Automatic egg trolley positioning device in vaccine production process

A technology for automatic positioning and vaccine production, which is applied in transportation, packaging, loading/unloading, etc. It can solve problems that affect production efficiency, cannot take and place egg trays normally, size deviation, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

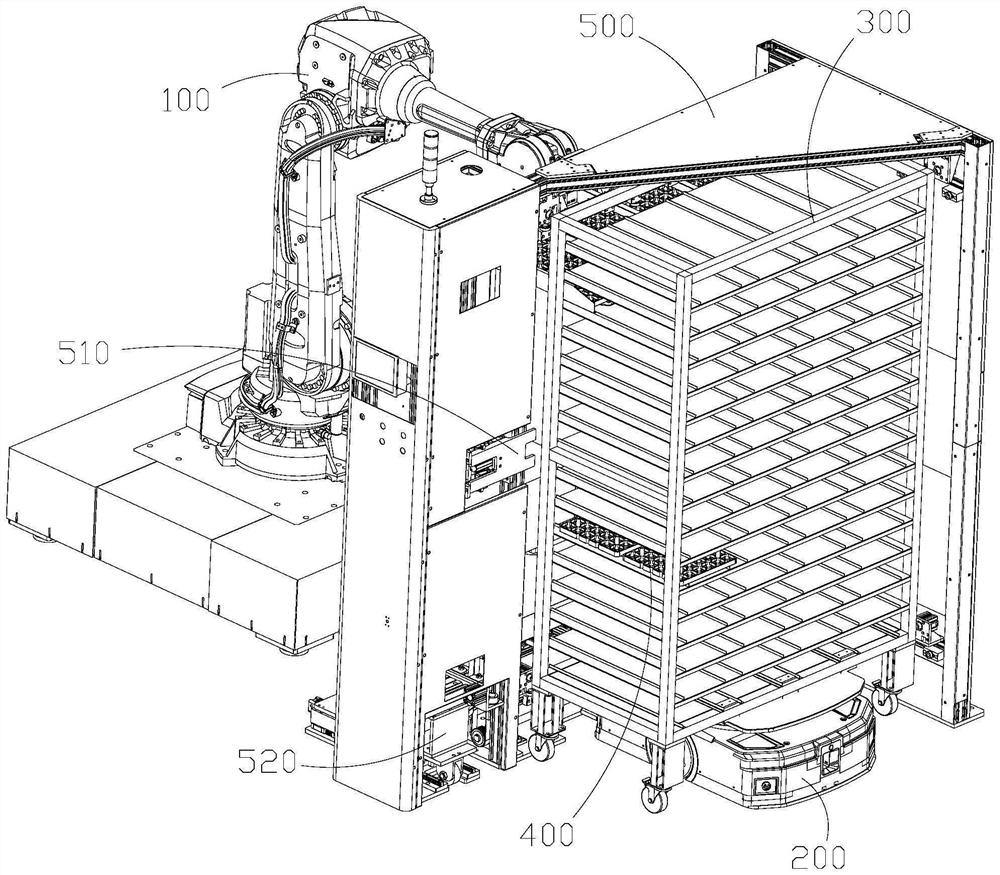

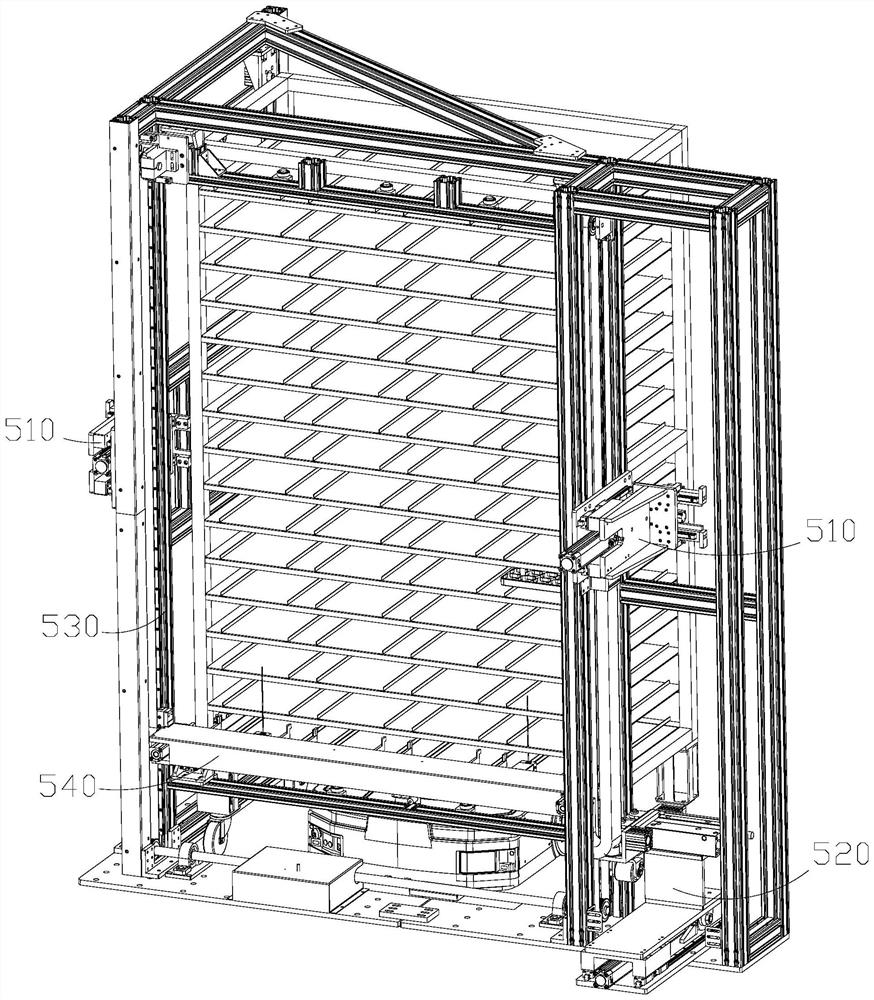

[0037] Such as figure 1 As shown, this embodiment designs an automatic positioning device for egg trolleys in the vaccine production process, including an L-shaped positioning bracket 500 whose long and short sides match those of the egg trolley 300 .

