High-pressure ozone generator device

An ozone generator and high-pressure ozone technology, applied in ozone preparation, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of easy ozone emission, affecting the disinfecting efficiency, inconvenient ozone generator, etc., to avoid doping impurities , the effect of expanding the efficiency and purifying the air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

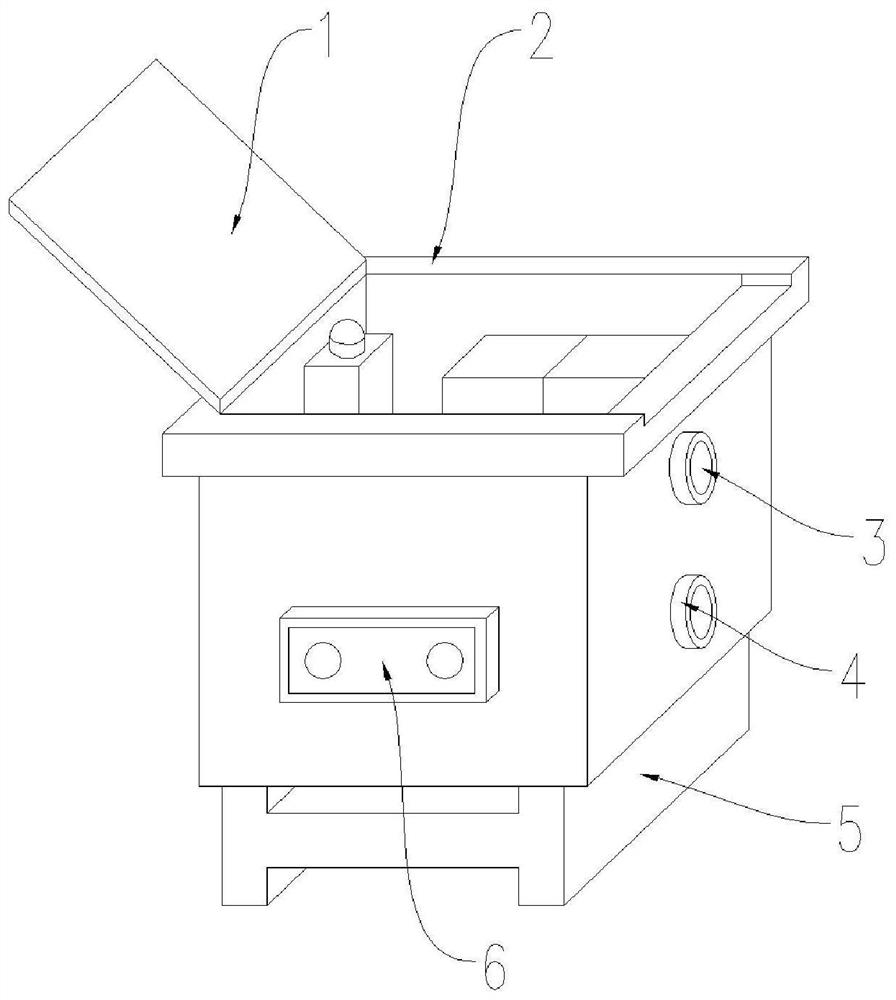

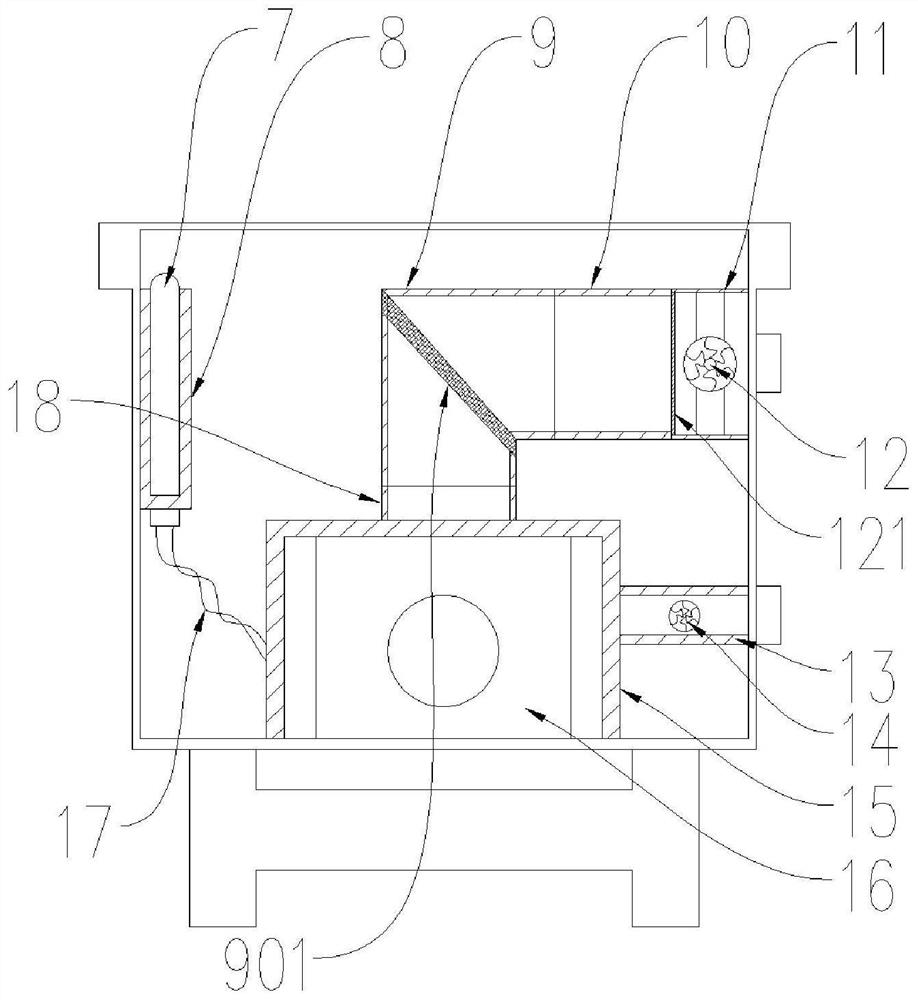

[0024] Example 1, such as figure 1 , figure 2 Shown:

[0025] A high-pressure ozone generator device, comprising a protective shell 2 and a controller 6, a flip door 1 is arranged on the top of the protective shell 2, and a gap is opened on the top side of the protective shell 2, which is convenient to use the flip door 1 to open. The bottom end of shell 2 is provided with step 5, and its height is greater than 1.2m, and inner protective box 15 is set at the inner bottom end of protective shell 2, and a high-pressure ozone generator 16 is installed inside inner protective box 15 simultaneously (using common FL-820N), one side of the inner protective box 15 is provided with an air outlet structure with an air outlet pipe 13 and a negative pressure fan I14, and the air outlet pipe 13 is connected to the air outlet 4, and the air outlet 4 is exposed to the protective shell 2, which is used to discharge ozone for disinfection disinfect;

