Mechanical part cleaning device for mechanical design and manufacturing and cleaning method thereof

A cleaning device and technology for mechanical parts, applied in the field of cleaning of mechanical parts, can solve the problems of difficult cleaning of mechanical parts, collision damage, incomplete cleaning of mechanical parts, etc., and achieve the effect of improving cleanliness and convenient loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

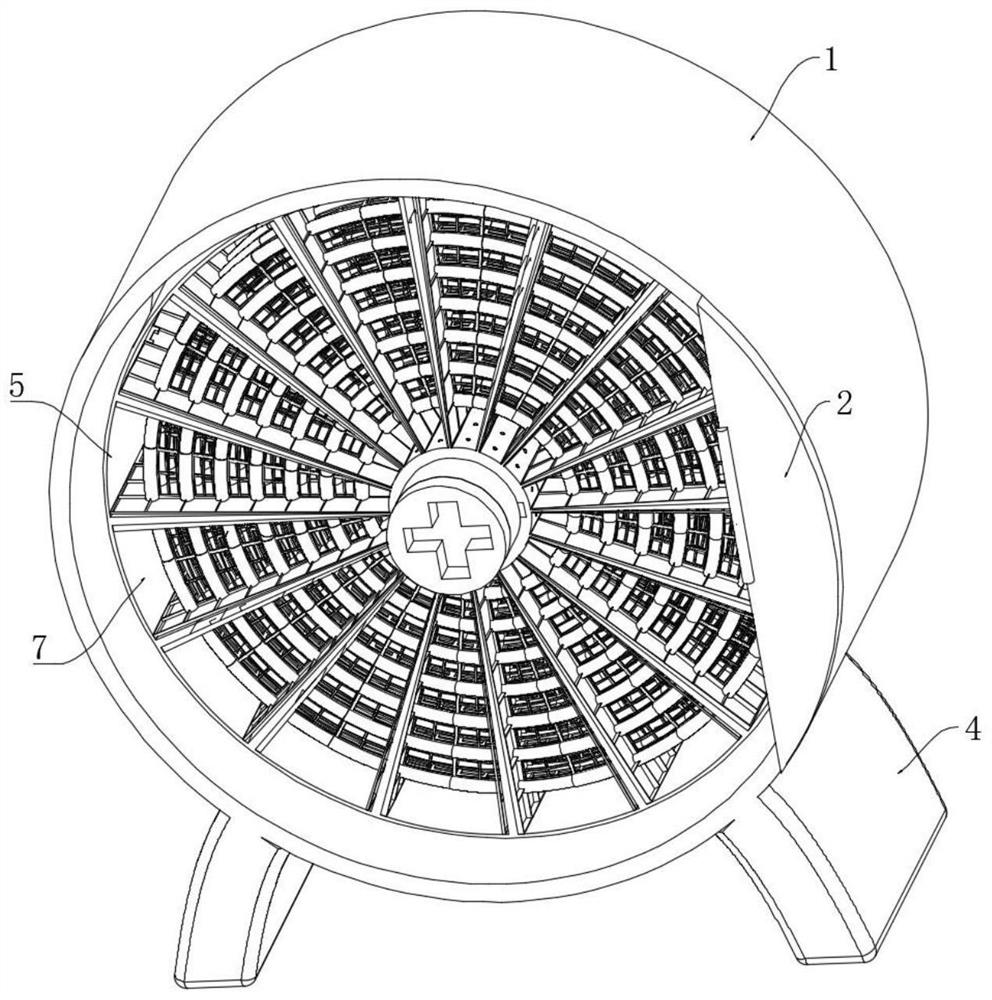

[0060]As an embodiment of the present invention, the tumbling cleaning device includes several first porous partitions 8, and all the first porous partitions 8 are fixed in an annular array inside the rotating cylinder 5, and the first porous partitions 8 will rotate the rotating cylinder. The interior of 5 is divided into a plurality of compartments 7, the open ends of compartments 7 face the airtight door 3, and one side of all the first porous partitions 8 is fixed with a fixed porous plate 9, and the support bone intersection of the fixed porous plate 9 All are fixed with a first arc tube 10, and one end of all the first arc tubes 10 facing away from the fixed perforated plate 9 is provided with a second arc tube 14, and all the second arc tubes 14 are facing away from the first arc One end of the shaped tube 10 is jointly fixed with an overturned perforated plate 12, and the side of the overturned perforated plate 12 facing away from the fixed perforated plate 9 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com