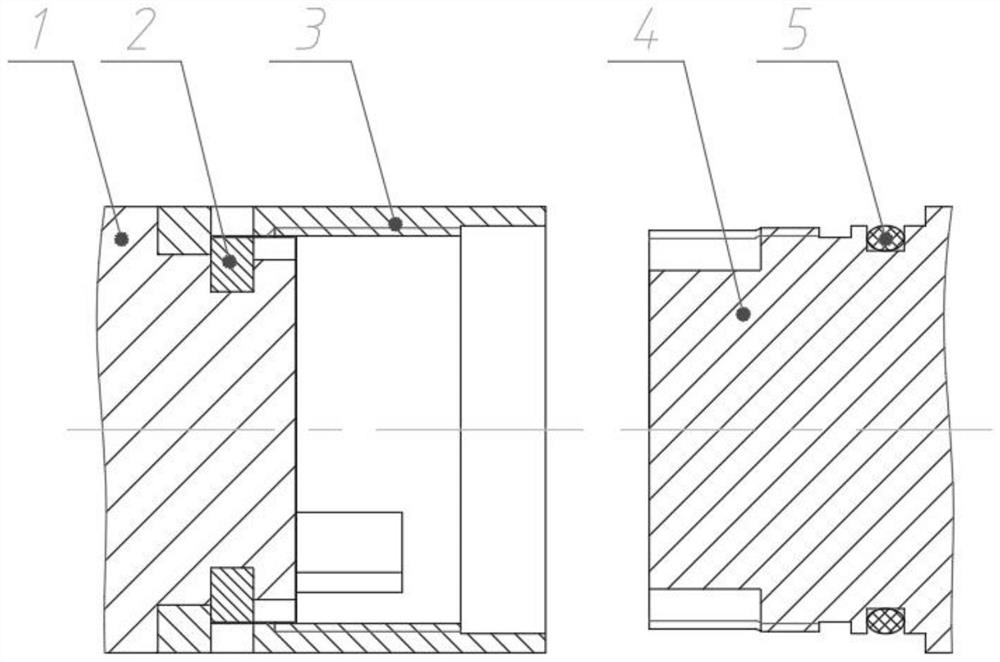

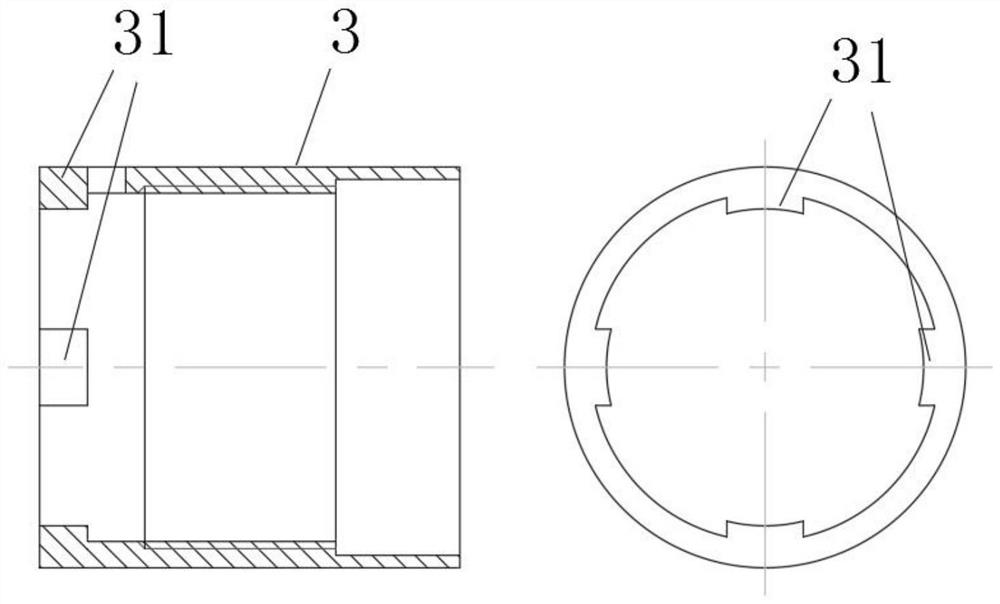

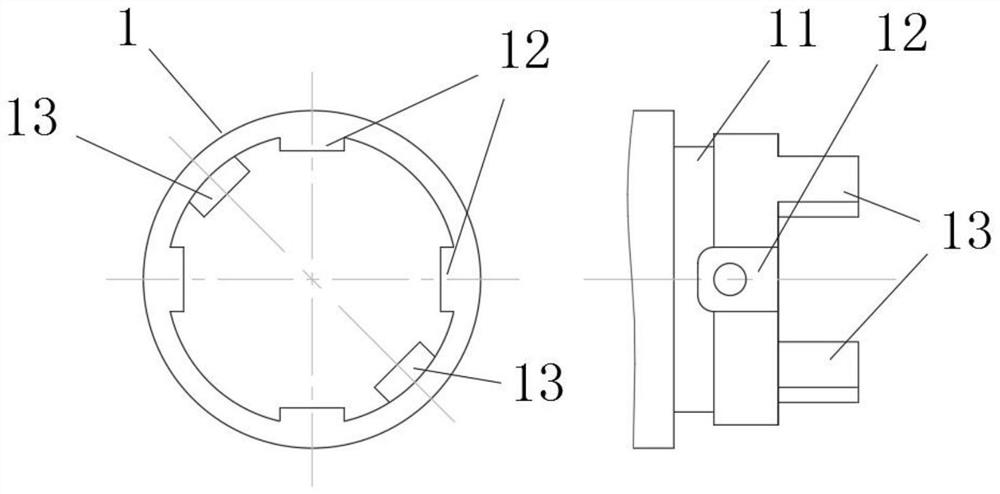

[0015] refer to Figure 1 to Figure 4 , this embodiment provides a free-cutting connection structure for downhole instruments, including a component 1, a component 2 4 and a connecting nut 3 for connecting and fixing them. One end of the connecting nut 3 is distributed with four bosses 31 along the circumferential direction. , the diameter of the connection end of component one 1 is less than or equal to the inner diameter of the connection nut 3, and the outer wall of the connection end of component one 1 is provided with step grooves 11 for clamping the boss 31 along the circumferential direction, and the outer wall of the connection end of component one 1 corresponds to four The boss 31 is also provided with a mounting groove 12 connected to the step groove 11, and one end of the connecting nut 3 is sleeved in the mounting groove 12 of the component one 1 through the boss 31, and by sequentially screwing the connecting nut 3 and the component one The positioning pin 2 of 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com