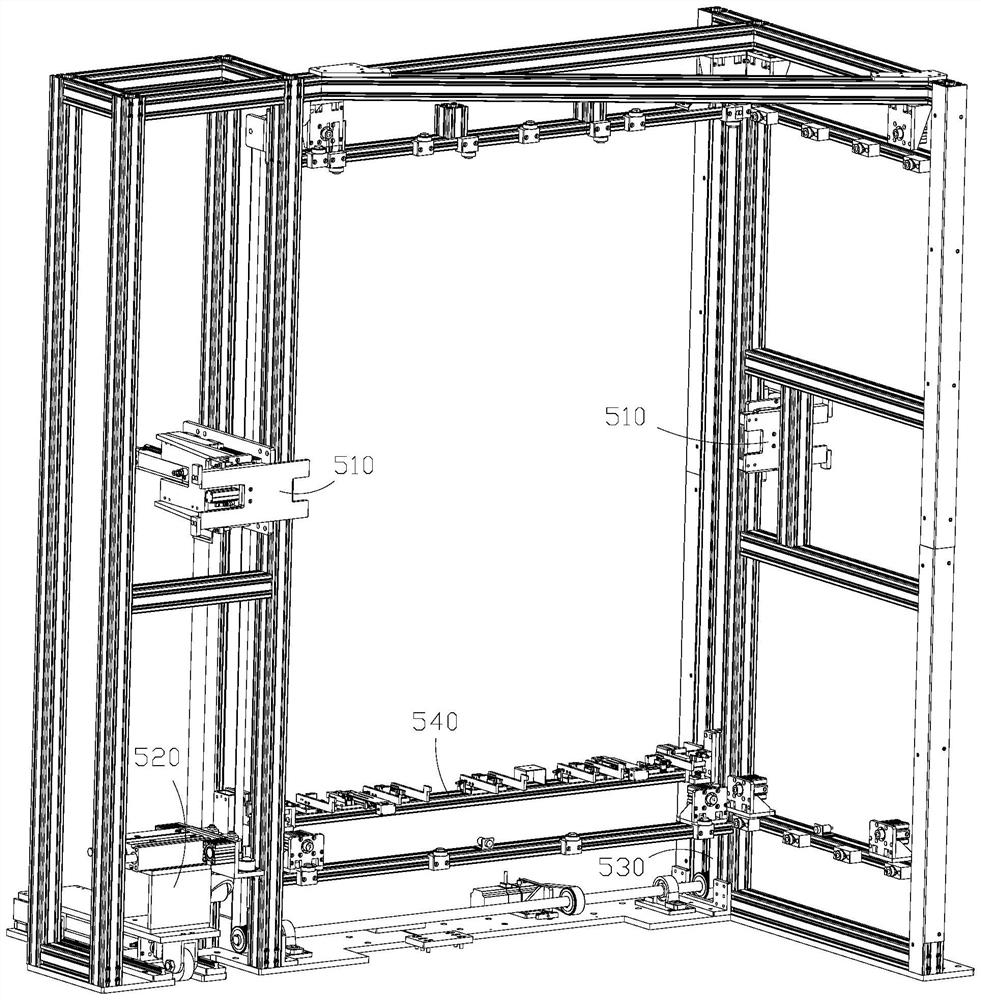

[0038] Such as figure 2 , 3 As shown, the inner and outer sides of the long side of the L-shaped positioning bracket 500 are respectively provided with a front pressing mechanism 510, which is located in the middle of the height direction, and is used to press the trolley 300 tightly on the long side of the L-shaped positioning bracket 500.

[0039] Such as Figure 7 As shown, the front pressing mechanism 510 includes a mounting plate 511, a first sliding plate 512 and a second sliding plate 515; the mounting plate 511 is fixedly mounted on the L-shaped positioning bracket 500, and the first sliding plate 512 passes through the first linear guide rail 513 is installed on the mounting plate 511, and the first cylinder 514 is...

Embodiment 2

[0048] Such as Figure 9 and 10 , because there will be errors in the production of egg trolleys 300, even there will be errors between egg trolleys 300 of the same model, especially the assembly errors of egg trolley beams 320 and angle steel longitudinal beams 310. Therefore, in order for the robot 100 to accurately align when picking up the egg tray, it is necessary to add a ranging mechanism 540 and a guiding mechanism on the basis of the first embodiment to deal with assembly errors, measure errors in time, and adjust the trajectory of the robot 100.

[0049] Such as image 3 , 4 , 5 and 6, the ranging mechanism 540 includes a lifting mechanism 530 and a lifting beam 541, the lifting beam 541 is installed on the lifting mechanism 530, and the lifting beam 541 is parallel to the long side of the L-shaped positioning bracket 500 to realize lifting; The seventh cylinder 545 is installed on the lifting beam 541, and the distance measuring sensor 546 is installed on the sev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com