Intelligent manufacturing method of artificial granite based on control of lbm-dem aggregate gradation interface characteristics

A technology of artificial granite and interface characteristics, applied in the field of artificial granite manufacturing, can solve the problems of long trial production process cycle, lack of artificial granite quantitative, scientific, intelligent, affecting the overall mechanical properties of artificial granite products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] An artificial granite intelligent manufacturing method based on the regulation of LBM-DEM aggregate gradation interface characteristics, comprising:

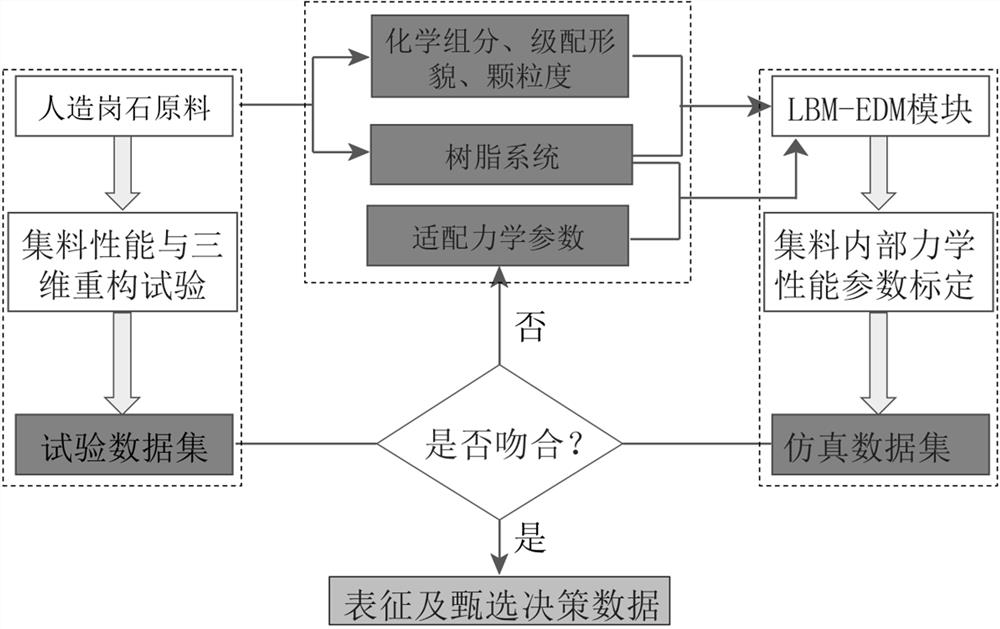

[0042] (1) Establishment of artificial granite aggregate characterization and selection decision data sets (such as figure 1 shown);

[0043] ①Using characterization instruments to systematically analyze the physicochemical properties of artificial granite aggregates to obtain characterization data of artificial granite aggregates; characterization instruments include scanning electron microscopy (SEM), X-ray diffraction (XRD), thermogravimetric analyzer (TGA), Fourier Transform Infrared Spectrometer (FTIR);

[0044] ②Using high-precision 3D scanning equipment to scan aggregates with different particle sizes, and use 3D modeling software to complete 3D reconstruction;

[0045]③Finally, quantitatively select and classify artificial granite aggregates by particle size type and gradation according to chemical composition, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com