Method of improving outline of photoresist pattern

A technology of photoresist and photoresist layer, which is applied in the field of improving the profile of photoresist, and can solve problems such as top-view inspection results that are out of specification and unable to meet specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

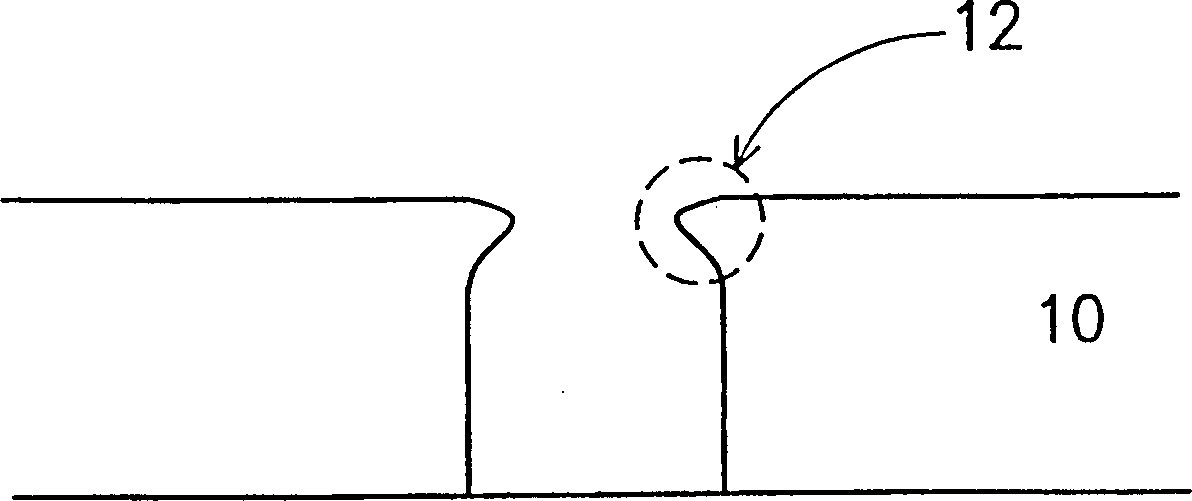

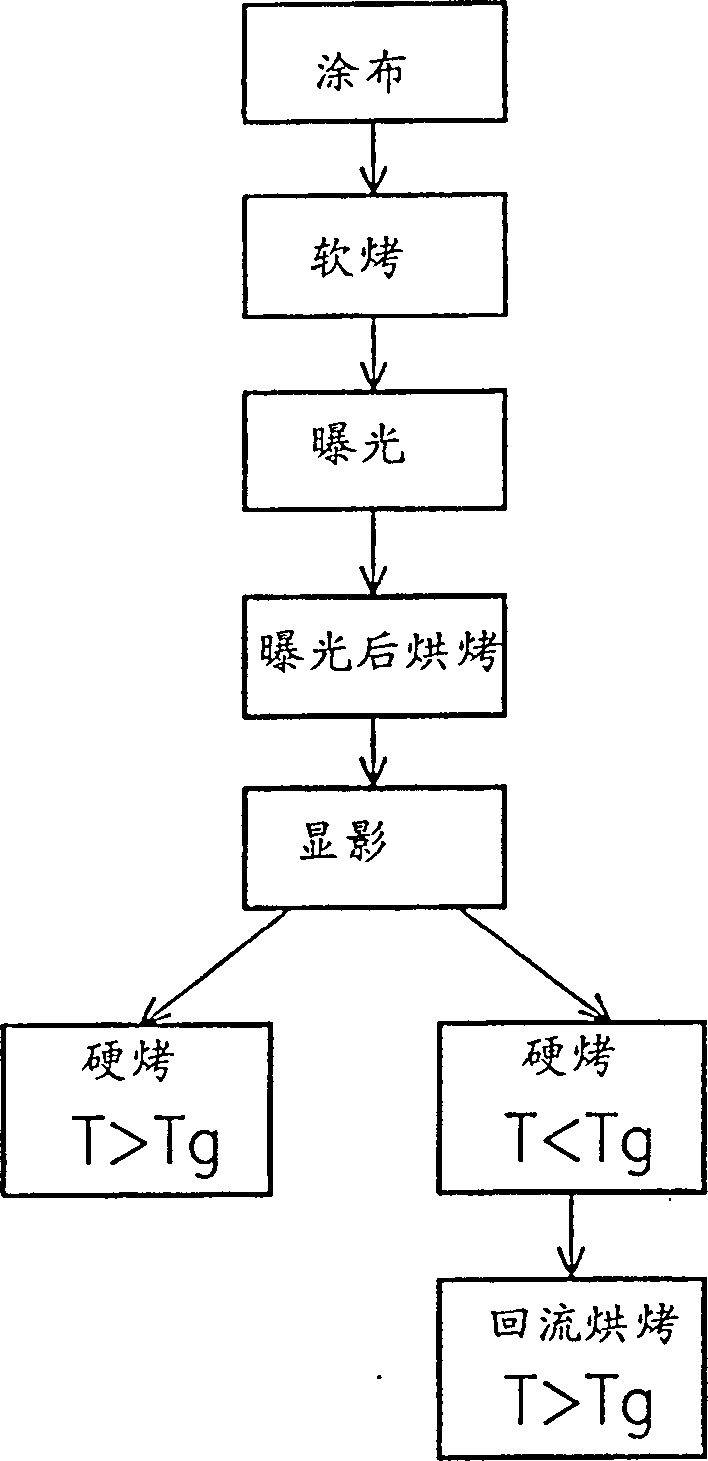

[0023] With the rapid development of semiconductor components and manufacturing processes, the size of the contact window has been reduced to 0.18 microns or smaller. Therefore, in order to improve the manufacturing process margin (Depthof Focus) higher than 0.6 microns in mass production ( Process) becomes quite difficult. In