Multifunctional no-tillage planter

A seeder and multi-functional technology, which is applied to agricultural machinery and implements, shovels, plows, etc., can solve the problems of increased operating costs, inability to ensure the accuracy of sowing and fertilization, and waste of man-hours, and achieve the effect of ensuring the effect of covering soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention can be that a group of operating units is installed on the tractor, and it can also be that multiple groups of operating units are installed on the tractor for operation. The specific situation can be determined according to the actual size of the land to be cultivated. Below, a group of operating units is installed on the tractor Described as an example.

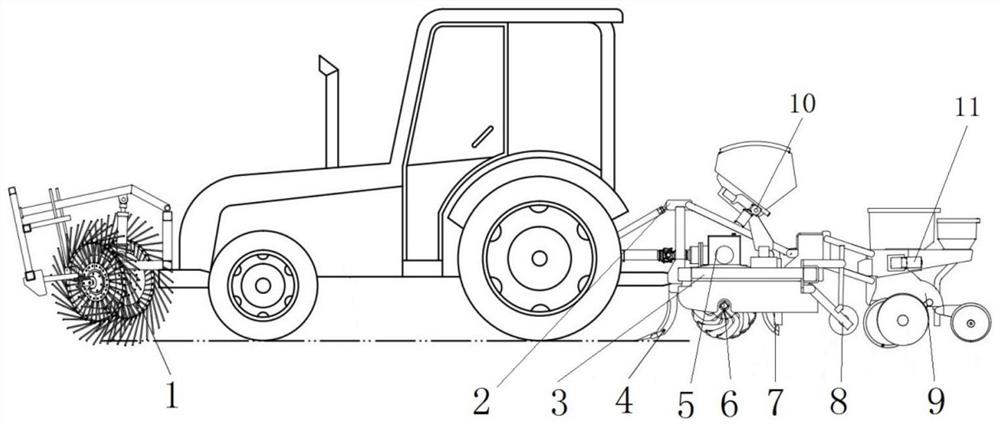

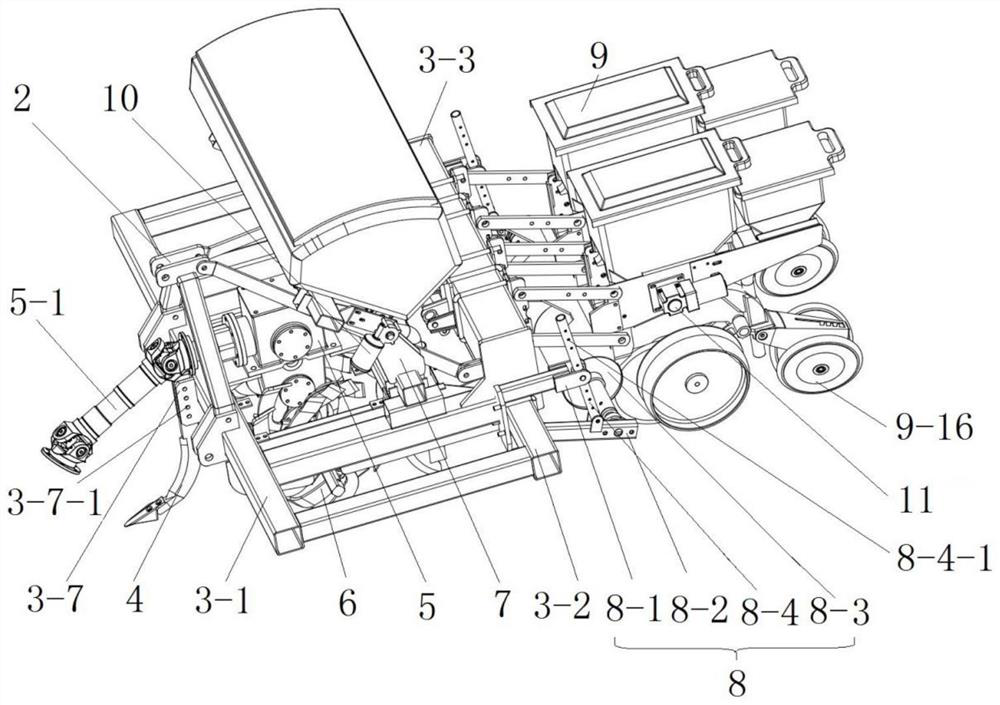

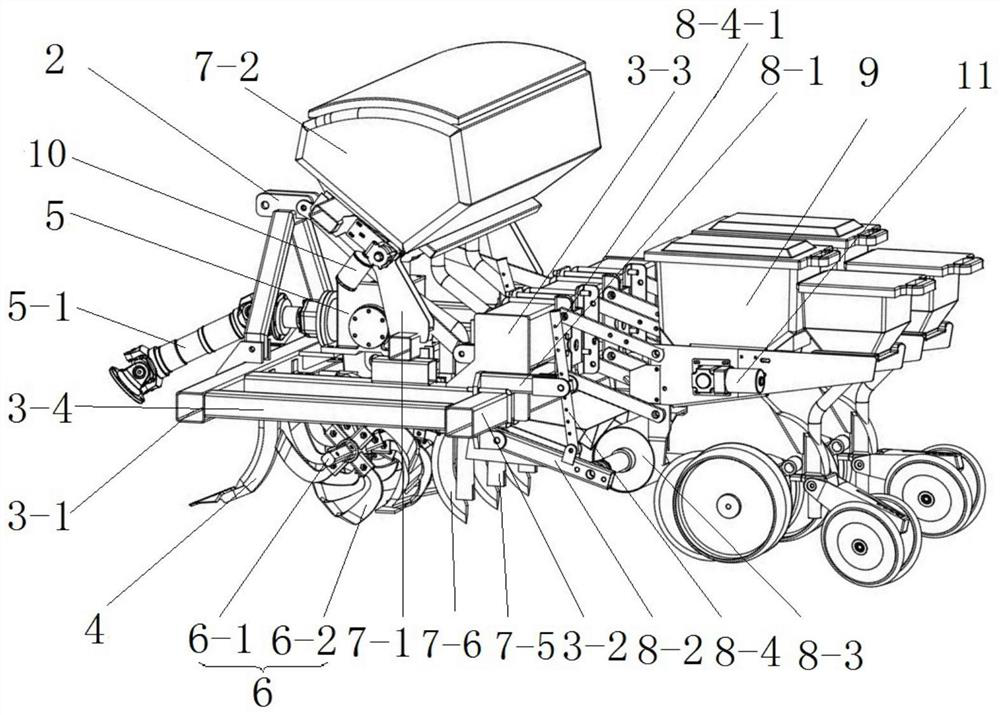

[0032] like figure 1 , figure 2 , image 3 and Figure 5 As shown, a multifunctional no-tillage seeder includes a control system and at least one group of operating units, the control system includes a controller, a speed sensor, a fertilizer discharge motor 10 and a seeding motor 11, and a group of operating units includes A returning machine 1, a subsoiling shovel 4, a broken soil structure 6, a fertilizing structure 7, a suppression structure 8 and a seeding structure 9, the returning machine 1 is fixed on the front end of the tractor, and the driving of the tractor A controller is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com