Welding copper column for PCB

A copper column and column technology, applied in the direction of electrical connection of printed components, printed circuit components, electrical components, etc., can solve problems such as retention, tin cannot be completely dispersed, affecting welding quality, etc., and achieve the effect of enhancing stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below, combined with figure 1 to attach Figure 6 As well as specific embodiments, the present invention will be further described. It should be noted that, on the premise of not conflicting, the various embodiments or technical features described below can be combined arbitrarily to form new embodiments.

[0028] Below, combined with figure 1 to attach Figure 6 As well as specific embodiments, the present invention will be further described. It should be noted that, on the premise of not conflicting, the various embodiments or technical features described below can be combined arbitrarily to form new embodiments.

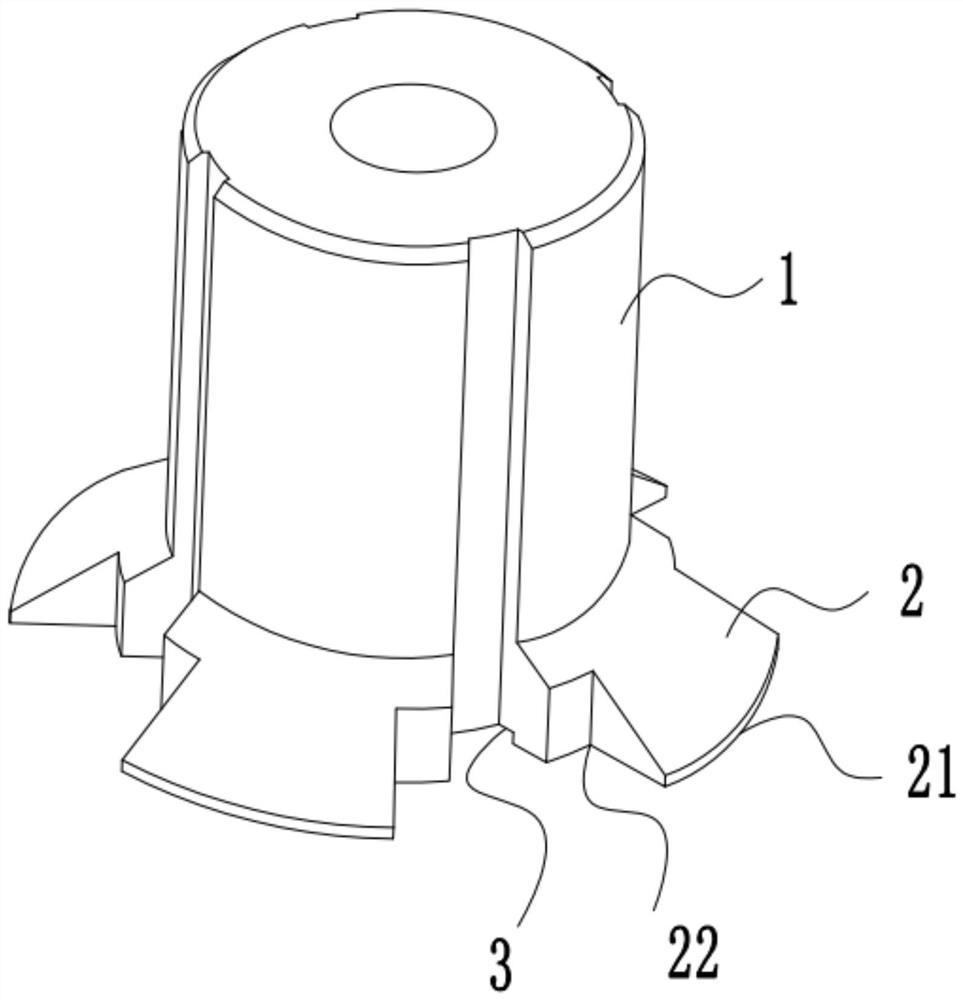

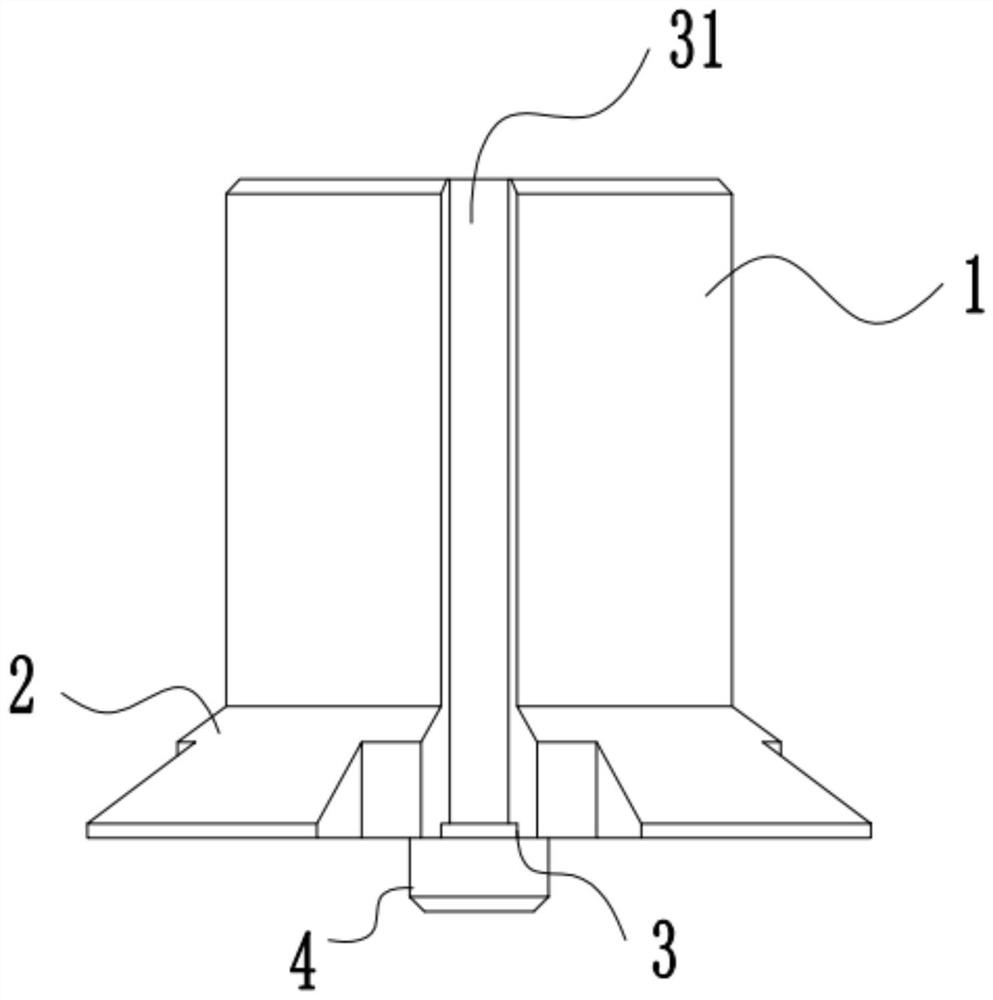

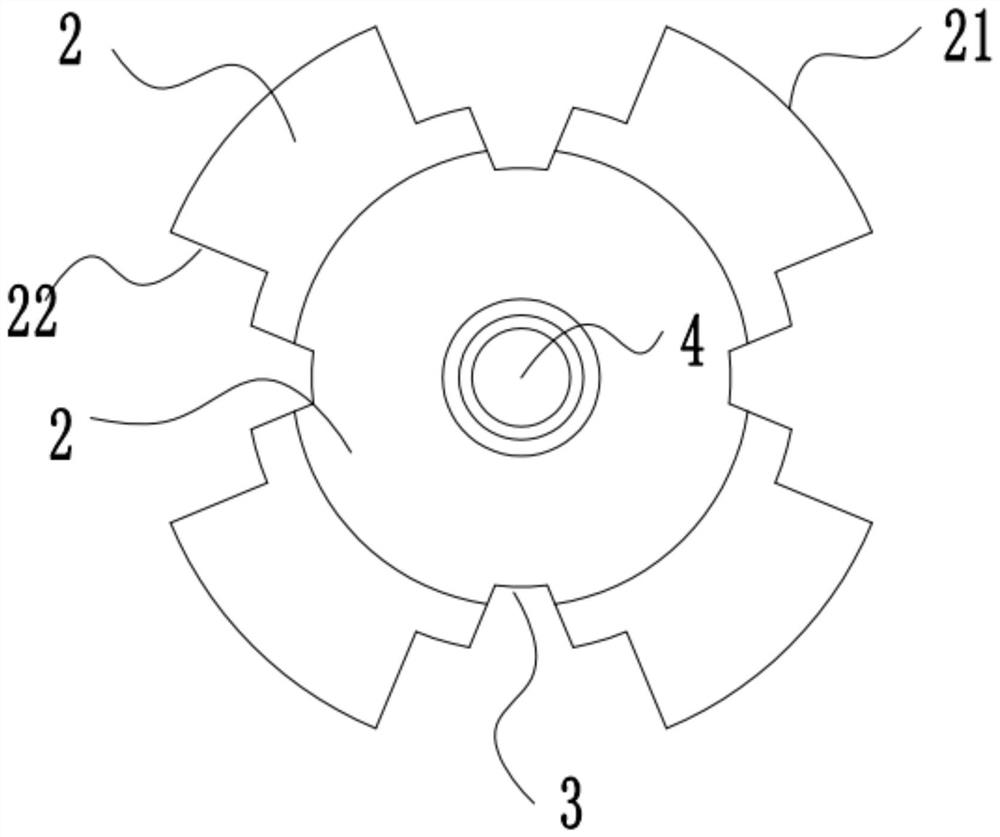

[0029] The embodiment of the present invention provides a soldering copper column for a PCB board, such as figure 1 and figure 2 As shown, it includes a cylinder 1 and a chassis part 2, the cylinder 1 is a cylinder 1, and the end of the cylinder 1 and the PCB board is the bonding end 11, and the chassis part 2 is arranged on the cylinder 1. Fitting en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com