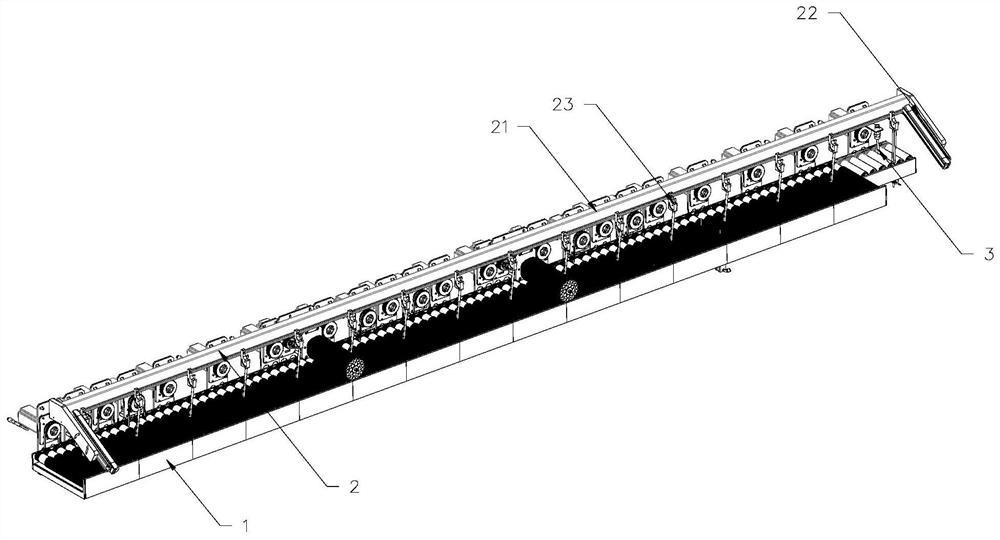

Modular bagged product arranging and conveying device

A conveying device and modular technology, applied in the direction of conveyor control devices, conveyor objects, packaging, etc., can solve the problems of inability to separate soft bags from each other, stop maintenance, delay shipments, etc., to achieve easy diversion, short downtime, The effect of ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

