Battery shock resistance detection device

A detection device and shock resistance technology, applied in the field of battery shock resistance detection devices, can solve the problems of inability to accurately obtain test data, difficult to control the amplitude of spring swing, wrong test data, etc., and to change the test vibration amplitude and Test time, improve work efficiency, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

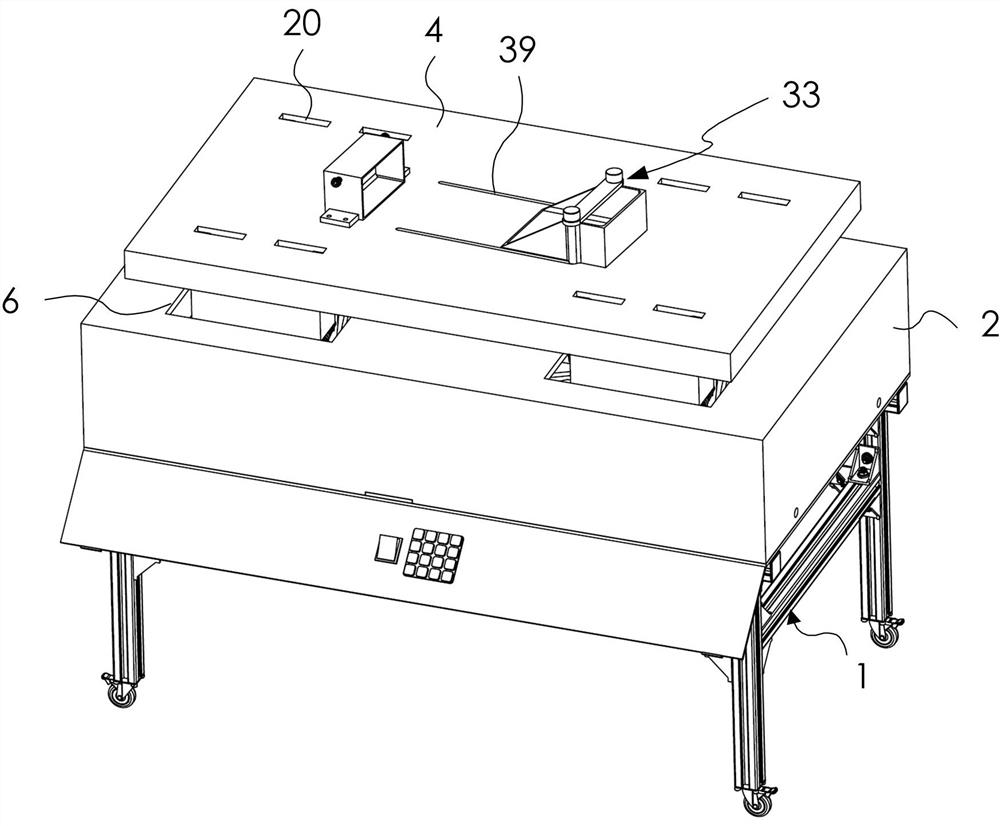

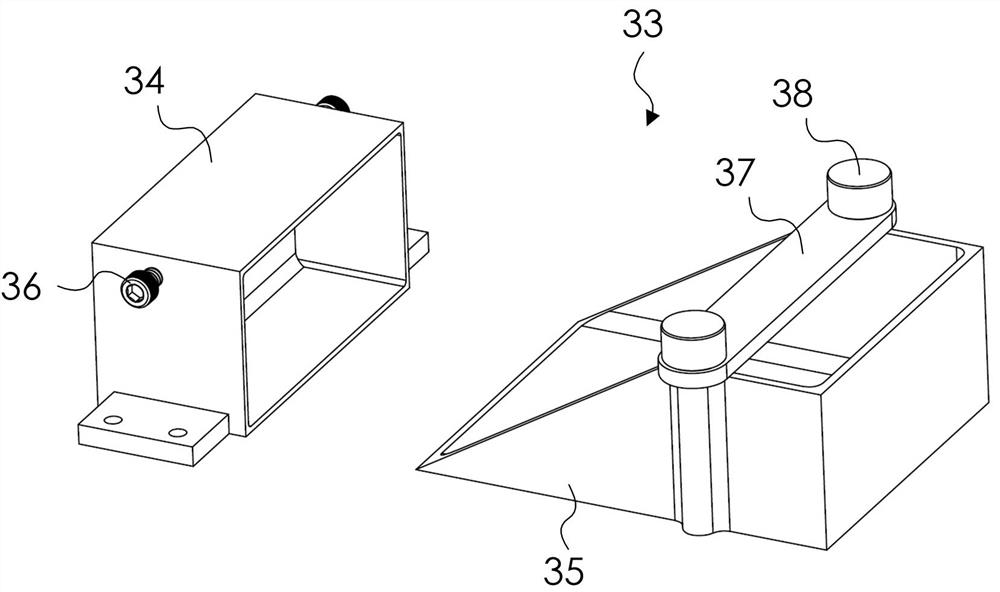

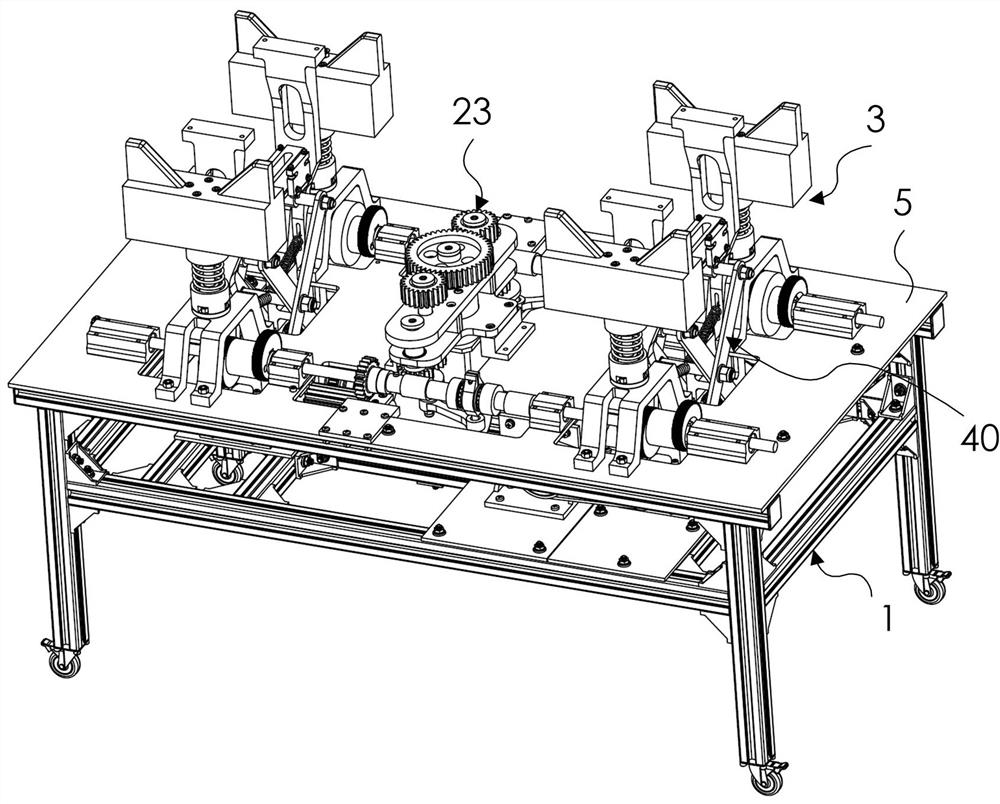

[0037] Such as Figure 1 to Figure 11 As shown, the battery shock resistance testing device of the present invention includes a workbench 1 , an outer cover 2 , a transmission mechanism 3 and a support plate 4 . There is a control panel on the workbench 1, and the control panel is used to control the entire detection device. The working plate 5 arranged on the workbench 1 is fixed on the workbench 1 and separates the upper and lower layers of the workbench 1 so that the motor is at the lower end. Outer cover 2 is installed on the working board 5, and outer cover 2 is used for protecting the internal mechanism, avoids being exposed outside and causing injury to the staff. There is a through hole 6 on the outer cover 2, and the through hole 6 communicates the outside with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com