Turbine module for propeller with variable pitch blades and turbine comprising module

A technology of propellers and turbines, applied in the field of pitch mechanism, to achieve a good effect of relative error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

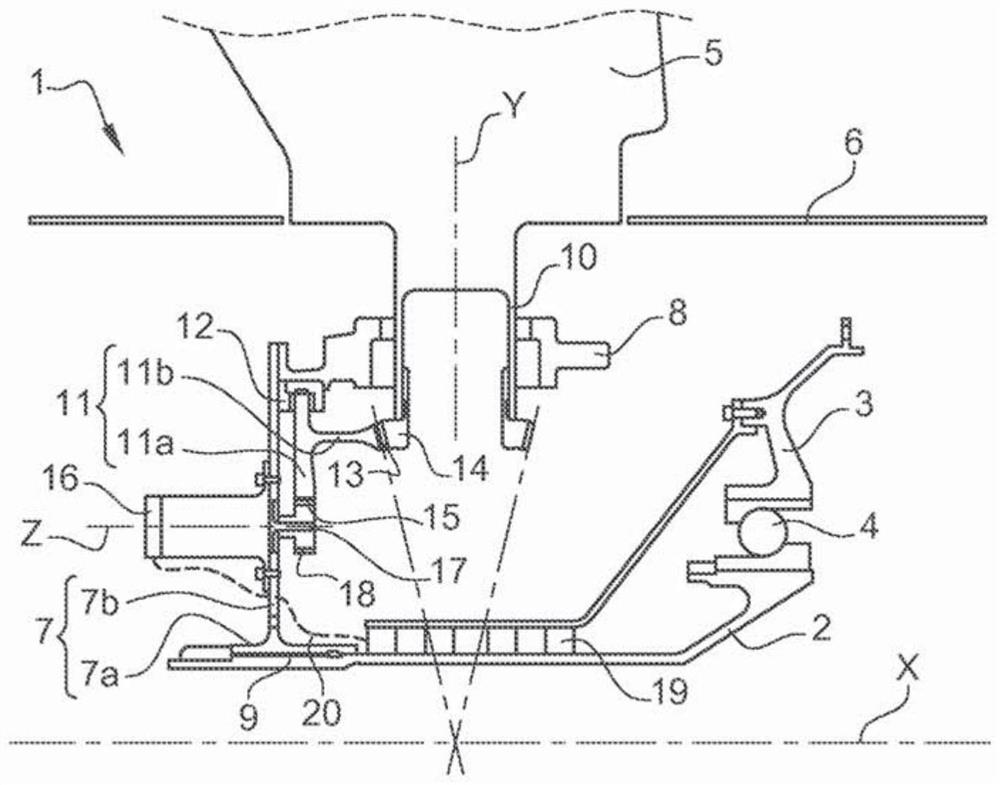

[0039] figure 1 A general view is shown of an embodiment of a device 1 according to the invention, which is rotatably driven about the longitudinal axis X of the turbine by means of a shaft 2 extending from an engine part (not shown). The shaft 2 itself is rotatably guided on the stationary housing 3 of the turbine by means of bearings 4 . The propeller is placed in front of the engine. The blades 5 of the propeller are rotatably driven about a longitudinal axis X and are designed to each have a variable pitch about a radial axis Y with which the propeller rotates. The cover 6 isolates the device itself from the airflow in which the blades 5 of the propeller work.

[0040] The device 1 comprises a trunnion 7 centred on the longitudinal axis X which connects the shaft 2 to the hub 8 of the propeller which supports the blades 5 . The trunnion 7 includes a substantially cylindrical central portion 7a fitted to the shaft 2 . The connection piece 9 is made of splines, which ena...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com