Refrigerator

A refrigerator and air inlet duct technology, applied in the field of refrigeration equipment, can solve the problems of limited defrosting effect, complex air duct structure, aggravated frosting, etc., and achieve the effects of large space utilization rate, improved energy saving efficiency, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

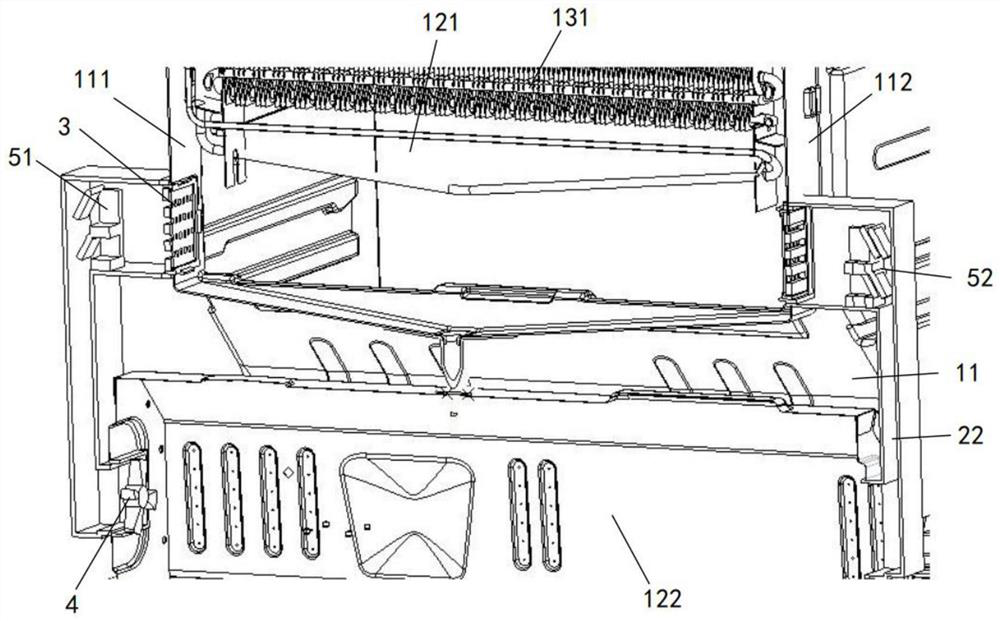

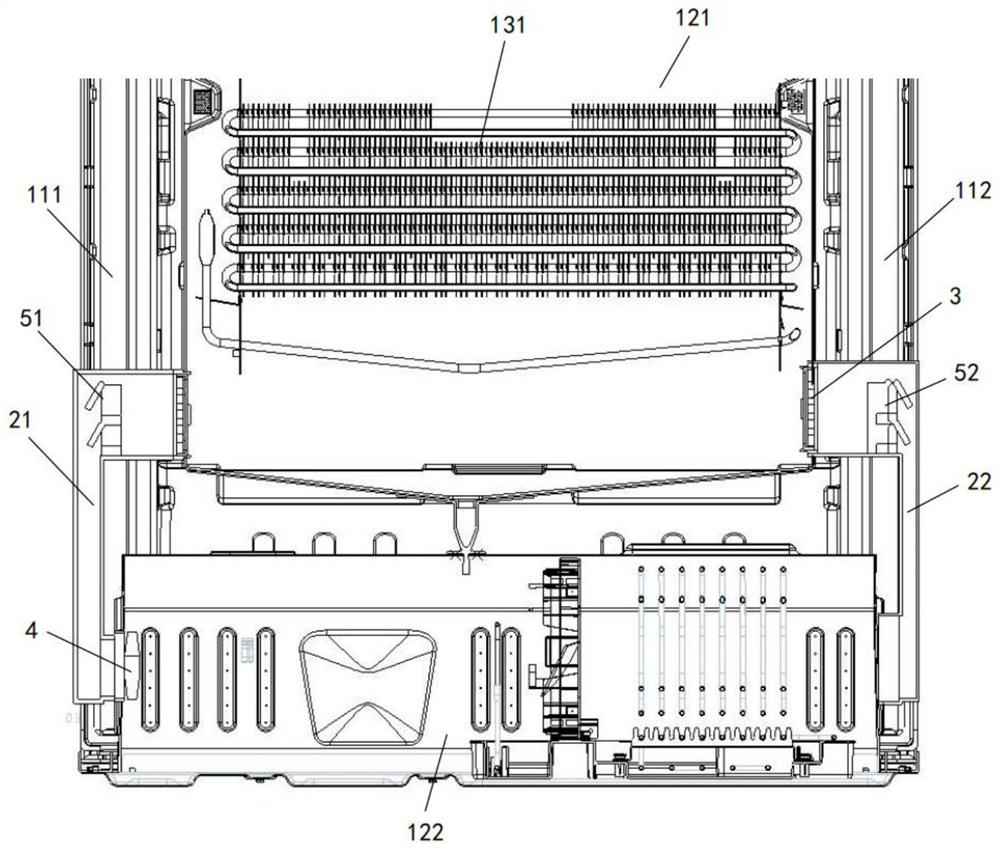

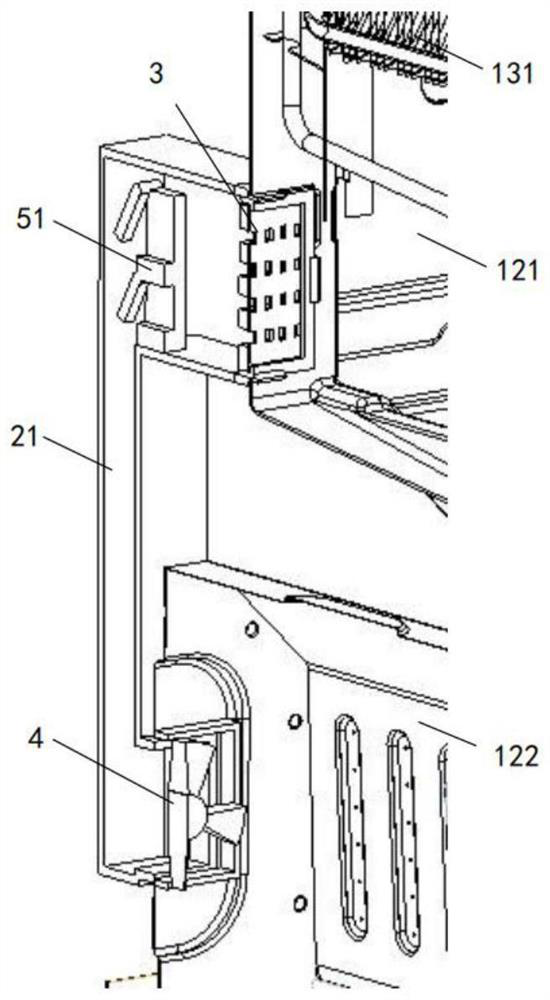

[0054] Such as Figure 1a and Figure 1b As shown, this embodiment provides a refrigerator, and the refrigerator includes a first compartment 121, a second compartment 122 arranged along the height direction of the refrigerator, and an air inlet duct 21 and a return duct connecting the first compartment 121 and the second compartment 122. Air duct 22; the first chamber 121 accommodates the evaporator 131, the second chamber 122 accommodates the compressor, and the air inlet duct 21 and the return air duct 22 are relatively arranged between the first compartment 121 and the second compartment 122 ; The air inlet channel 21 is used to send the hot and humid air in the second room 122 into the first room 121; the air return channel 22 is used to send the defrosted air in the first room 121 into the second room 122; the air inlet duct 21 and the air return duct 22 are provided with control dampers;

[0055] At least one of the air inlet channel 21 and the air return channel 22 is...

Embodiment 2

[0077] The difference from Embodiment 1 is that the dehumidification assembly 3 includes a plurality of baffles arranged at intervals along the first air inlet or the first air outlet; the plurality of baffles form an angle α with the flow direction of the air, where 0° <α<90°; a water receiving tank is provided under the multiple baffles; a second flow channel is formed between adjacent baffles;

[0078] When the refrigerator is in the defrosting mode, when the hot and humid air flows through the second flow channel, the water vapor in it collides with the baffle and coalesces into water droplets, and then drops into the water receiving tank along the baffle, so that the hot and humid air is transformed into The hot air is dried, and then the evaporator 131 is defrosted to improve the defrosting effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com