Stone powder separation system for stone sewage and working method

A separation system and stone powder technology, applied in the field of stone processing, can solve the problems of inability to separate stone powder, collect stone powder and purify sewage at the same time, high maintenance costs and production costs, increase economic costs, etc., to achieve industrial water circulation, maintenance costs and The effect of low production cost and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

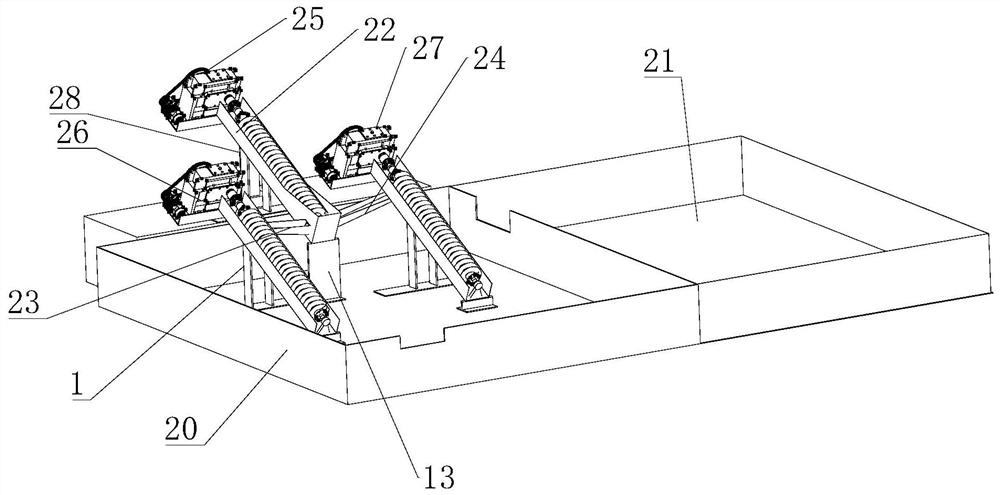

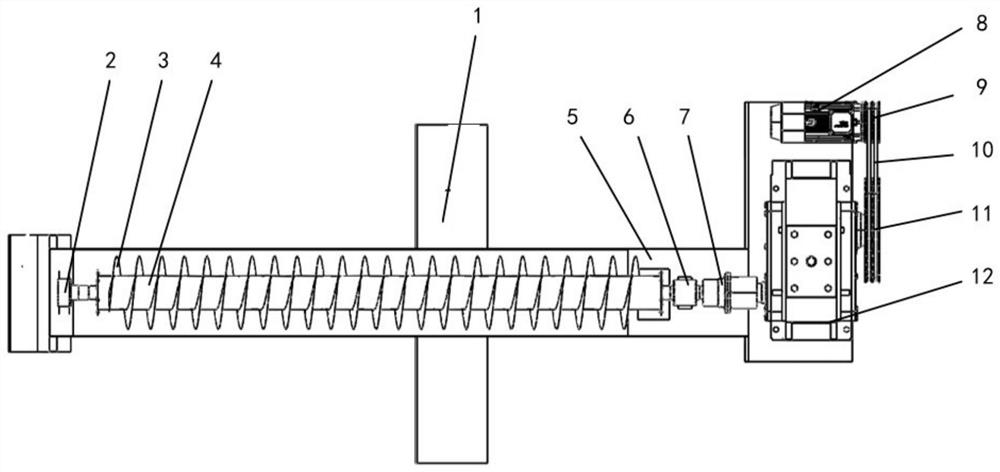

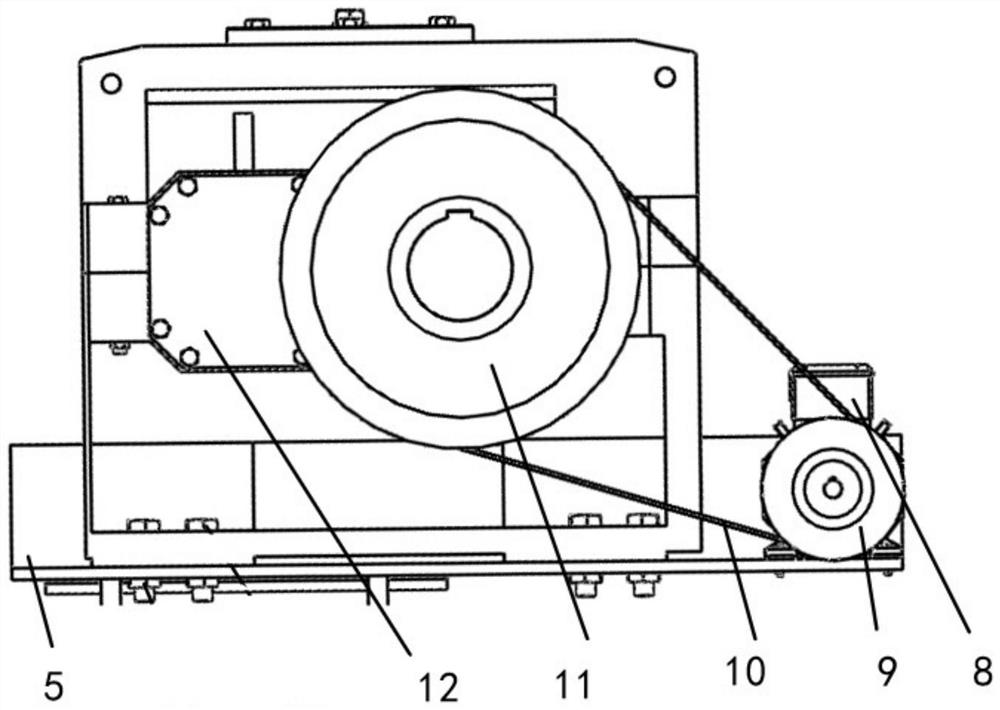

[0048] As an embodiment, it also includes a second separation device 27, the second separation device 27 includes a third support mechanism, a third screw mechanism and a third drive mechanism, the third support mechanism has the same structure as the first support mechanism, the third The support mechanism is provided with a third connecting groove; the second separation device 27 is symmetrically arranged on both sides of the stone powder separation device with the first separation device 26 , and the second separation device 27 is connected with the stone powder separation device through the second transfer frame 24 .

[0049] Specifically, the structure composition and working principle of the second separating device 27 and the first separating device 26 are completely the same, and only the first separating device 26 will be introduced below.

[0050] By setting two sets of separation devices and one stone powder collection device 25 connected through the transfer frame, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com