Artificial agglomerated stone manufacturing pretreatment method utilizing optimized aggregate gradation interface performance

A technology of artificial stone and interface performance, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve the impact of lack of quantitative, scientific, intelligent, artificial stone product performance and cost , low production efficiency and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

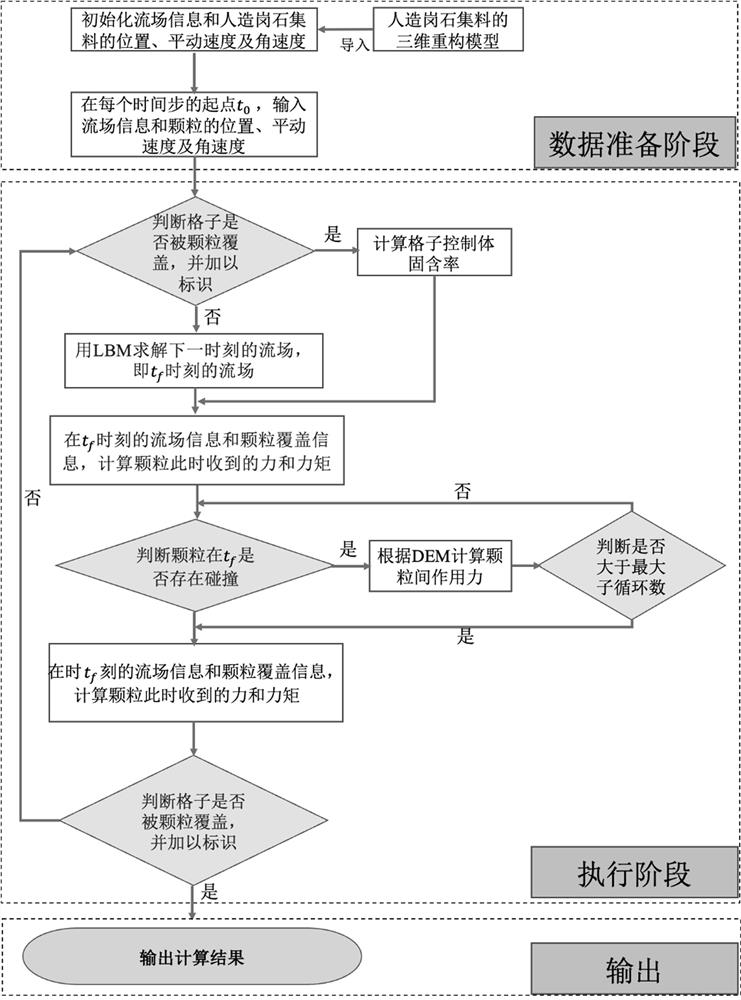

[0030] A method for pre-manufacturing artificial granite utilizing optimized aggregate gradation interface performance, comprising the following steps:

[0031] (1) Establishment of artificial granite aggregate characterization and selection decision-making data set;

[0032] ① Artificial granite material selection pre-treatment process: comprehensively analyze its chemical composition, three-dimensional microscopic appearance, particle size and gradation composition, and obtain artificial granite aggregate characterization data;

[0033] ②Through experiments and simulations to study the accumulation theory of granite aggregates, characterize and classify them, obtain artificial granite aggregates with stable structure and uniform particle size distribution, and classify them into aggregate information datasets for machine learning according to label types;

[0034] (2) Acquisition of powder gradation and material internal parameters and optimization of machine learning data s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com