A rapid preparation of nb 3 al superconductor method

A superconducting and fast technology, applied in the field of materials, can solve the problems of low superconducting transition temperature, low critical current density, and difficulty in preparation, and achieve high superconducting transition temperature, high critical current density, and good grain connectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

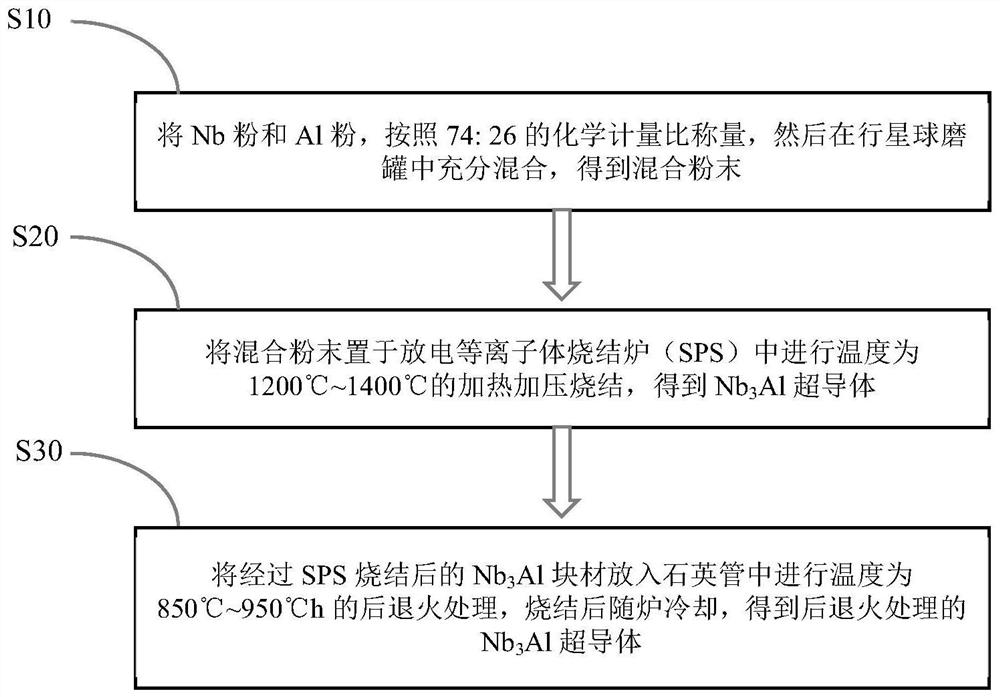

[0037] see figure 1 , the Nb provided by the present invention 3 The preparation method of Al superconductor comprises the following steps:

[0038] Step S10, the Nb powder and the Al powder are weighed according to the stoichiometric ratio of 74:26, and then fully mixed in a planetary ball mill to obtain a mixed powder;

[0039] In step S20, the mixed powder is placed in a discharge plasma sintering furnace for heating and pressure sintering at a temperature of 1200°C to 1400°C to obtain Nb 3 Al superconductor;

[0040] Step S30, the Nb sintered by SPS 3 The Al superconductor was put into a quartz tube for post-annealing treatment at a temperature of 850°C to 950°C and a time of 1.8 to 2.2 hours. After sintering, it was cooled in the furnace to obtain post-annealed Nb 3 Al superconductor.

[0041] In the step S10, in the glove box, the Nb powder and the Al powder are weighed according to the stoichiometric ratio of 74:26, and then put into a ball mill jar, and then fully...

Embodiment 1

[0046]Under the protection of argon, Nb powder with a particle size of 10.5 μm and a purity of 99.95% and Al powder with a particle size of 325 mesh and a purity of >99.7% were weighed according to the stoichiometric ratio of 74:26, and then milled in a planetary ball mill. Fully mixed in the tank, the ball milling speed is 300 PRM, the ball milling time is 30 min, and the ball-to-material ratio is 10:1 to obtain mixed powder.

