Strip type working face filling mining method

A mining method and working face technology, which is applied in the direction of filling, ground mining, mining equipment, etc., can solve the problems of gas accumulation, high operation requirements, and insufficient air volume, and achieve the prevention of gas and heat accumulation, high safety, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

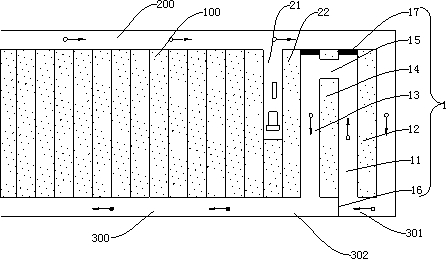

[0043] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

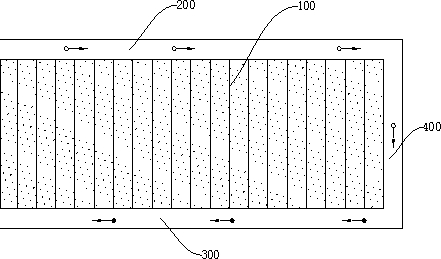

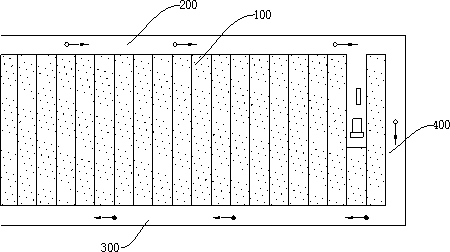

[0044] Refer below Figure 1 to Figure 6 The zigzag ventilated strip working face filling mining method according to the embodiment of the present invention is described.

[0045] The strip-type working face filling and mining method with zigzag ventilation according to the embodiment of the present invention comprises the following steps:

[0046] 1) Digging in and out of the transportation chute 200, the return air chute 300 and the cutout 400 to form the working face 100 to be mined and a U-shaped ventilation channel. The working face 100 to be mined includes N mining areas, and N is an integer greater than or equal to 2 ;

[0047] 2) Excavate the first min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com