A building wall structure

A technology for building walls and houses, which is applied to building components, building structures, buildings, etc., can solve the problems of reducing performance, wasting building materials, and easy loosening, and achieves improving performance, reducing limitations, and stabilizing good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

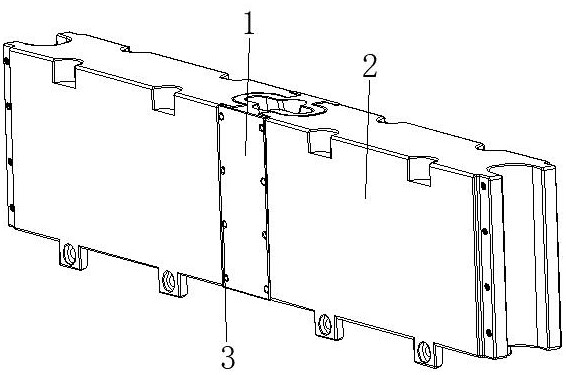

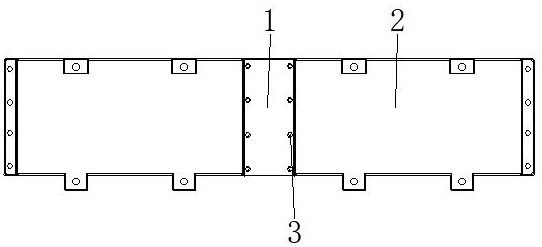

[0032] see Figure 1-6 , the present invention provides a technical solution: a building wall structure, comprising a connecting device 1, a wall panel device 2, and a fixing bolt 3, the wall panel device 2 is matched and connected to the two sides corresponding to the surface end of the connecting device 1, The fixing bolt 3 is screwed on the surface of the connecting device 1 at the position corresponding to the end of the surface of the wall panel device 2;

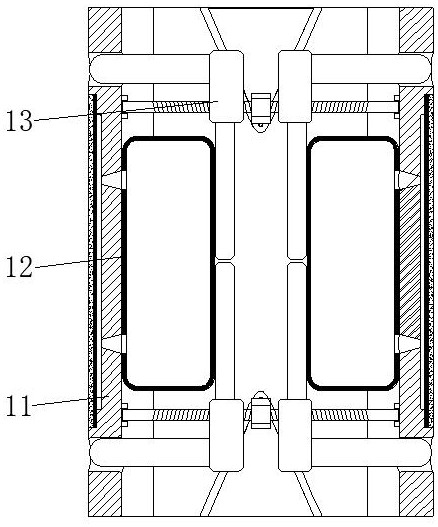

[0033] The connecting device 1 is provided with a base device 11, an elastic airbag 12, and a locking device 13. The surface end of the base device 11 is connected with the end of the wall panel device 2. The elastic airbag 12 is arranged on the inner wall of the base device 11. The locking device 13 is arranged inside the base device 11 and close to the position of the elastic airbag 12, the whole wall can be quickly spliced into any size, easy to disassemble, save time and effort, strong adaptability, reduce limita...

Embodiment example 2

[0035] The connecting device 1 is provided with a base device 11, an elastic airbag 12, and a locking device 13. The surface end of the base device 11 is connected with the end of the wall panel device 2. The elastic airbag 12 is arranged on the inner wall of the base device 11. The locking device 13 is arranged inside the base device 11 and is close to the position of the elastic airbag 12;

[0036] The base device 11 is provided with a connecting base 111 , a fan-shaped gap 112 , an air cavity 113 , an elastic expansion layer 114 , and an anti-skid layer 115 . The elastic expansion layer 114 is arranged on the surface of the connection base 111 and at the position of the air cavity 113, and the anti-skid layer 115 is arranged on the surface of the elastic expansion layer 114. When the pressure plate 135 on the locking device 13 is in the connecting block When the 133 moves to both sides, pressure is applied to the elastic air bag 12. At this time, the compressed air inside t...

Embodiment example 3

[0039] The wall panel device 2 is provided with a wall panel body 21 , a limit pin 22 , a pin groove 23 and an internal thread hole 24 , the limit pin 22 is arranged at the bottom of the wall panel body 21 and is located on the surface, and the pin groove 23 is opened in the wall panel body. On the top of the surface of 21 , the internal threaded hole 24 is opened inside the wall panel main body 21 and is located at the position of the limiting pin 22 and the pin groove 23 .

[0040] The limit pins 22 and the pin grooves 23 are located on the same line. The limit pins 22 are evenly distributed at the bottom of the wall panel body 21, and the pin grooves 23 are evenly distributed on the top surface of the wall panel body 21. The limit pins 22 and the pin grooves 23 are used. It is matched and fixed through the inner threaded hole 24, and then assembled with the connecting device 1 and the wall panel device 2, which can be continuously spliced, and then spliced and disassembled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com