Preparation method of crossed corrugated interface metal composite plate

A metal composite plate and cross-corrugated technology, applied in metal rolling and other directions, can solve problems such as easy warping, low yield, and low bonding strength, and achieve the effects of descaling guarantee, good bonding effect, and improved bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

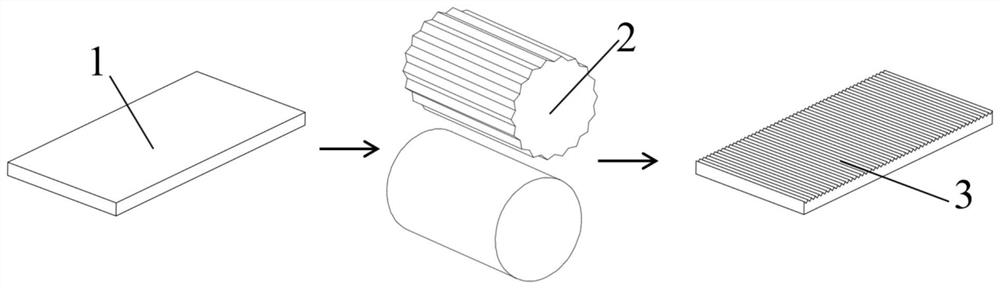

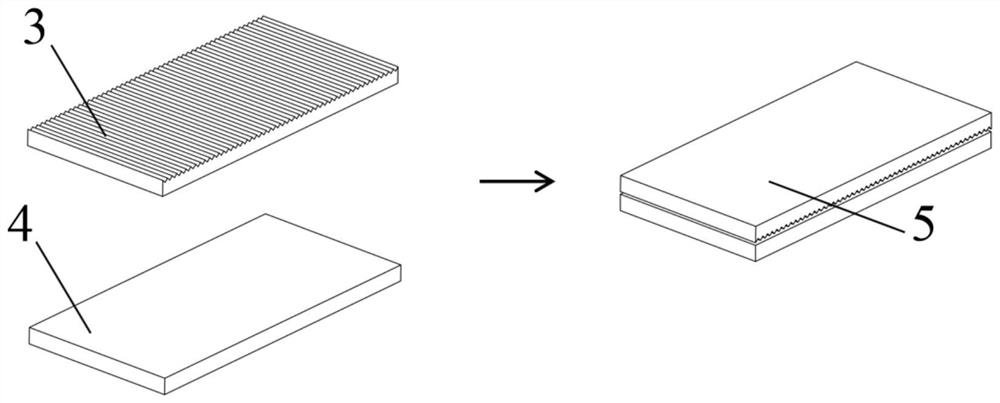

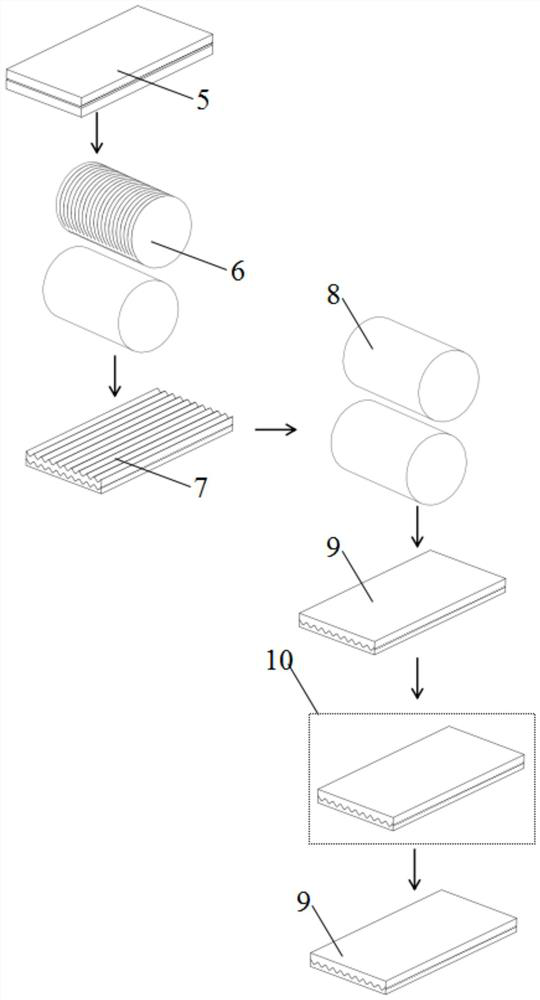

[0049] according to Figure 1-6 , preparing a copper / aluminum composite board, comprising the following steps:

[0050] S1, such as figure 1 As shown, the T1 copper plate with relatively large deformation resistance is selected as the double plate 1, the size is 100mm×50mm×3mm, and the T1 copper plate is sent to the wave flat rolling mill a 2 for the first rolling with a reduction rate of 10%. The upper roll of the rolling mill is a one-way corrugated roll with transverse corrugations on the surface, the lower roll is a flat roll, and the cross-section of the transverse corrugations is triangular. Corrugated (the first corrugated surface), the lower surface is a plane, corrugated copper plate with a thickness of 2.70mm;

[0051] S2. Select a 1060 aluminum plate with relatively small deformation resistance as the substrate 4, with a size of 100mm×50mm×3mm. Use a wire brush grinder to derust and roughen the surface of the corrugated copper plate and aluminum plate; use a high-...

Embodiment 2

[0058] according to Figure 1-6 , preparing a titanium / aluminum composite plate, comprising the following steps:

[0059] S1, such as figure 1 As shown, the TA1 titanium plate with relatively large deformation resistance is selected as the compound plate 1, the size is 100mm×50mm×5mm, and the TA1 titanium plate is sent to the wave flat rolling mill a 2 for the first rolling with a reduction rate of 10%. The upper roll of the corrugated flat rolling mill is a one-way corrugated roll with transverse corrugations on the surface, the lower roll is a flat roll, and the cross-section of the transverse corrugations is triangular. It is a corrugated titanium plate with transverse corrugation (the first corrugated surface), the lower surface is a plane, and the thickness is 4.5mm;

[0060] S2. Select a 1060 aluminum plate with relatively small deformation resistance as the substrate 4, with a size of 100mm×50mm×5mm. Use a wire brush grinder to derust and roughen the surface of the co...

Embodiment 3

[0067] The preparation of a steel / copper / steel composite plate comprises the following steps:

[0068] S1. Select the Q235 steel plate with relatively large deformation resistance as the double plate 1, the size is 100mm×50mm×5mm, and send the Q235 steel plate to the wave flat rolling mill a 2 for the first rolling with a reduction rate of 10%. The upper roller is a one-way corrugated roller with transverse corrugations on the surface, the lower roller is a flat roller, the cross-section of the transverse corrugations is triangular, the corrugation depth is 0.5mm, and the corrugation period is 1mm. After rolling, the upper surface is transverse corrugations. (the first corrugated surface), the lower surface is a flat corrugated steel plate with a thickness of 4.5mm;

[0069] S2. Select the T2 copper plate with relatively small deformation resistance as the substrate, with a size of 100mm×50mm×10mm, and use a wire brush grinder to derust and roughen the surface of the corrugate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com