Multi-shaft alternative punching machine for new materials

A punching machine and new material technology, applied in the field of punching machines, can solve the problems of low punching efficiency and low safety, and achieve the effect of improving punching efficiency, improving safety, and facilitating collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

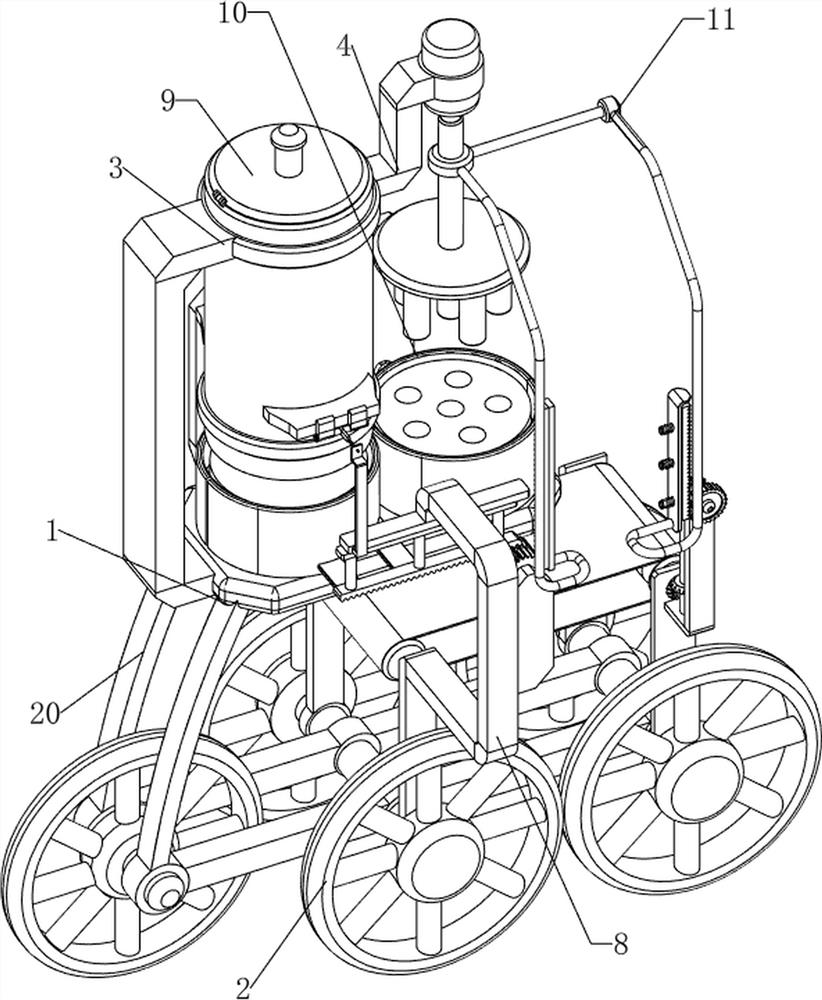

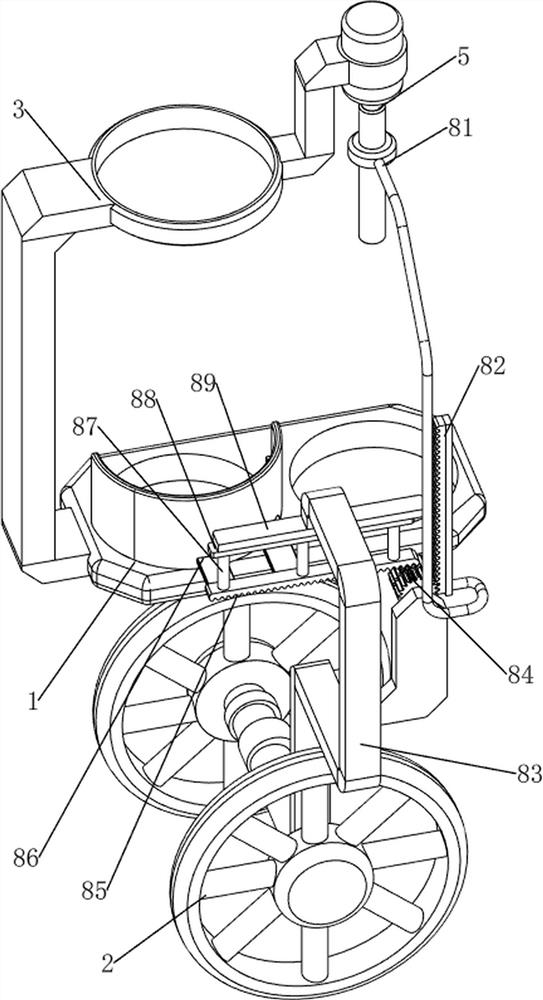

[0026] A new material multi-axis alternate punching machine, such as Figure 1-7 As shown, it includes a first support plate 1, a tire 2, a connecting frame 20, a support frame 3, a first fixed plate 4, a cylinder 5, a second fixed plate 6, a punching rod 7, a transmission mechanism 8, and a blanking mechanism 9 With the clamping mechanism 10, the bottom of the first support plate 1 is connected with a connecting frame 20, and the front and rear sides of the connecting frame 20 are rotatably equipped with tires 2, and the left side of the connecting frame 20 is also rotatably installed with a tire 2, and the left side of the connecting frame 20 Connected with a support frame 3, the upper part of the right side of the support frame 3 is connected with a first fixed plate 4, a cylinder 5 is installed on the first fixed plate 4, a second fixed plate 6 is connected on the telescopic rod of the cylinder 5, and the second fixed plate 6 The bottom is evenly spaced with punching rods ...

