Composite sacrificial anode on outer wall of bushing

A sacrificial anode and sleeve technology, applied in the field of metal anti-corrosion, can solve the problems of poor uniformity of alloy dissolution, health and environmental hazards, and local corrosion, and achieve the effects of good anti-corrosion protection effect, significant economic benefits and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: Taking a composite sacrificial anode on the outer wall of a casing as an example, the present invention is further described in detail.

[0015] The composition of the outer layer magnesium alloy of the composite sacrificial anode is: Al: 1.0%, Zn: 0.3%, Ca: 0.1%, Mn: 0.03%, and the balance is magnesium; the inner layer aluminum alloy of the composite sacrificial anode is each The composition by weight percentage is: Zn: 3.0%, In: 0.1%, Sn: 0.05%, Si: 0.05%, Ti: 0.03%, and the balance is aluminum; the sum of the weight percentages of each component is 100%. A composite sacrificial anode material is prepared by combining the inner and outer double-layer anodes tightly by a conventional casting method.

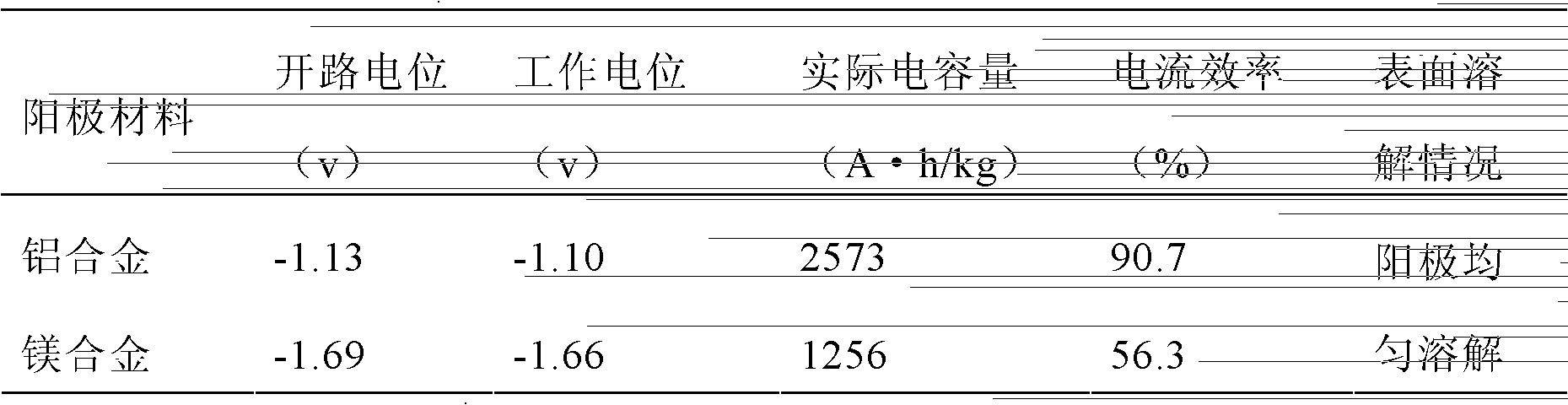

[0016] Electrochemical performance tests were carried out on the prepared anode materials. Referring to the provisions of the standard GB / T17848-1999, the Princeton electrochemical comprehensive test system was used to perform electrochemical performance tes...

Embodiment 2

[0021] The composition of the outer layer magnesium alloy of the composite sacrificial anode is: Al: 1.5%, Zn: 0.1%, Ca: 0.3%, Mn: 0.05%, and the balance is magnesium; the inner layer of the composite sacrificial anode is aluminum alloy. The composition by weight percentage is: Zn: 3.5%, In: 0.15%, Sn: 0.03%, Si: 0.1%, Ti: 0.05%, and the balance is aluminum; the sum of the weight percentages of each component is 100%. A composite sacrificial anode material is prepared by combining the inner and outer double-layer anodes tightly by a conventional casting method.

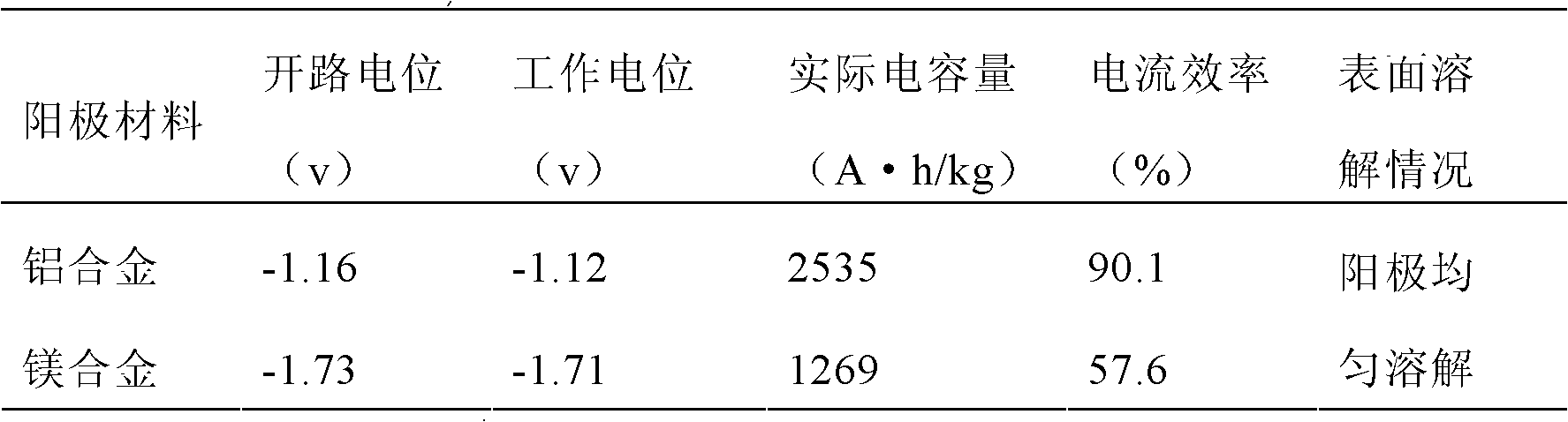

[0022] Using the same method as in Example 1, the electrochemical performance test of the prepared anode material was carried out.

[0023] Test medium: natural seawater, test temperature: 60°C

[0024] Anode electrochemical performance test results:

[0025]

[0026] The above experiments show that the anode material prepared by the present invention fully combines the advantages of the two anode materials, ther...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com