Copper wire tinning equipment capable of improving tinning efficiency

A copper wire tin plating and tin plating technology, applied in hot dip plating process, coating, metal material coating process and other directions, can solve problems such as affecting the tin plating efficiency of copper wire, difficult adhesion of tin liquid, etc., to improve the adhesion and firmness degree and stability, and the effect of improving the efficiency of tin plating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiment of the present application discloses a copper wire tinning equipment which improves tinning efficiency.

[0036] The following is attached Figure 1-5 The application is described in further detail.

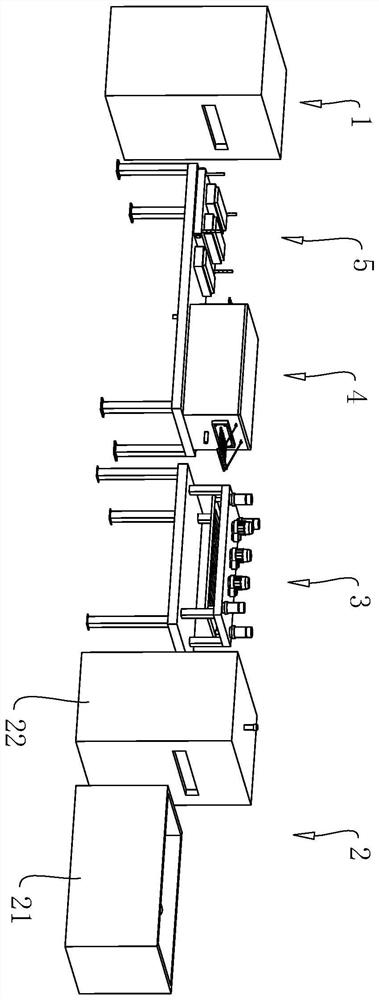

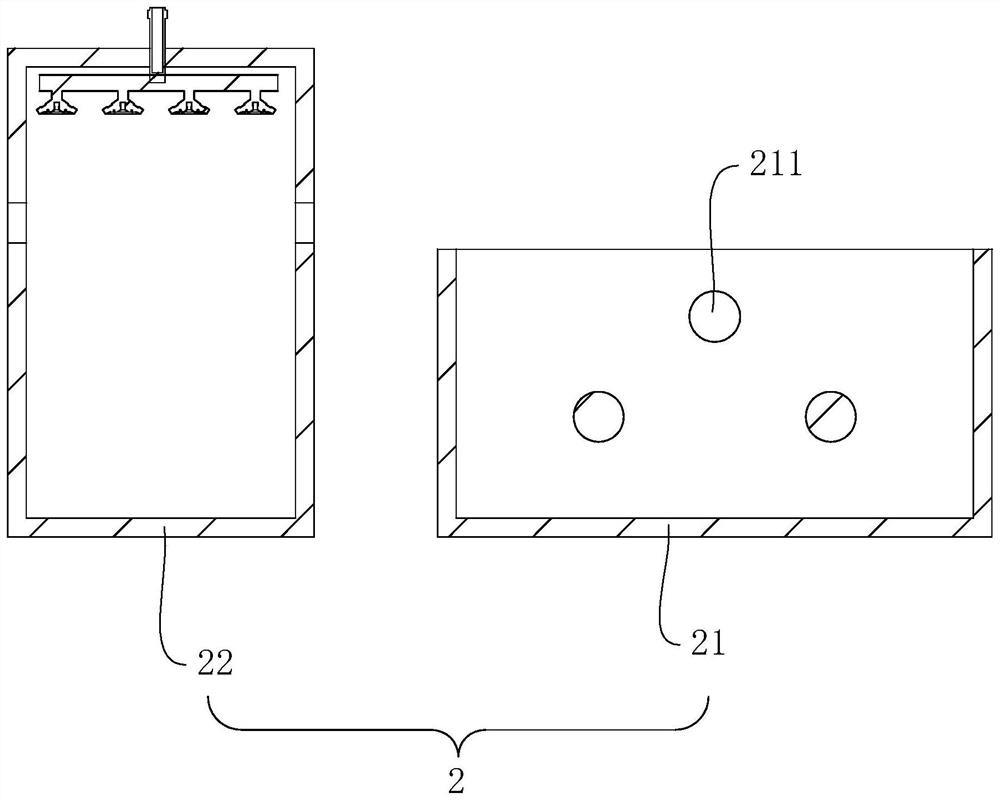

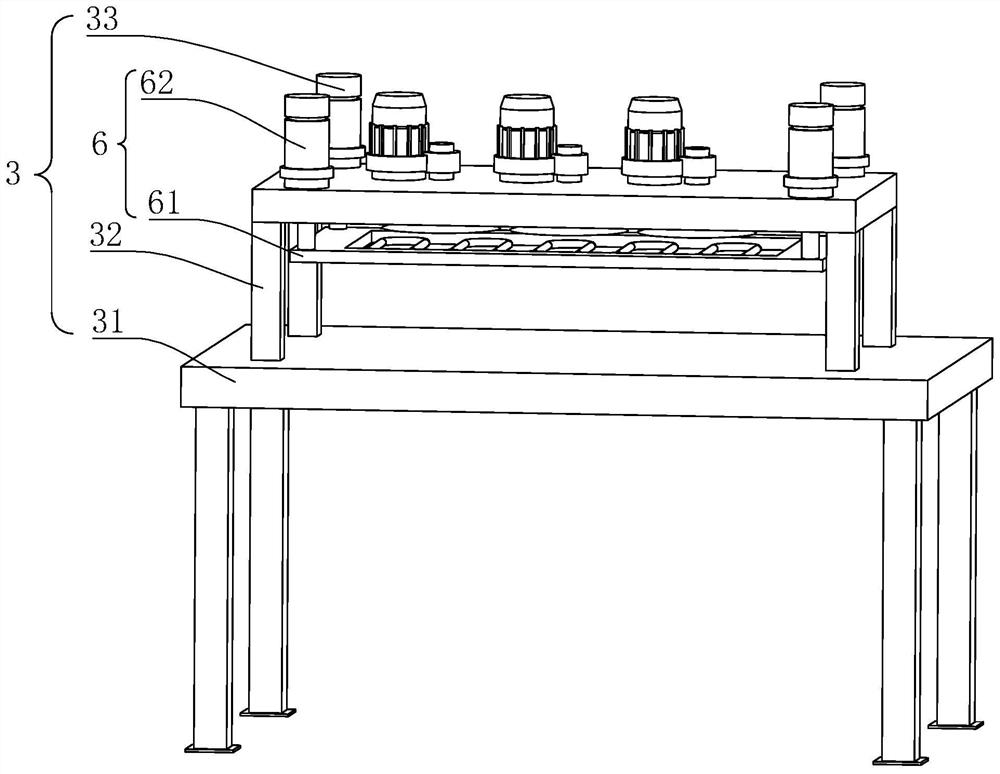

[0037] refer to figure 1 , the copper wire tinning equipment includes a tinning mechanism 1 . The operator makes the copper wire pass through the tinning mechanism 1 by pulling the equipment, and then the outer edge wall of the copper wire can be tinned. The tinning equipment for copper wires also includes a pickling mechanism 2 , a drying mechanism 3 , a softening mechanism 4 and a wiping mechanism 5 arranged in sequence, wherein the wiping mechanism 5 is arranged close to the tinning mechanism 1 . After the copper wire is pickled by the pickling mechanism 2, the stains on the outer edge wall are greatly reduced. Next, the drying mechanism 3 is used to remove water stains on the outer wall of the copper wire, the softening mechanism 4 softens the copper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com