Silicon nitride-comprising nanomaterial and preparation method and use thereof

A technology of nanomaterials and silicon nitride, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of large waste of heat energy, poor material structure strength, high production cost, etc., and achieve a good cycle The effect of service life, structural strain relief, and production time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0051] Specific embodiment 1 (see Figure 1-25 ):

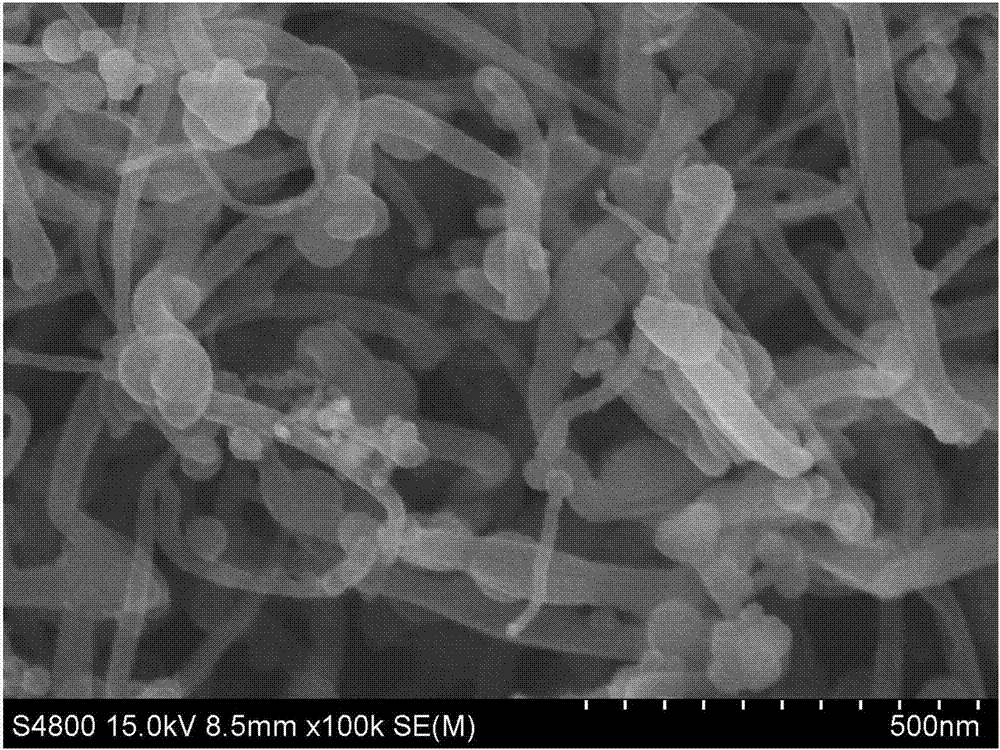

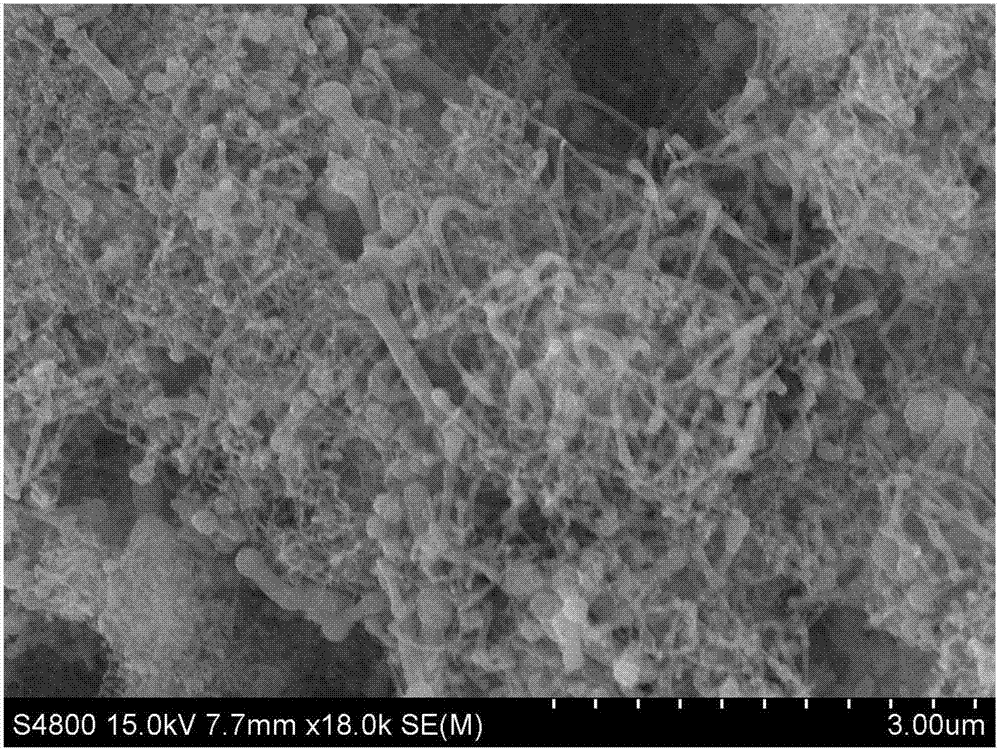

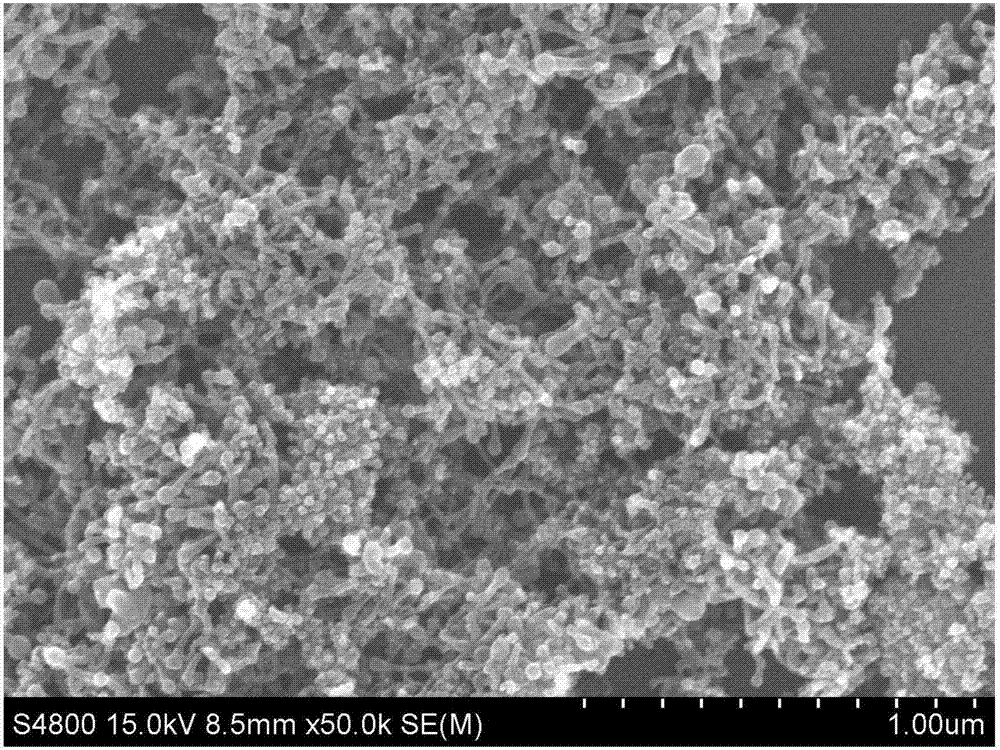

[0052] The first step: Weigh the cotton-like elemental silicon nanowire clusters (such as 1-8) provided by Taizhou Jinbo Qidao Nano Material Technology Co., Ltd., enter the vacuum tube furnace, and replace the air in the vacuum tube furnace with nitrogen to reach When the oxygen content is at 600PPm, start heating the furnace to 1150°C at a rate of 12°C / min, keep the temperature constant for 5 hours, then raise the temperature to 1190°C at a rate of 1°C / min, keep the temperature constant for 1 hour, then cool down naturally to 350°C, absorb The surface of the cotton-like elemental silicon nanowire cluster in the furnace penetrates deeply into the material covered with the silicon nitride layer (as shown in Figure 9-16).

[0053] The second step: Weigh 20 grams of high-temperature petroleum asphalt and 100 grams of the material coated with silicon nitride layer in step 1 and mix them into a dry ball mill for uniform dispersio...

example 2

[0056] Example 2, such as Figure 1-24 , Figure 26 Shown:

[0057] All others refer to Example 1, the difference is: the second time described in step 1 is heated up to 1190 ° C, and the temperature is kept at a constant temperature for 3 hours. The button battery made according to this example has a charging specific capacity of 2326mAh / g for the first time. The discharge specific capacity is 2156mAh / g, the second charge specific capacity is 2115mAh / g, the second discharge specific capacity is 2009mAh / g, the first Coulombic efficiency reaches 92.5%, and the capacity can reach 1816.5mAh / g after 100 cycles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com