Interruption unit having vacuum tube and insulating housing

A technology of insulating housing and interrupting unit, applied in high-voltage air circuit breakers, electrical components, high-voltage/high-current switches, etc., can solve problems such as erosion of insulating housing materials, and achieve the effect of improving service life and operational reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

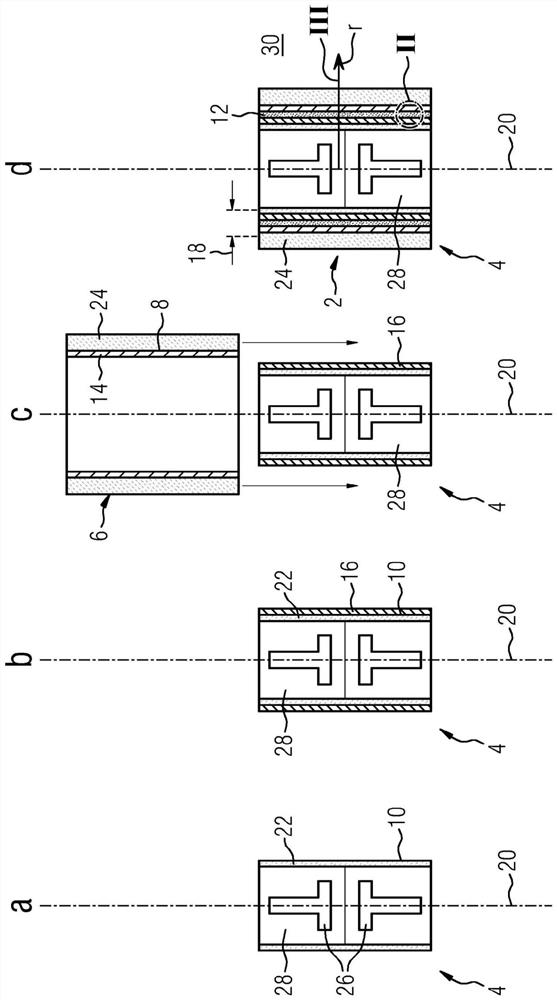

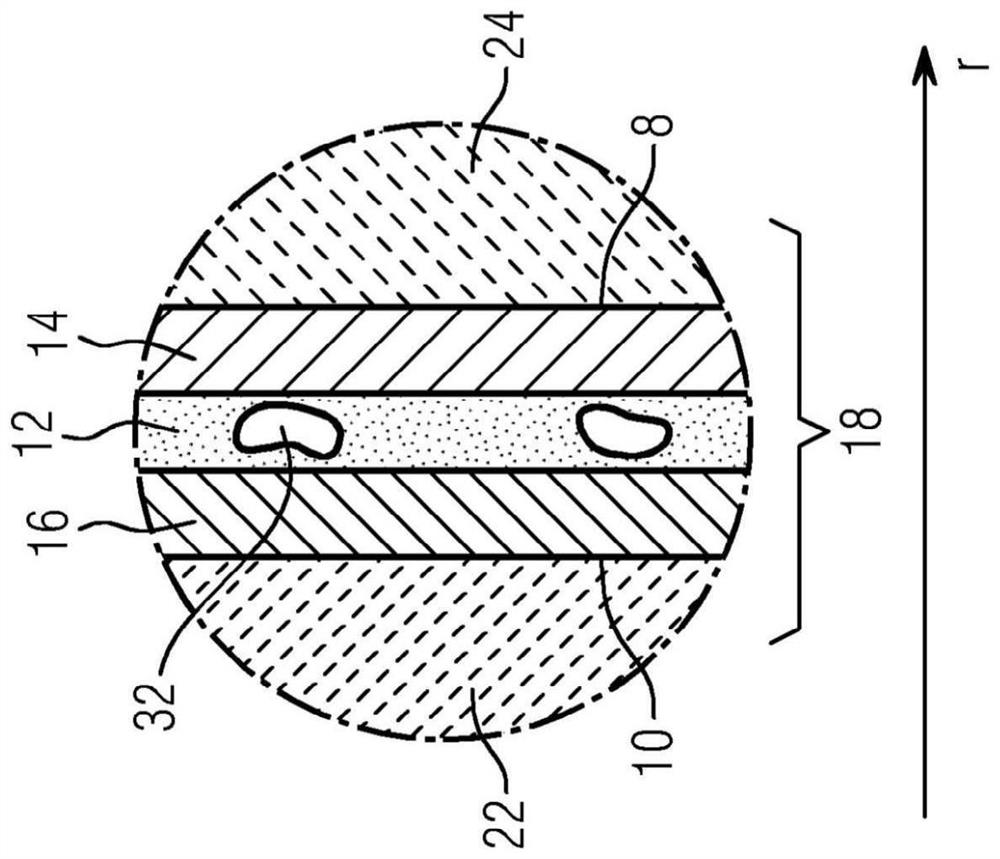

[0015] exist figure 1 The structure or formation of the interruption unit 2 with the vacuum interrupter 4 and the insulating housing 6 is shown in . In the leftmost illustration according to a, a vacuum interrupter 4 is shown which has a structural material 22 which surrounds a vacuum chamber 28 . Two switching contacts 26 are shown schematically in the vacuum chamber 28 , at least one of which is movable in translation along the switching axis 20 . Here, the outer configuration of the vacuum interrupter 4 is to be understood purely schematically, the structural material 22 usually consisting of an insulating ceramic material or comprising this insulating ceramic material generally only representing a part of the housing of the vacuum interrupter 4 . In particular in the region of the movement of the switching contact 26 along the switching axis 20 , the vacuum interrupter 4 is delimited on the outside by a metallic outer material.

[0016] In addition, according to figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com