Bidirectional moving type ship loader and ship loading method thereof

A two-way moving, ship loader technology, applied in the direction of conveyor, loading/unloading, conveyor objects, etc., can solve the problems of uneven unloading, side deflection of the hull, etc., to prevent uneven unloading rate, reduce side The effect of flipping risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

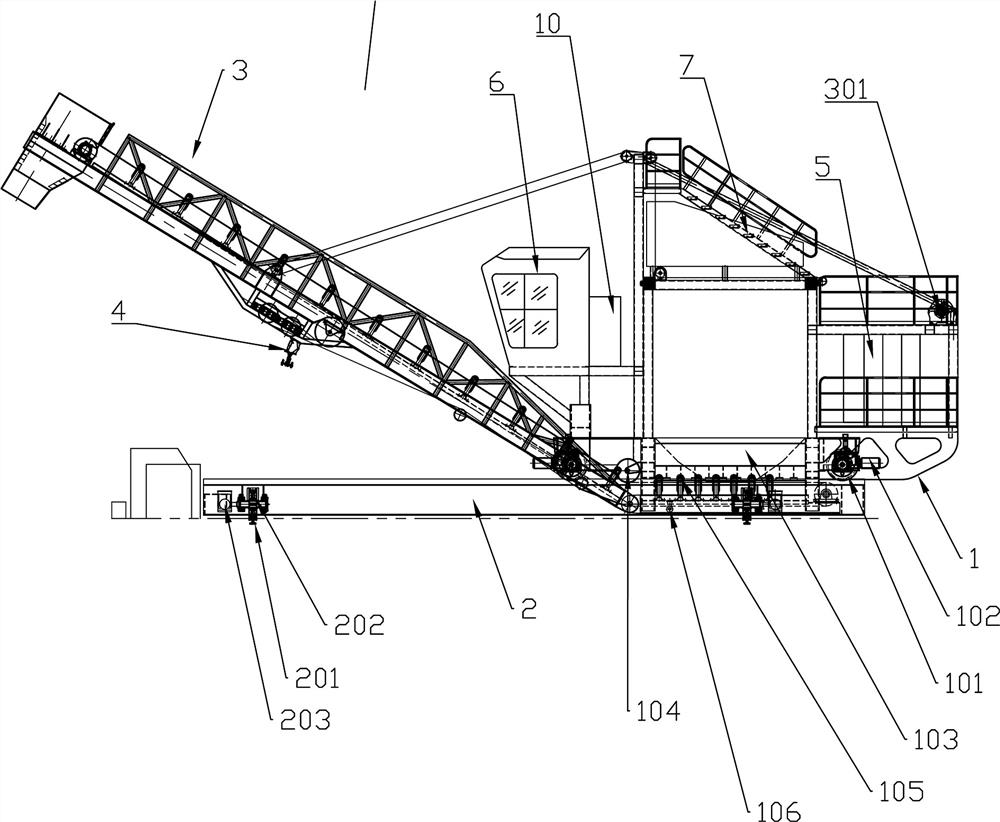

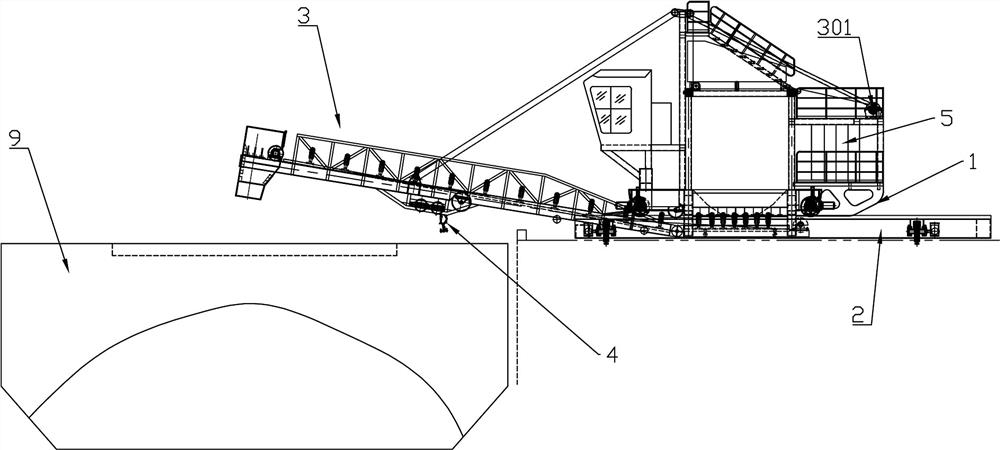

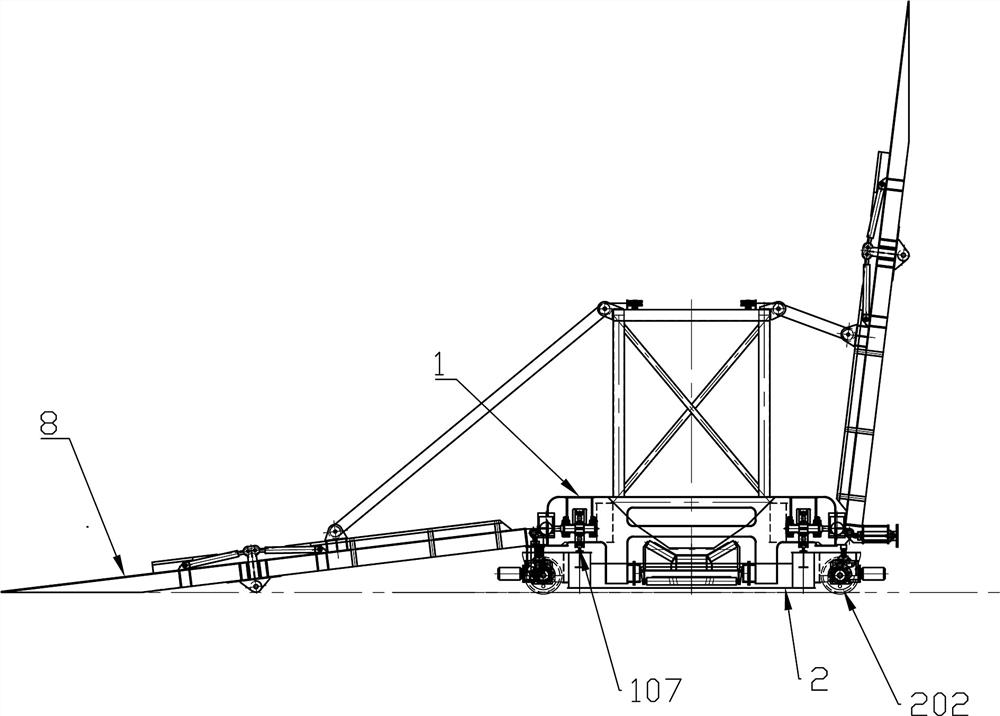

[0039] Such as Figure 1-12 Among them, a two-way mobile ship loader includes a base frame 1 and an underframe 2, one end of the base frame 1 is provided with a rotatable cantilever conveying device 3, the base frame 1 is provided with a feed hopper 103, and the cantilever conveying device 3 is far away from the base One end of the frame 1 is provided with a discharge port 302, and the material is fed by the feed hopper 103 and then conveyed through the cantilever conveying device 3, and then unloaded from the discharge port 302 to the cargo ship 9, and the lower end of the base frame 1 is provided with a plurality of first moving parts. Wheel 101, at least two first guide rails 107 are provided on the upper side of the chassis 2, and the first traveling wheels 101 roll against the first guide rails 107. The lower end of the chassis 2 is provided with a plurality of second traveling wheels 202. Lay at least two parallel second guide rails 201, the second road wheels 202 walk o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com