A kind of stainless steel room temperature chemical polishing liquid and polishing process

A chemical polishing and stainless steel technology, applied in the field of polishing, can solve the problems of inability to ensure the size change of the workpiece, water pollution, air pollution, etc., and achieve the effects of easy control of the reaction process, obvious polishing effect, and simple waste liquid treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

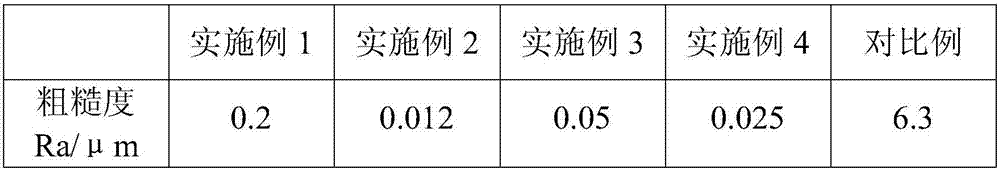

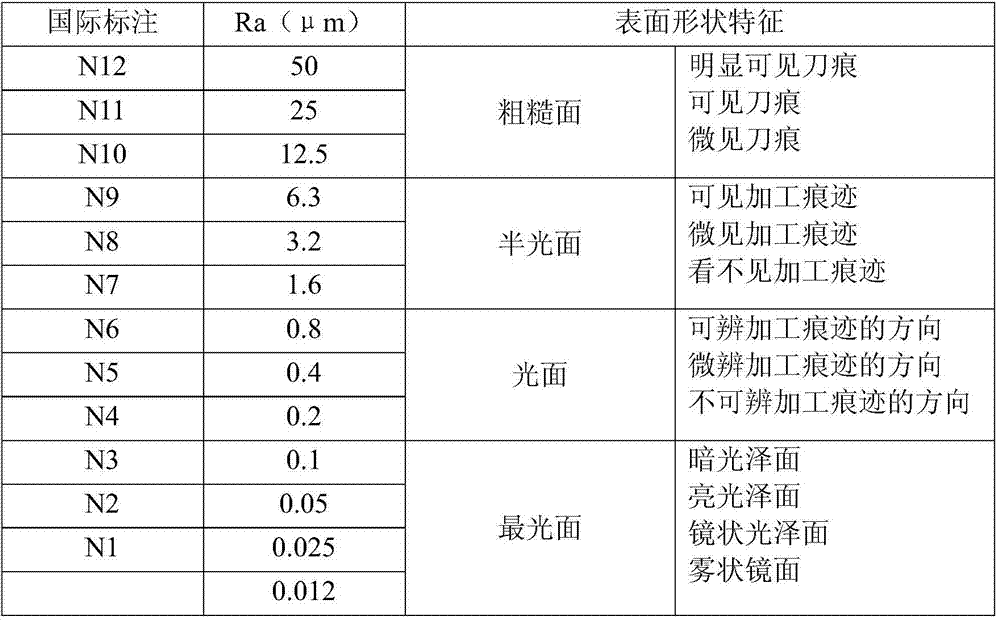

Examples

Embodiment 1

[0032] Treatment plan for stainless steel products with serious oil stains and scales:

[0033] A kind of stainless steel room temperature chemical polishing liquid, by weight percentage, comprises the following components:

[0034] Sulfuric acid 15%, oxalic acid 5%,

[0035] 10% hydrochloric acid, 1% glacial acetic acid,

[0036] Brightener 2%, the balance is water.

[0037] Polishing liquid application polishing process:

[0038] (1) Degreasing: due to the poor contact between the surface of the stainless steel product and the polishing liquid when there is serious oil pollution, the brightness of the polished surface is uneven. Therefore, the stainless steel product to be polished needs to be soaked in a degreasing agent for 7 minutes. ;

[0039] (2) Water washing: put the degreasing stainless steel product into running water and wash it for 1 minute;

[0040] (3) Pre-pickling: Since the reaction process between the surface of the stainless steel product and the polish...

Embodiment 2

[0046] Treatment plan for stainless steel products with serious oil stains and scales:

[0047] A kind of stainless steel room temperature chemical polishing liquid, by weight percentage, comprises the following components:

[0048] Sulfuric acid 18%, oxalic acid 6%,

[0049] 12% hydrochloric acid, 1% glacial acetic acid,

[0050] Brightener 2%, the balance is water.

[0051] Polishing liquid application polishing process:

[0052] (1) Degreasing: due to the poor contact between the surface of the stainless steel product and the polishing liquid when there is serious oil pollution, the brightness of the polished surface is uneven. Therefore, the stainless steel product to be polished should be soaked in a degreasing agent for 10 minutes. ;

[0053] (2) Water washing: put the degreasing treated stainless steel product into running water and wash it for 3 minutes;

[0054] (3) Pre-pickling: Since the reaction process between the surface of the stainless steel product and th...

Embodiment 3

[0061] Treatment plan for stainless steel products without serious oil stains and scales:

[0062] A kind of stainless steel room temperature chemical polishing liquid, by weight percentage, comprises the following components:

[0063] Sulfuric acid 10%, oxalic acid 6%,

[0064] 12% hydrochloric acid, 1% glacial acetic acid,

[0065] Brightener 2%, the balance is water.

[0066] Polishing liquid application polishing process:

[0067] (1) Chemical polishing: soak the stainless steel product to be polished in chemical polishing solution for 8 minutes. The brightener of the polishing liquid contains degreasing ingredients and the polishing liquid has the effect of descaling. Therefore, for stainless steel products that are not very serious about oil stains and scales, the steps of degreasing and pre-pickling can be directly polished. When polishing stainless steel products There should be a certain distance (about 1cm) between them so that the stainless steel products can fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com