Railway box girder transverse moving and falling device and dismantling construction method

A technology of box girder and lateral movement, which is applied in bridges, bridge maintenance, bridge reinforcement, etc. It can solve the problems that the old beams cannot be removed and the new beams can be rebuilt, so as to reduce the risk of high-altitude operations, high demolition safety, and low construction costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

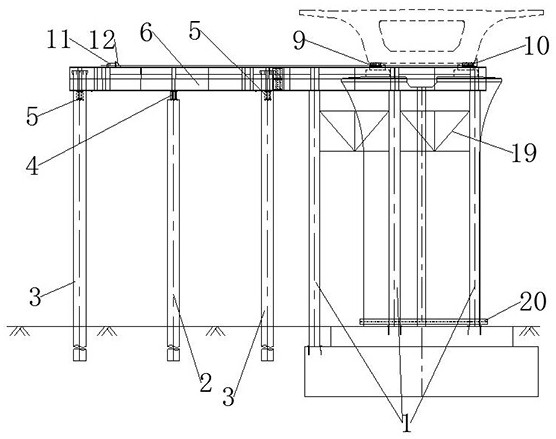

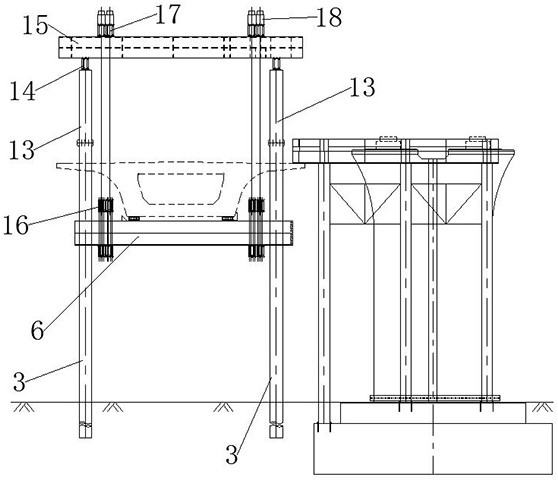

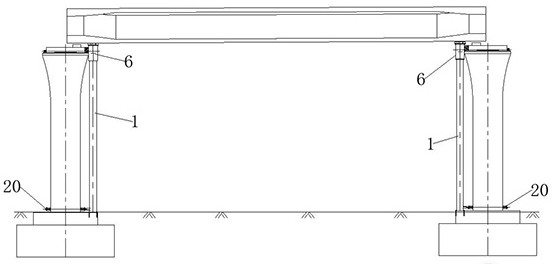

[0039] The present invention will be further described below in conjunction with the accompanying drawings.

[0040] A railway box girder traversing and falling device according to an embodiment of the present invention includes a traversing support and a falling support.

[0041] Specifically, the traversing support includes a steel pipe pile group and a slideway assembly. There are two groups of steel pipe pile groups, which are respectively arranged on the sides of two piers. The steel pipe pile group includes a first steel pipe pile 1 , a second steel pipe pile 2 , a third steel pipe pile 3 , a pile top longitudinal beam 4 and a first pile top distribution beam 5 . The first steel pipe pile 1, the second steel pipe pile 2 and the third steel pipe pile 3 are distributed at intervals along the transverse extension direction of the box girder. The first steel pipe pile 1 is a single row of steel pipe piles, and the first steel pipe pile 1 has three and are located below the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com