[0026] The top of the inner protection bo...

Embodiment 2

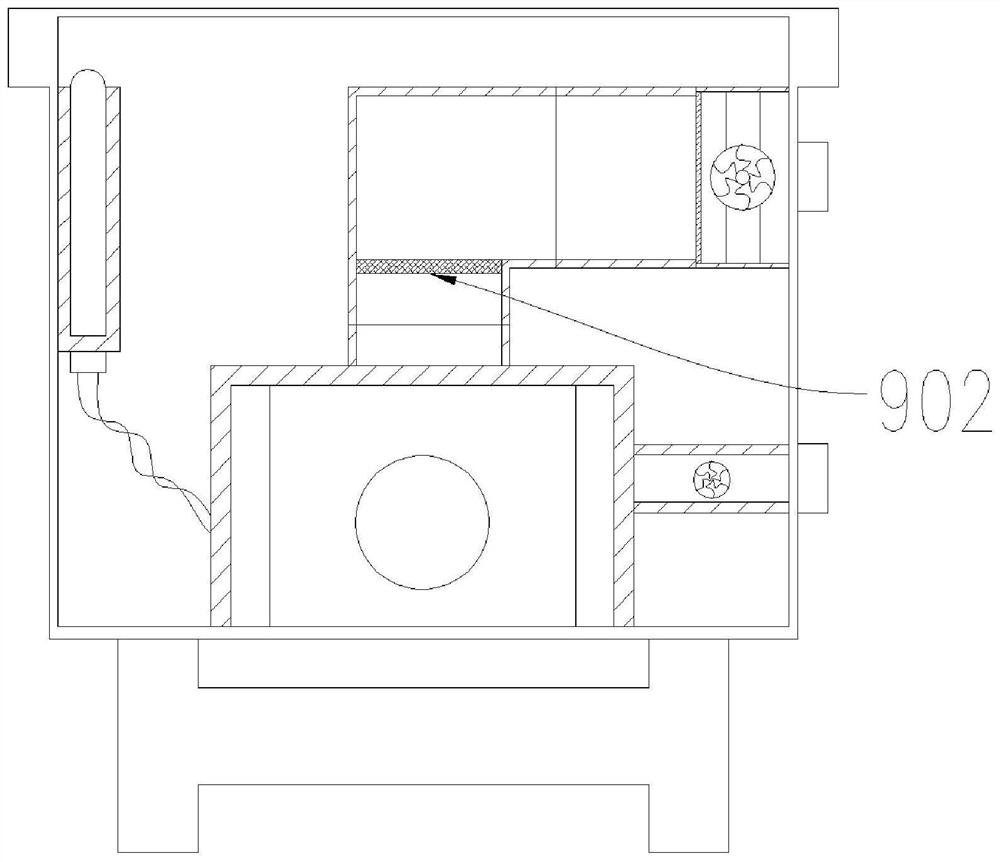

[0028] Example 2, such as figure 1 , image 3 Shown:

[0029] Compared with Example 1, Example 2 changed the activated carbon mesh plate I901 and replaced it with the horizontally arranged activated carbon mesh plate II902 to reduce the area of filtration treatment, which is more cost-effective, but the treatment effect is not as good as that of Example 1.

[0030] Principle of use: Those skilled in the art can program the controller 6 (using the common Siemens S7-200 in the market), so that it can control the components of the device;

[0031] Connect the external pipeline to the air inlet 3, start the negative pressure fan II 12 to extract air, and the air passes through the intake processing pipe 11, the intake pipe 10, and the filter structure 9 in turn, and then enters the high-pressure ozone generator 16, and then it is prepared as ozone and discharged , ozone can temporarily stay in the inner protective box 15, and will not be emitted outwards, so as to avoid rapid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com