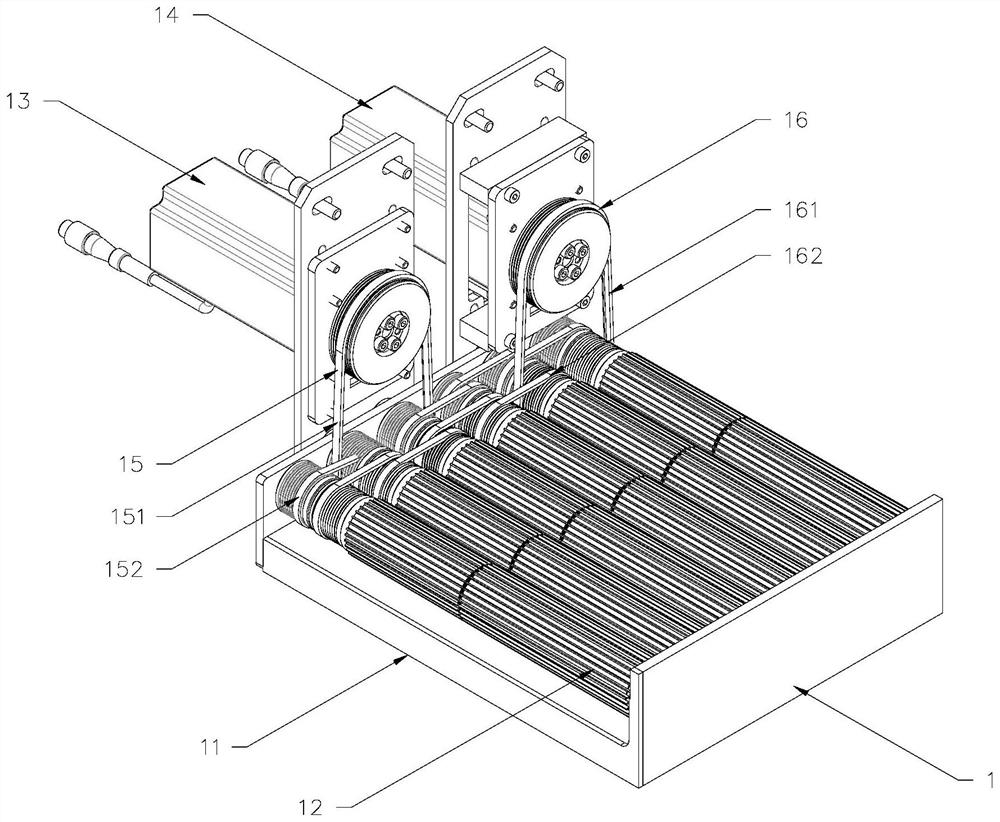

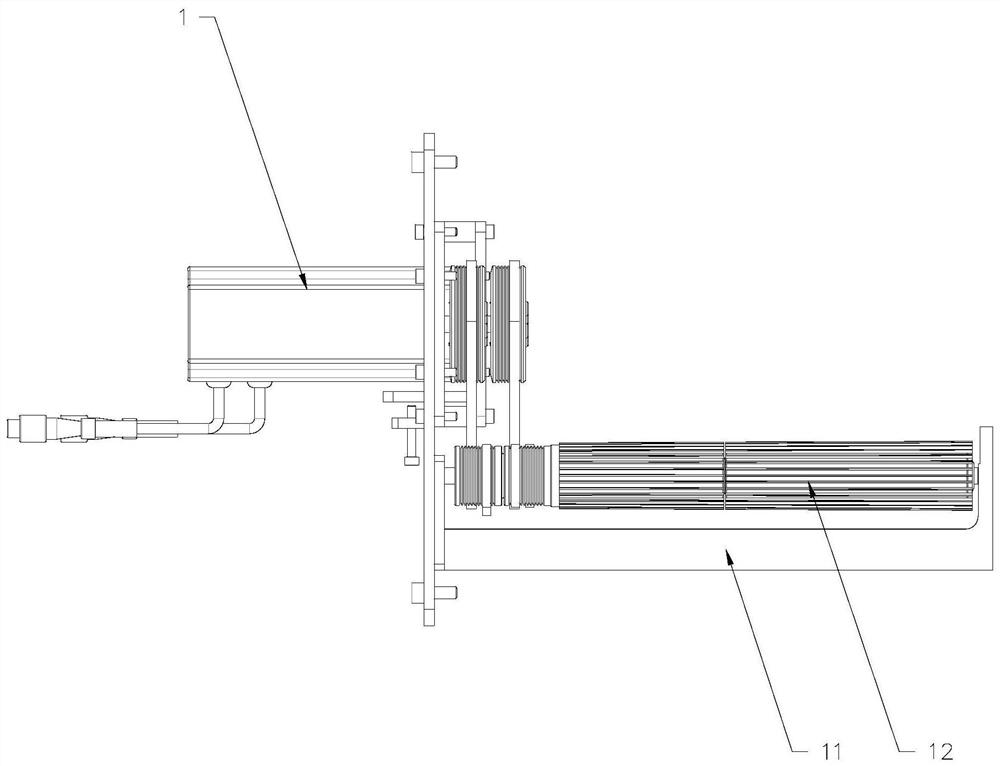

[0024] refer to Figure 1 to Figure 7 , a modular bagged product sorting and conveying device of the present invention includes a dual-power roller mechanism 1, a speed measuring mechanism 2 and a controller. , the second motor 14, the first transmission assembly 15, the second transmission assembly 16 and the controller, a plurality of the rollers 12 are respectively rotatably connected on the cylinder frame 11 and arranged parallel to each other, and the rollers 12 are arranged along the A first barrel section and a second barrel section that can rotate independently without interfering with each other are arranged in the axial direction, and the first motor 13 simultaneously drives the first barrel section of each roller 12 to rotate through the first transmission assembly 15, The second motor 14 simultaneously drives the second cylinder section of each roller 12 to rotate through the second transmission assembly 16, and several of the dual-powered roller mechanisms 1 are d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com