Pluggable electrode and insulating oil discharge test device

A technology of discharge test and insulating oil, applied in the direction of measuring device, measuring device casing, measuring electricity, etc., can solve the problems of consumption, multi-metal material and processing time, inconvenient replacement and installation process, etc., to reduce manufacturing cost and save production. Material, the effect of speeding up the replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

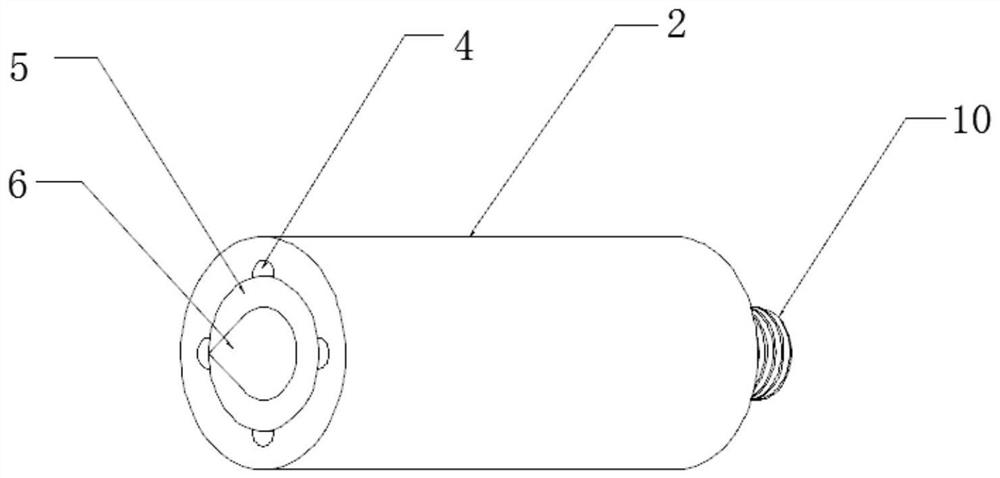

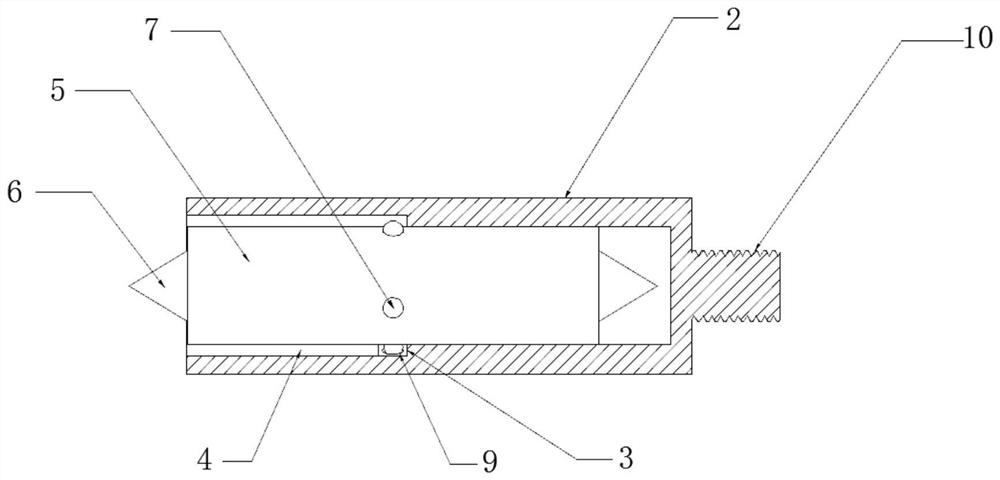

[0027] Such as figure 1 The schematic diagram of the structure of the pluggable electrode 1 shown, the electrode includes:

[0028] The electrode tube 2 has a plurality of limiting grooves 3 along the circumference, and a plurality of guide grooves 4 along the axial direction. One end of all the guide grooves 4 communicates with different limiting grooves 3, and the other end extends to the At the nozzle at one end of the electrode tube 2;

[0029] The electrode rod 5 is provided with an electrode head 6 at the end, and a plurality of positioning beads 7 are provided on the side wall. During assembly, all the positioning beads 7 are respectively snapped into different limiting grooves 3 along the corresponding guide grooves 4 .

[0030] Specifically, the electrode tube 2 can be a conductive copper tube, and four limiting grooves 3 are evenly opened on the inner wall surface of the electrode tube 2. These four limiting grooves 3 surround the central axis of the electrode tube ...

Embodiment 2

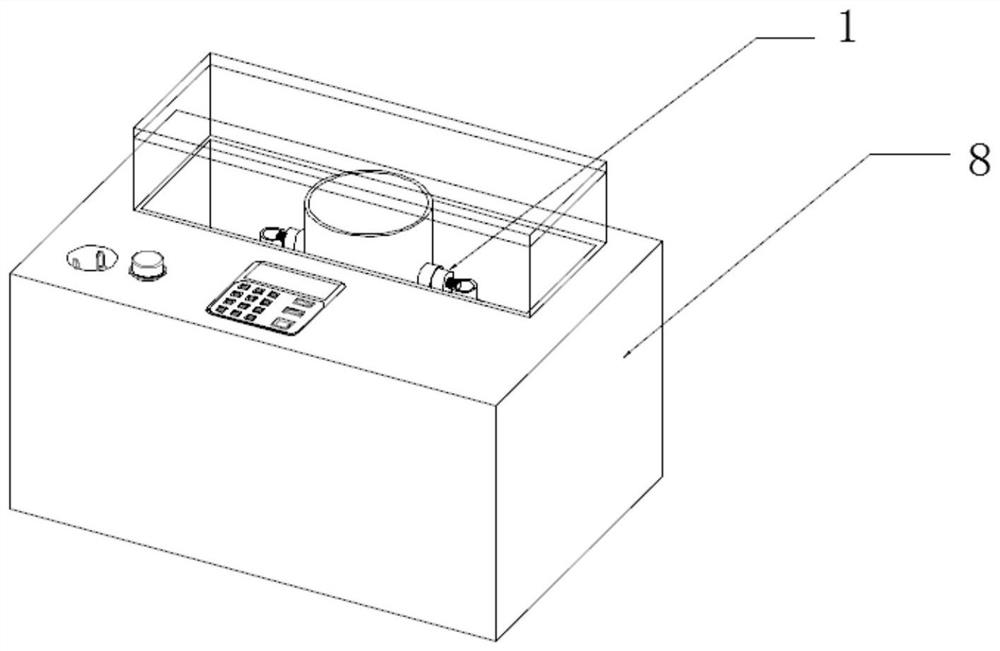

[0045]As shown in the schematic diagram of the structure of the insulating oil discharge test device, the test device includes a test box 8, and the test box 8 is equipped with a pluggable electrode 1, and the pluggable electrode 1 includes:

[0046] The electrode tube 2 has a plurality of limiting grooves 3 along the circumference, and a plurality of guide grooves 4 along the axial direction. One end of all the guide grooves 4 communicates with different limiting grooves 3, and the other end extends to the At the nozzle at one end of the electrode tube 2;

[0047] The electrode rod 5 is provided with an electrode head 6 at the end, and a plurality of positioning beads 7 are provided on the side wall. During assembly, all the positioning beads 7 are respectively snapped into different limiting grooves 3 along the corresponding guide grooves 4 .

[0048] Specifically, the electrode tube 2 can be a conductive copper tube, and four limiting grooves 3 are evenly opened on the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com