Anti-tipping mechanism of a crane

A crane and anti-overturning technology, which is applied to the bottom support structure, hoisting device, load hanging components, etc., can solve the problems of crane vehicle loss of balance, vehicle overturning, accidents, etc., to prevent overturning and reduce settlement , The effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

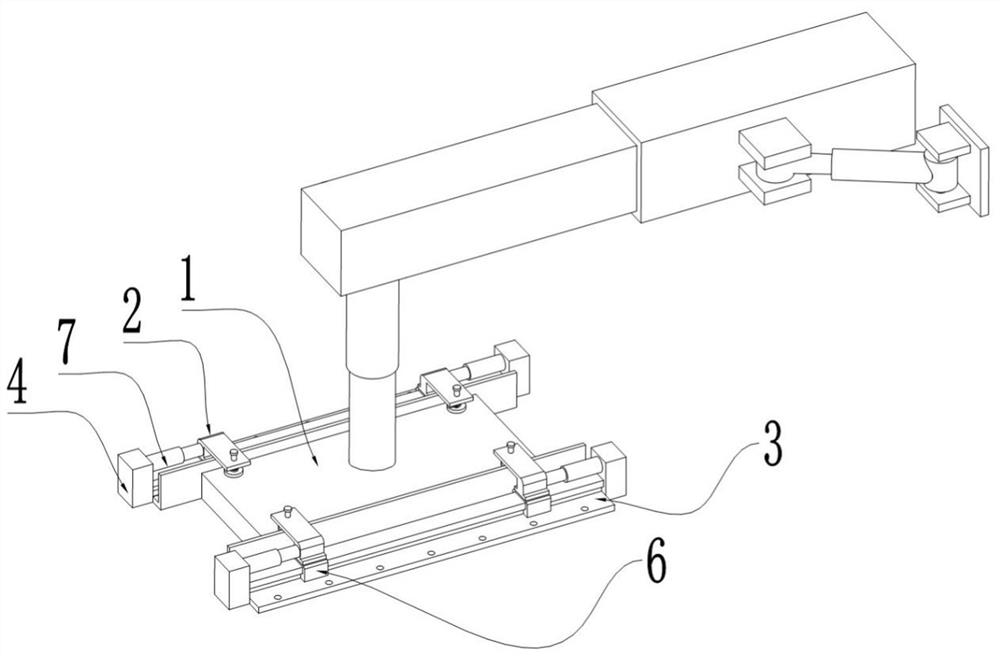

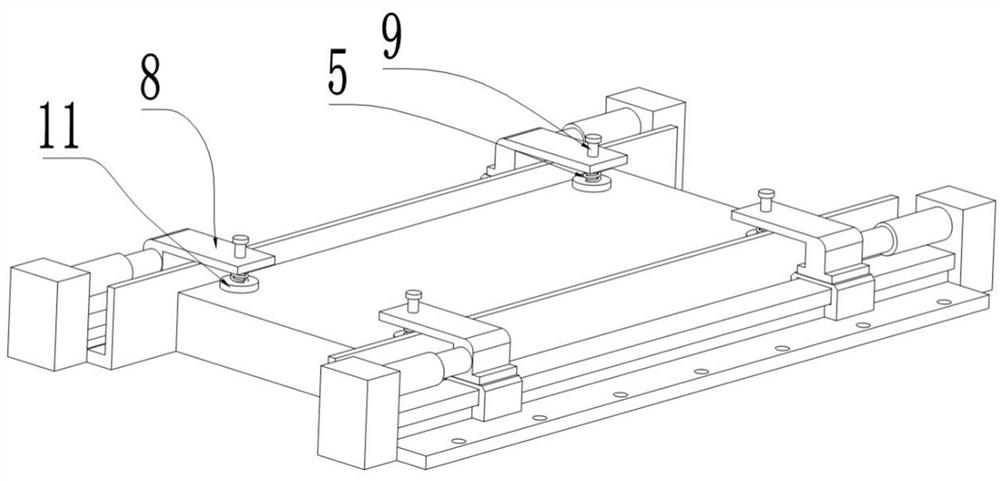

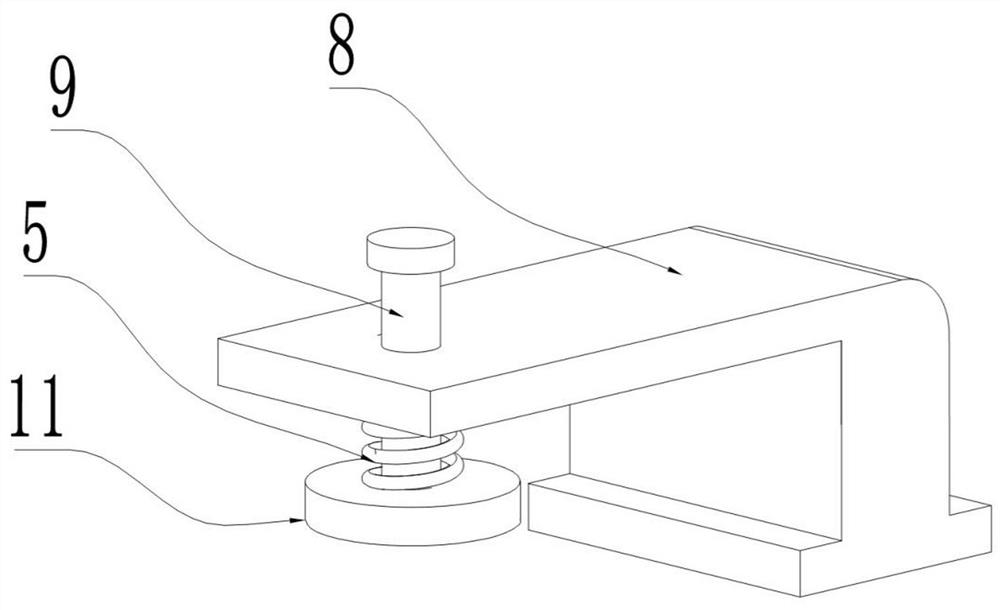

Embodiment 1

[0028] refer to Figure 1-5 , an anti-tipping mechanism for a crane, comprising a crane outrigger, a base 1 connected to the bottom of the crane outrigger, a horizontal telescopic assembly hinged on the top of the crane outrigger through a hinge assembly, the base 1 is made of ferromagnetic material, and both sides of the base 1 are provided with There is a protective mechanism 2, and the protective mechanism 2 includes an I-shaped slide rail 3, and the first slider 6 is slidably connected to both sides of the I-shaped slide rail 3, and the two ends of the I-shaped slide rail 3 are fixed with limit blocks 4, and The bottom of the glyph-shaped slide rail 3 is connected to the ground, the first electric telescopic rod 7 is arranged between the limit block 4 and the first slider 6, and the top of the first slider 6 is fixedly connected with an "L"-shaped docking block 8, The end of the docking block 8 away from the I-shaped slide rail 3 is provided with an electromagnetic roller ...

Embodiment 2

[0037] Based on the previous embodiment, although the above-mentioned device can play the role of anti-tipping, the above-mentioned device can only be applied to the crane with the outrigger base 1 and the hydraulic support leg fixedly connected, but because the base 1 and the hydraulic support leg in the prior art Most of them are hinged, and the tipping process of the crane with hinged joints between the base 1 and the hydraulic support legs is as follows. Since the base 1 is hinged with the outriggers, after the whole crane tilts, one of the outriggers on one side of the crane tilts off the ground first, and the other outrigger The side still keeps in contact with the ground and the angle between the outrigger on the other side and the outrigger base 1 is relatively large, until the outrigger on the other side is tilted off the ground, and finally the phenomenon of rollover occurs; The supporting legs are hinged cranes to prevent tipping during the tilting process; at the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com