Low-pressure circulating barrel

A low-pressure circulation tank and tank body technology, which is applied in the direction of fluid circulation arrangement, damage protection, refrigeration safety arrangement, etc., can solve the problems of complex operation, large loss of ammonia liquid, error-prone and other problems, so as to ensure recovery efficiency, reduce resistance loss, Reduce the effect of frost fog

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

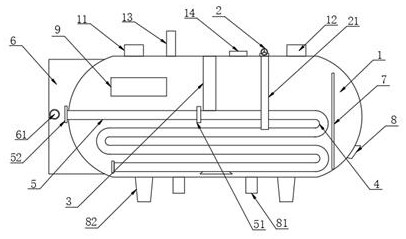

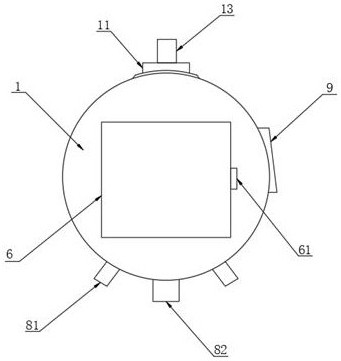

[0018] according to Figure 1-2 A kind of low-pressure circulating barrel shown, comprises barrel body 1, and barrel body 1 top is provided with air inlet 11 and air outlet 12, and between air inlet 11 and air outlet 12, is provided with backflushing port 13, inside barrel body 1 An injection pipe 3 is provided, the bottom of the injection pipe 3 is connected with a conveying pipe 4, one end of the conveying pipe 4 is connected with an external connecting pipe 5, an external connection box 6 is fixed on the outside of the barrel body 1, and a plurality of liquid level gauges 7 are uniformly arranged inside the barrel body 1 , The outer surface of the barrel body 1 is provided with a refueling port 8, and the front side surface of the barrel body 1 is provided with a control panel 9.

[0019] Between the air inlet 11 and the air outlet 12, a backwash port 13 is provided, and a safety valve 14 is provided on one side of the backwash port 13. The air inlet 11, the air outlet 12, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com