Anti-backflow self-suction water pump

A self-priming water pump and anti-backflow technology, applied in the field of water pumps, can solve the problems of inability to extract accumulated water, poor self-priming capacity of self-priming pumps, and increase labor pressure of people, so as to improve work efficiency and self-priming capacity, and increase production. The ability of negative pressure, the effect of improving the pumping capacity of the pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with embodiment:

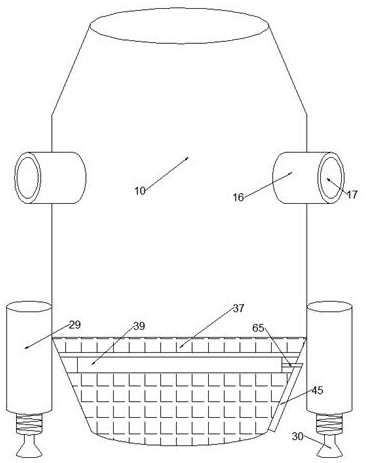

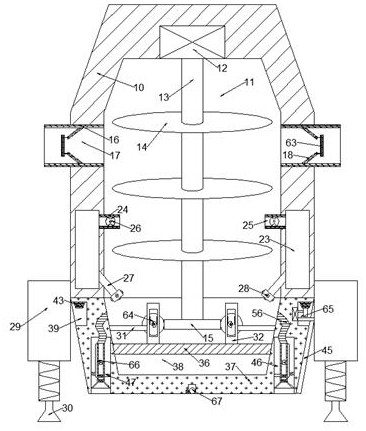

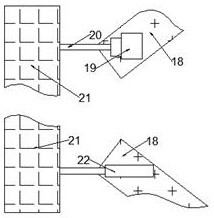

[0038] Refer to attached Figure 1-Figure 7 The shown anti-backflow self-priming water pump includes a casing 10, the casing 10 is provided with a first cavity 11 with the opening facing downward, and a filter casing 37 is fixed on the bottom wall of the casing 10, The filter housing 37 is provided with a second cavity 38 communicating with the first cavity 11, the filter housing 37 is provided with holes to provide water inflow, and the top wall of the first cavity 11 A first motor 12 is fixed, and the first motor 12 is installed with a first rotating shaft 13 extending into the second cavity 38. On the first rotating shaft 13 in the first cavity 11 Three impellers 14 are fixed at equal intervals. The left and right side walls of the first cavity 11 are connected with outlet pipes 16 with symmetrical left and right positions. Equipped with an anti-backflow device 63 to prevent bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com