Double-sided sand blasting device capable of uniformly covering and used for organic glass production

A technology of plexiglass and uniform coverage, which is applied in the direction of used abrasive processing devices, abrasive jetting machine tools, manufacturing tools, etc., and can solve problems such as the inability to sandblast both sides at the same time, the sandblasting sand, and the reuse of sieve slag. , to achieve the effect of increasing the reuse rate, saving cost, and uniform sandblasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

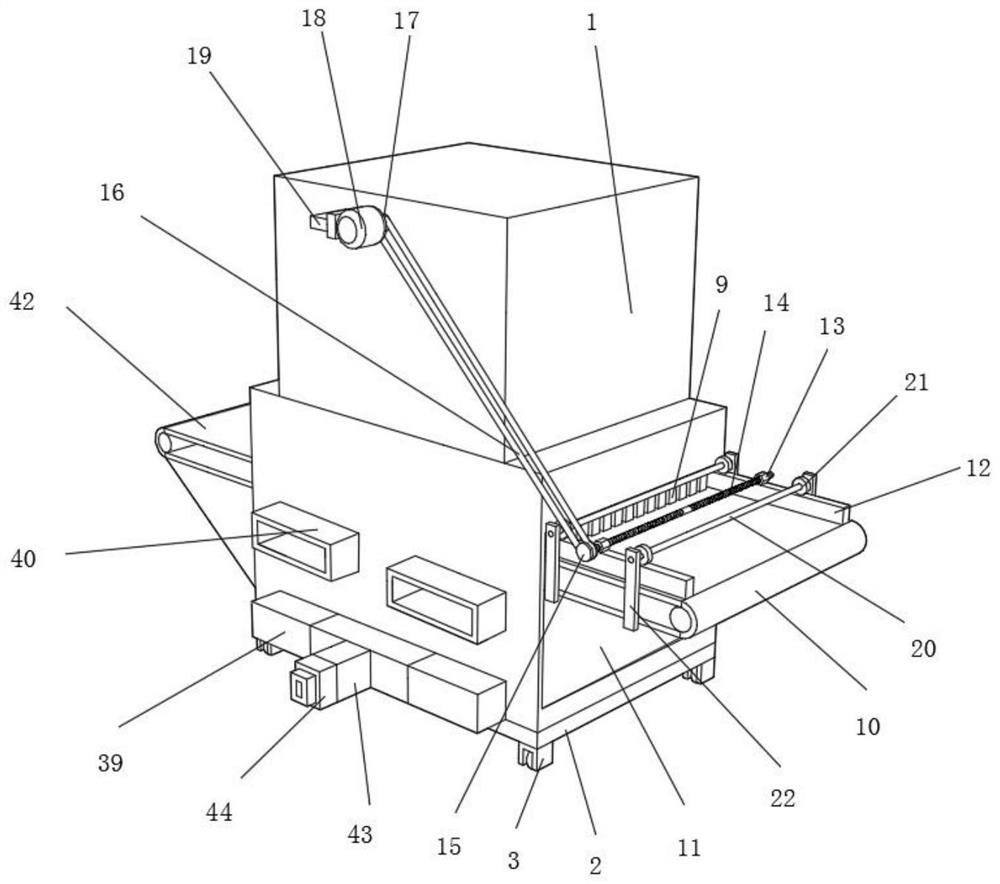

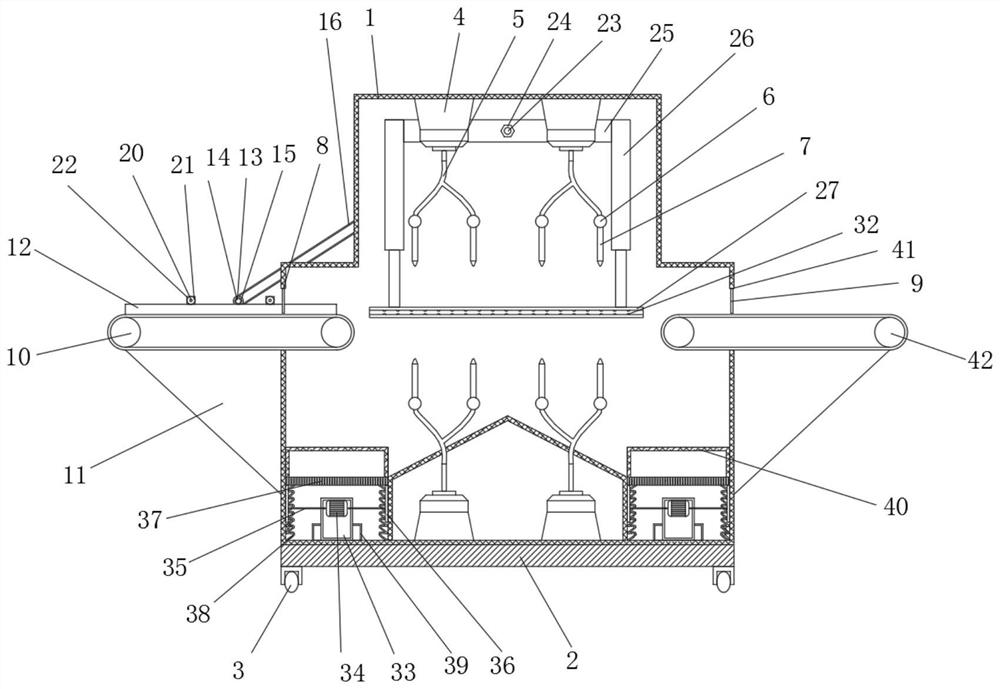

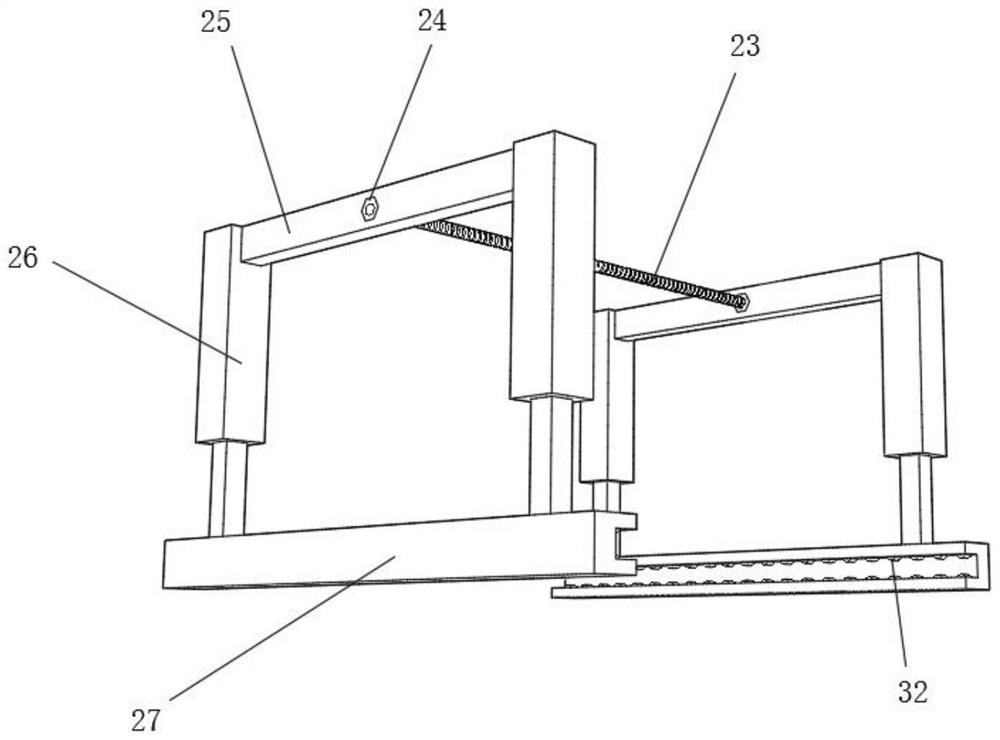

[0030] Such as Figure 1-6As shown, the embodiment of the present invention provides a double-sided sandblasting device for the production of plexiglass that can be evenly covered, including a box body 1, the left middle part of the box body 1 is provided with a feed port 8, and the inner lower part of the feed port 8 The first conveyor belt 10 is provided, and the front and rear sides of the upper end of the first conveyor belt 10 are slidingly connected with a push plate 12, and the middle part of the upper end of the push plate 12 is fixedly connected with a first threaded sleeve 13, and the middle part of the first threaded sleeve 13 is screwed on the The front and rear ends of the first two-way threaded rod 14 are fixedly connected with the first pulley 15 at the rear end of the first two-way threaded rod 14, and the first pulley 15 is connected with the second pulley 17 by the transmission belt 16, and the front side of the second pulley 17 The middle part is fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com