Embodiment 2

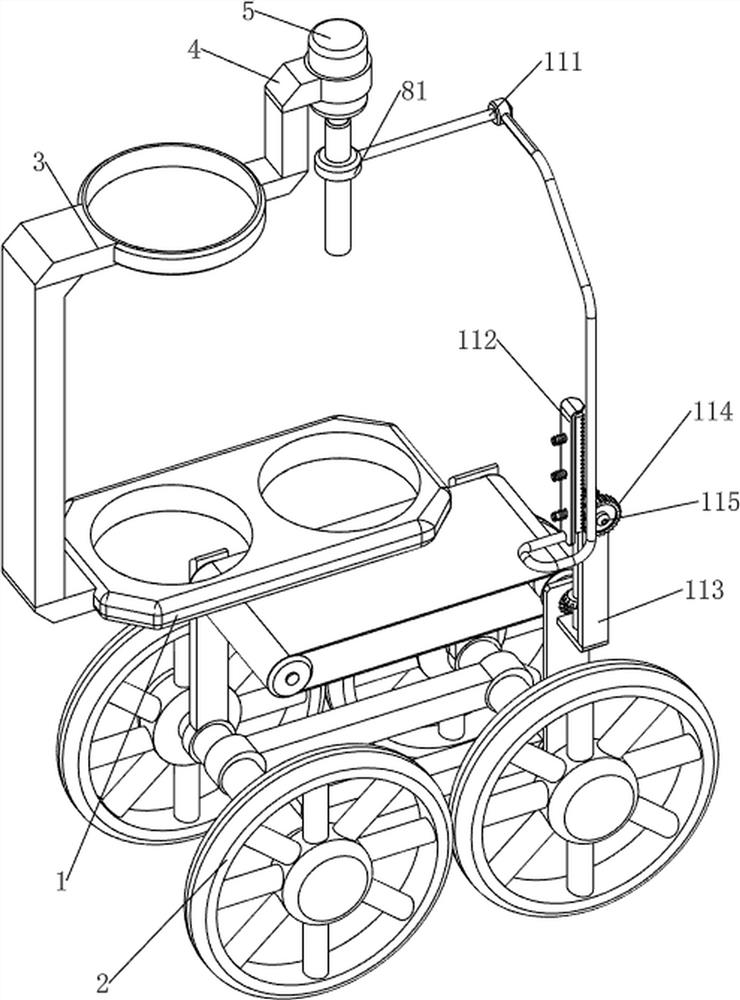

[0032] On the basis of Example 1, such as figure 1 , Figure 8 and Figure 9 As shown, a discharge mechanism 11 is also included, and the discharge mechanism 11 includes a third link 111, a ratchet bar 112, a fifth support plate 113, a ratchet 114, a rotating shaft 115, a second rotating rod 116, the first full bevel gear 117, the third rotating rod 118, roller 119, conveyor belt 1110 and the second full bevel gear 1111, the upper part of the first connecting rod 81 right side is connected with the third connecting rod 111, the third connecting rod 111 bottom is provided with ratchet bar 112, the second A fifth support plate 113 is connected to the right front side of the top of the support plate 1, and the upper part of the fifth support plate 113 is rotatably connected to a rotating shaft 115. A ratchet 114 is installed on the front end of the rotating shaft 115, and the ratchet 114 engages with the ratchet bar 112. The middle part of the fifth support plate 113 The vertic...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap