Electronic atomization device and heating assembly and heating body thereof

A technology of heating components and heating bodies, which is applied to tobacco and other directions, can solve the problems of short service life of heating materials, concentration of atomized media, and easy to produce burnt smell, so as to increase the number of practical applications, improve anti-fatigue life, and avoid the concentration of atomized media. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

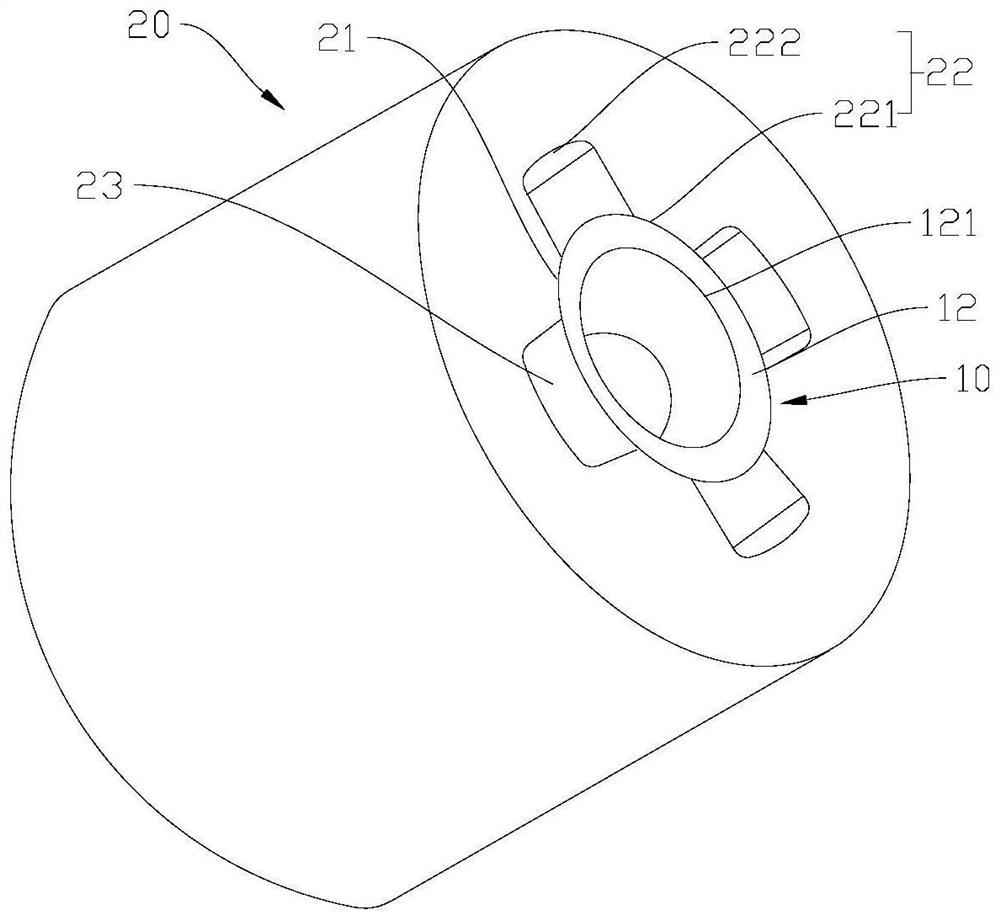

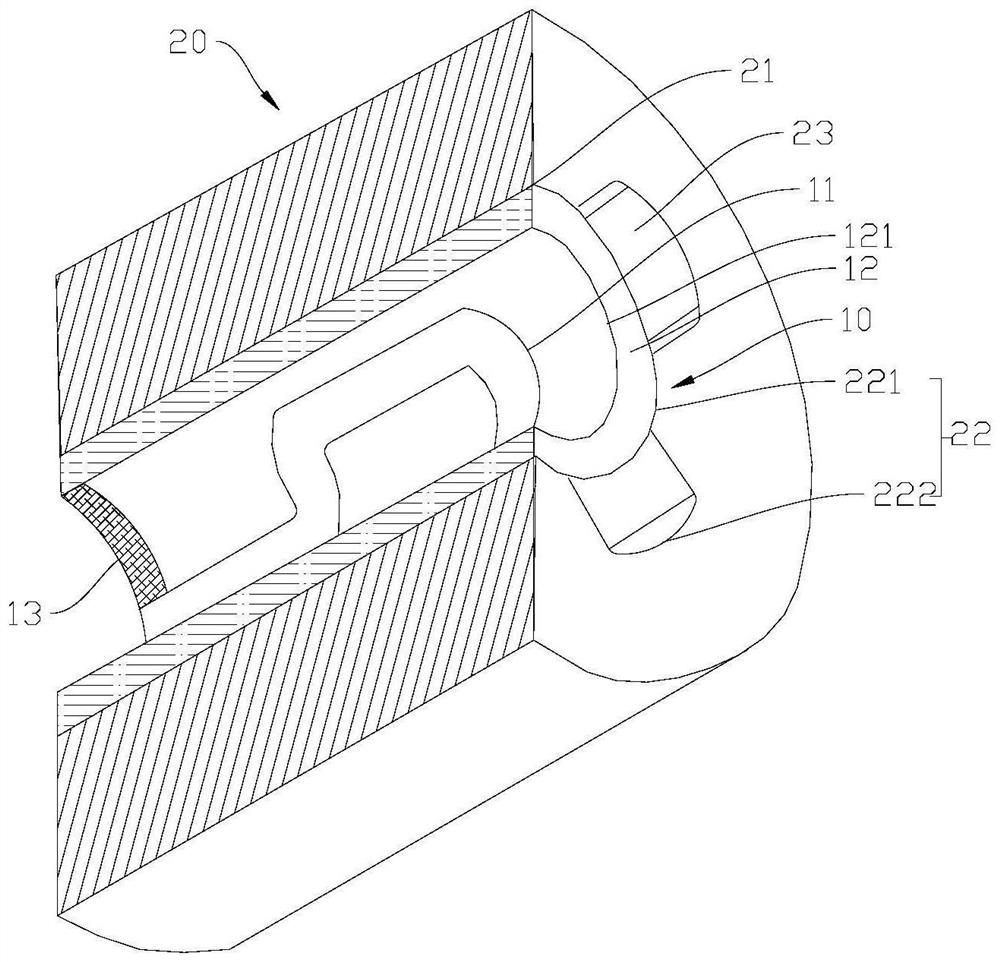

[0032] figure 1 and figure 2 Some preferred embodiments of the electronic atomization device of the present invention are shown. The electronic atomization device can be used to heat and atomize the liquid atomizing medium to generate atomized gas for users to inhale. In some embodiments, the electronic atomization device has the advantages of simple structure, high atomization efficiency, good atomization taste, long service life, low manufacturing cost and easy implementation.

[0033] Such as figure 1 and figure 2 As shown, further, in this embodiment, the electronic atomization device may include an atomizing case, a heating component, and a power supply component. atomizing medium. The power supply componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com