the general manufacture of contact windows, a photoresist layer is usually formed to define the pattern under the photoresist layer. For smaller contact windows, thermal reflow can be achieved by controlling the reflow temperature. A larger depth of focus is achieved, and a lower mask error factor (Mask Error Factor, MEF) is obtained to improve the profile of the photoresist. The present invention is a method of using thermal reflow to improve the defined profile of photoresists.

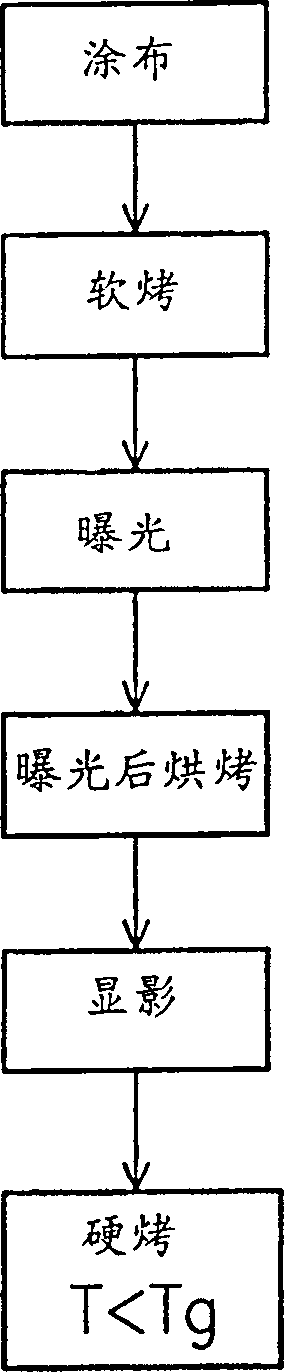

[0024] Please refer to figure 2 , which shows the flow of a method for improving the profile of a photoresist according to an embodiment of the present invention, and ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com