Firmly-connected hose compensator

A compensator and hose technology, applied in the direction of hose connection devices, pipes/pipe joints/pipes, mechanical equipment, etc. And the effect of firm tightening, increasing friction, and saving tightening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

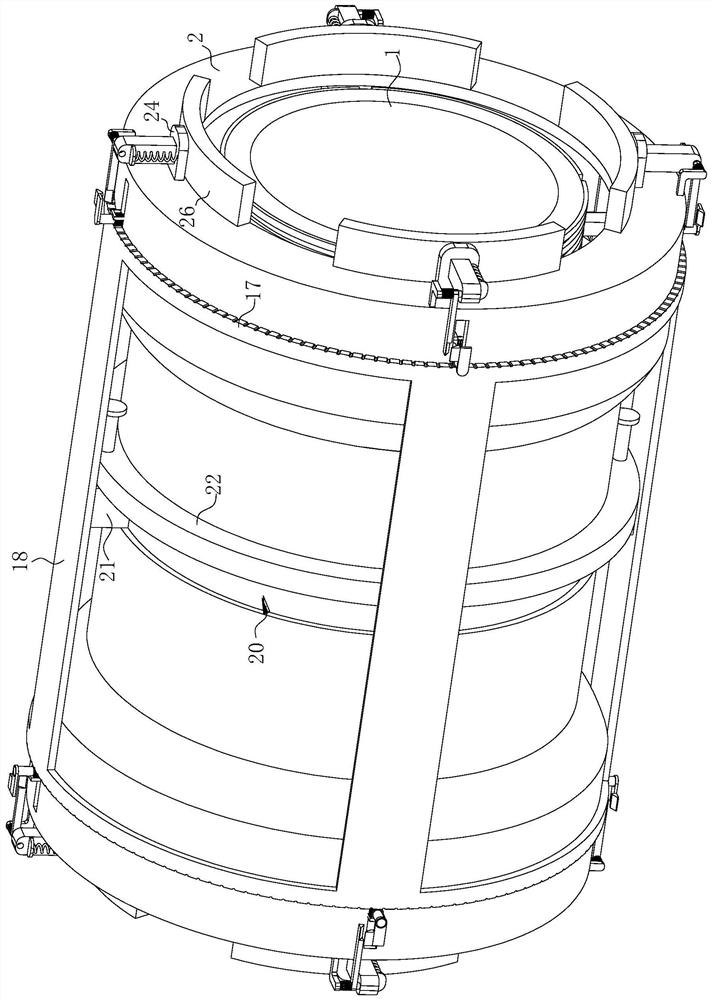

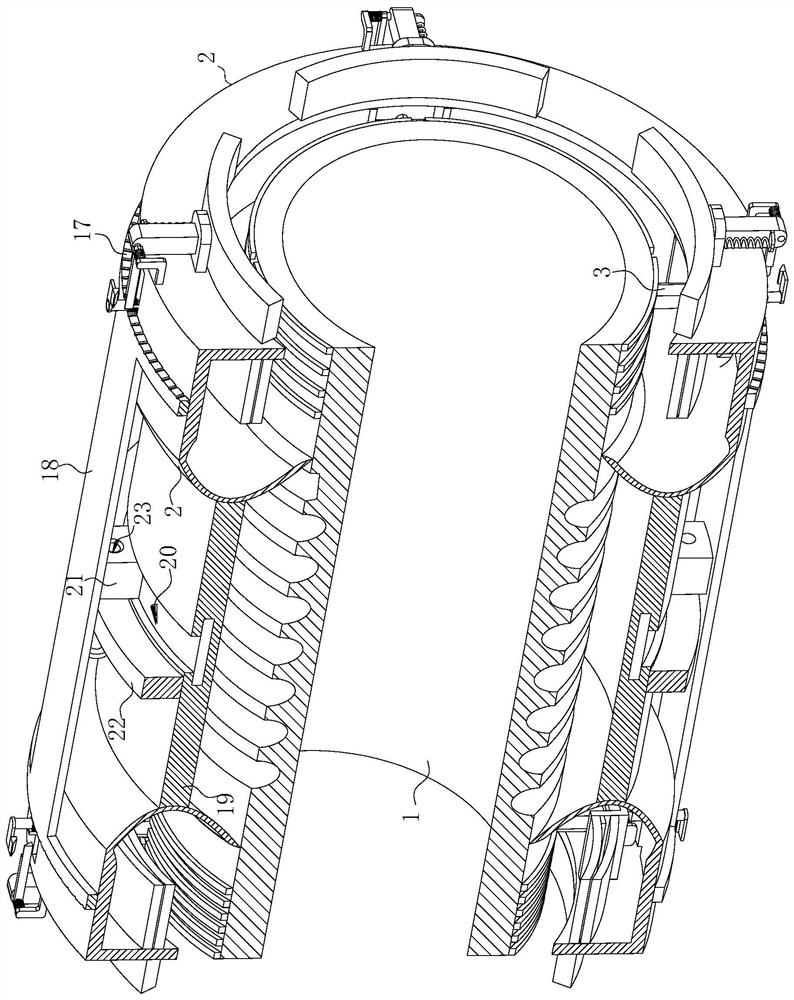

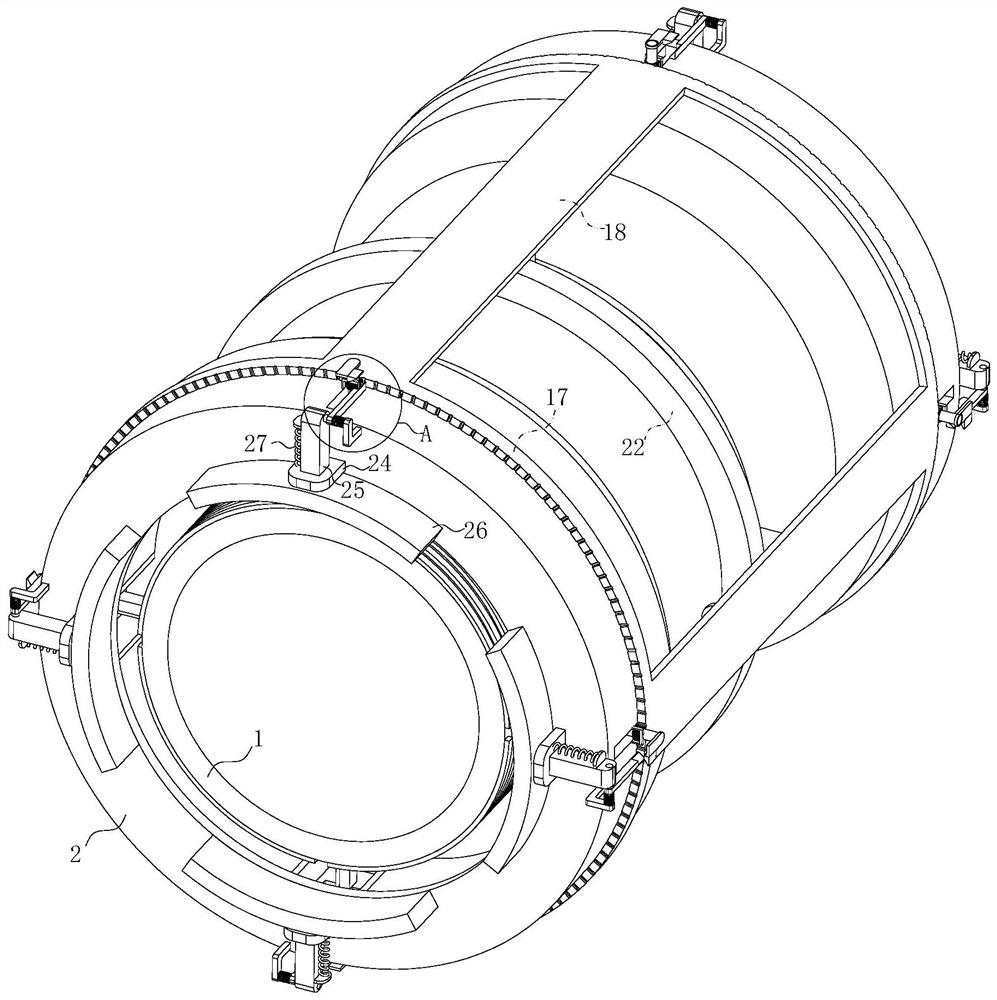

[0028] see Figure 1-8 , the present invention provides a technical solution: a hose compensator with firm connection, including a first through pipe 1, two guide pipes 2 are fixedly connected to the outer surface of the first through pipe 1, and the two guide pipes 2 are respectively fixed Connected to the left and right sides of the first through pipe 1, the inner end of the guide pipe 2 is arc-shaped for bending the incoming hose, and the outer surface of the first through pipe 1 is fixedly connected with several The circumferentially distributed dividing knife 3 is used to insert the hose between the guide tube 2 and the first through tube 1, and a compression mechanism for compressing the cut hose is provided between the guide tube 2 and the first through tube 1;

[0029] The pressing mechanism consists of several sets of pressing groups distributed in a circular array along the first through pipe 1. Each pressing group includes a first slide bar 4, and the first slide ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com