High-pressure nozzle structure capable of increasing foaming times

A high-pressure nozzle and foaming multiple technology, applied in fire rescue and other fields, can solve the problems of poor fire extinguishing effect of fire extinguishing equipment, inability to spray fire for a long distance, and poor foaming quality, so as to ensure smoothness, good coverage effect, and even bubble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

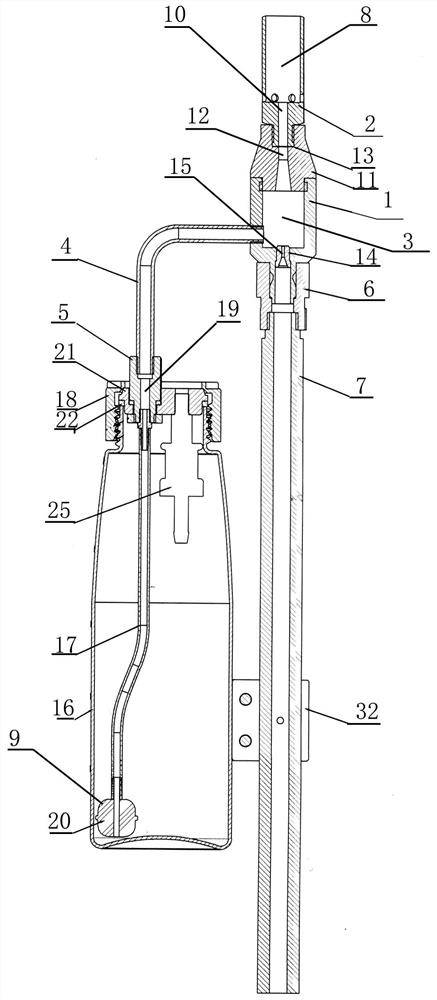

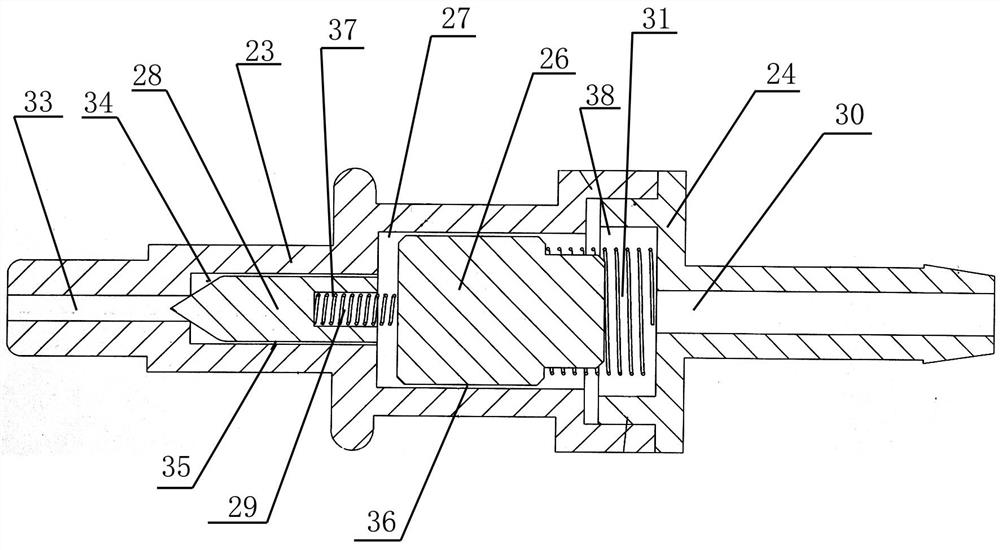

[0014] exist figure 1 and figure 2Among them, the present invention provides a structure of a high-pressure nozzle that increases the foaming ratio, which mainly includes a nozzle body 1 and an extended foaming tube 2, a mixing chamber 3 is arranged axially inside the nozzle body 1, and a nozzle body 1 The side of the foam suction pipe 4 is provided, and one end of the foam suction pipe 4 communicates with the foam bottle assembly through the suction pipe joint 5, and the other end of the foam suction pipe 4 extends into the interior of the nozzle body 1 and communicates with the mixing chamber 3. One end is provided with a quick connector 6, the nozzle body 1 is connected to the spray handle 7 of the water flow through the quick connector 6, the spray handle 7 is connected to the mixing chamber 3, and the other end of the nozzle body 1 is connected to one end of the extended foam tube 2 There is a detachable connection between them. A foam generating chamber 10 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com