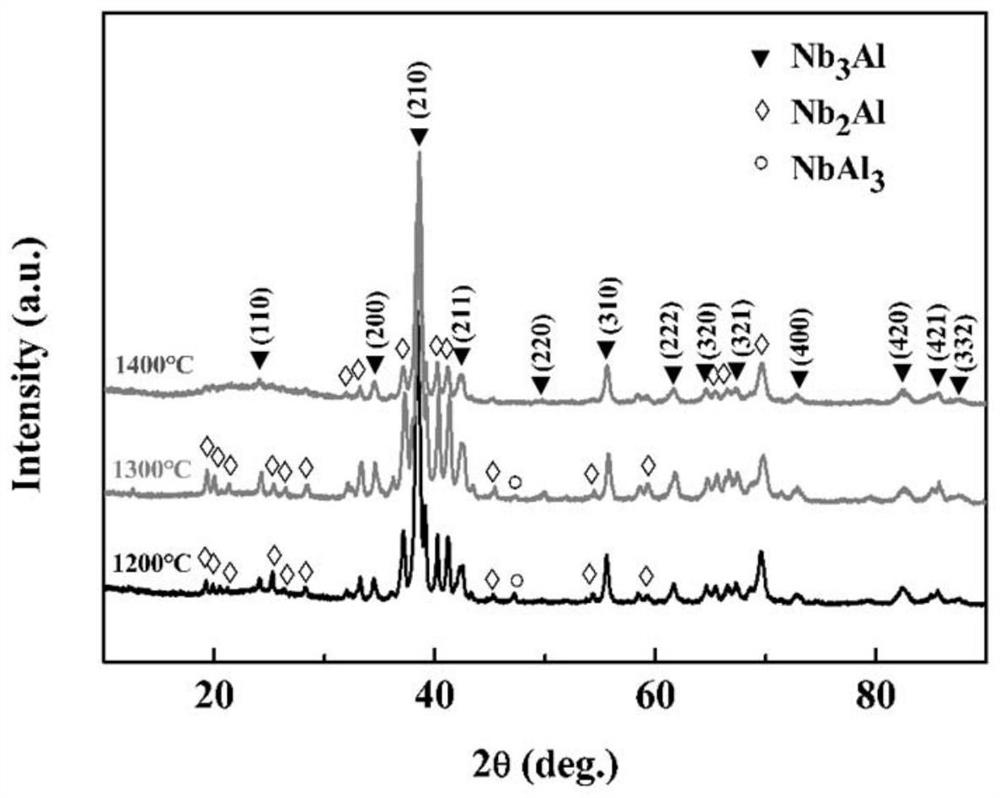

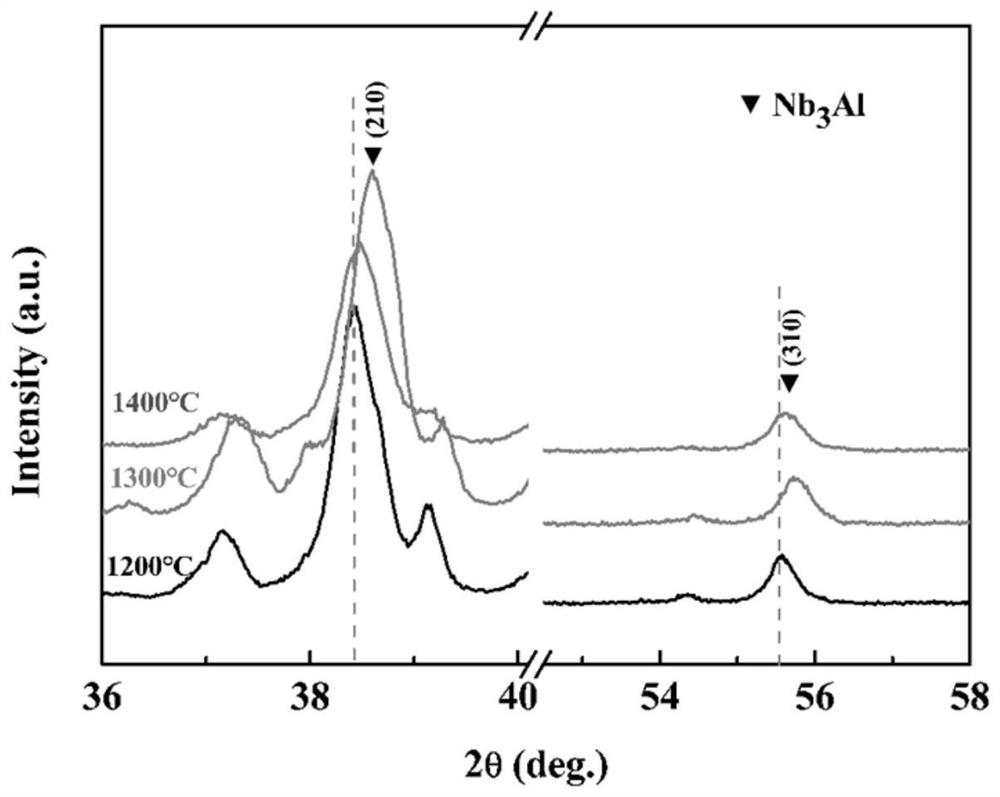

[0047] The mixed powder was placed in a spark plasma sintering furnace (SPS) to maintain a vacuum of 2.5×10 -2 Pa, the pressure is 25Mpa, the sintering temperature is 1200°C, the heating rate is 50°C / min, and the holding time is 5min to obtain Nb 3 Al superconductor.

Embodiment 2

[0049] Under the protection of argon, Nb powder with a particle size of 10.5μm and a purity of 99.95% and Al powder with a particle size of -325 mesh and a purity of >99.7% were weighed according to the stoichiometric ratio of 74:26, and then placed on the planet Mix thoroughly in a ball milling tank, the ball milling speed is 300 PRM, the ball milling time is 30 min, and the ball-to-material ratio is 10:1 to obtain mixed powder.

[0050] The mixed powder was placed in a spark plasma sintering furnace (SPS) to maintain a vacuum of 2.5×10 -2 Pa, the pressure is 25Mpa, the sintering temperature is 1300°C, the heating rate is 50°C / min, and the holding time is 5min to obtain Nb 3 Al superconductor.

[0051] The method of Example 2 is basically the same as that of Example 1, the difference is that the sintering temperature of SPS is 1300°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com