Novel ink printing process

A technology of ink printing and process, applied in the direction of ink, printing, printing post-processing, etc., can solve the problems of user's health impact, influence on use effect, and poor rendering effect, so as to reduce waste, reduce the risk of damage, and guarantee The effect of print quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

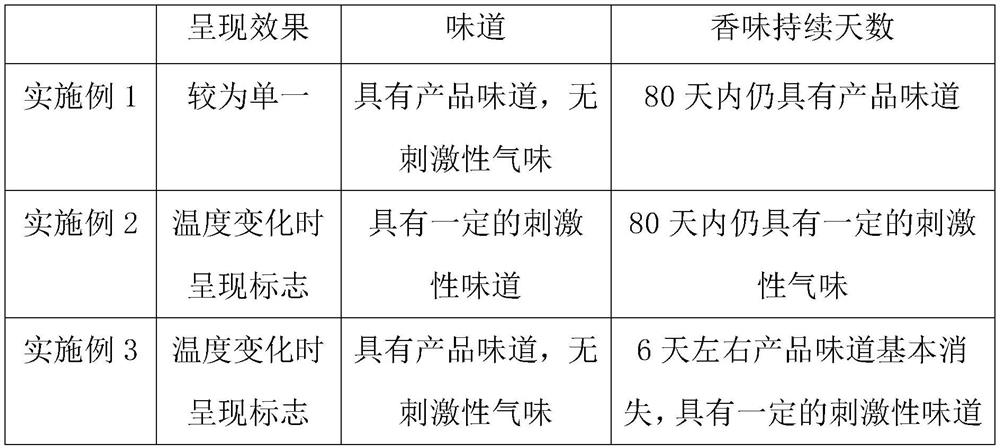

Embodiment 1

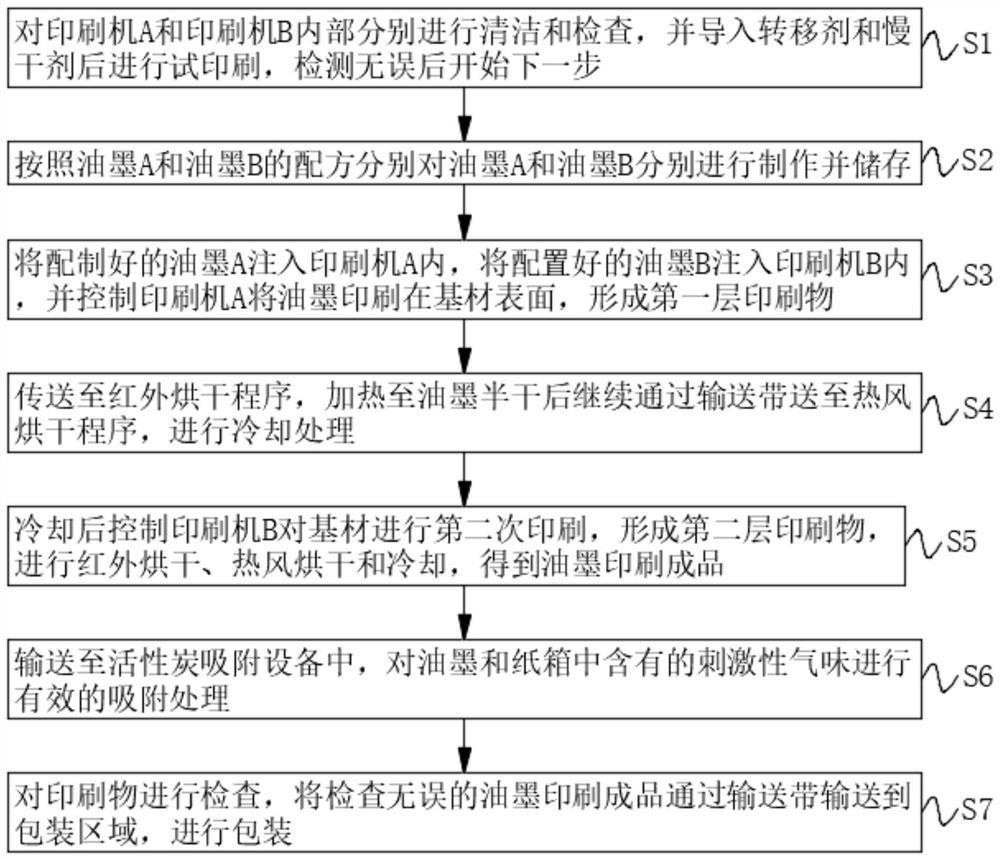

[0029] A novel ink printing process, the novel ink printing process comprises the following steps:

[0030]S1. Clean and check the printing machine A, and introduce transfer agent and slow drying agent into the ink storage box in the equipment, and add a small amount of ink for 5-8 trial printings. After the detection is correct, start the next step. If there is an abnormality , contact personnel for maintenance, and start the next step after the abnormality is fixed.

[0031] S2. Make ink: put 5-20 parts of ethanolamine, 5-25 parts of isopropanol and 10-25 parts of sand powder and polypropylene resin in a mixer, and replenish the raw materials to 100 parts with water, and heat up to 150- After mixing evenly at 200°C, add 6-8 parts of high-temperature-resistant carrier and 0.5-0.6 parts of turkelenone, continue mixing for 5-10 minutes, then add 3-4 parts of propylene glycol, 2-3 parts of geraniol, and 2-3 parts Vanillyl alcohol, 2-3 parts of phenylethyl alcohol and 2-3 parts ...

Embodiment 2

[0045] A novel ink printing process, the novel ink printing process comprises the following steps:

[0046] S1. Clean and inspect the interior of printing machine A and printing machine B respectively, and introduce transfer agent and slow drying agent into the ink storage box in the equipment, and add a small amount of ink for 5-8 trial printings, start after the inspection is correct In the next step, when there is an abnormality, contact the personnel for maintenance, and the next step can only be started after the abnormality is repaired.

[0047] S2. Making the ink: 5-20 parts of ethanolamine, 5-25 parts of isopropanol, 10-25 parts of sand powder and polypropylene resin are placed in a mixer, and the raw materials are replenished to 100 parts by water to obtain ink A, Mix 30-40 parts of resin emulsion, 30-40 parts of temperature-sensitive toner, 3-5 parts of fluorescent powder, 5-8 parts of dispersant, 0.2-0.5 parts of defoamer, 2-3 parts of leveling agent, 1-2 Parts of ...

Embodiment 3

[0059] A novel ink printing process, the novel ink printing process comprises the following steps:

[0060] S1. Clean and inspect the interior of printing machine A and printing machine B respectively, and introduce transfer agent and slow drying agent into the ink storage box in the equipment, and add a small amount of ink for 5-8 trial printings, start after the inspection is correct In the next step, when there is an abnormality, contact the personnel for maintenance, and the next step can only be started after the abnormality is repaired.

[0061] S2. Make ink: put 5-20 parts of ethanolamine, 5-25 parts of isopropanol and 10-25 parts of sand powder and polypropylene resin in a mixer, and replenish the raw materials to 100 parts with water, and heat up to 150- After mixing evenly at 200°C, add 6-8 parts of high-temperature-resistant carrier and 0.5-0.6 parts of turkelenone, continue mixing for 5-10 minutes, then add 3-4 parts of propylene glycol, 2-3 parts of geraniol, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com