Rapid pressure relief extraction method for short drill hole of fully mechanized coal mining face

A technology of fully mechanized mining face and working face, which is applied in drilling equipment and methods, drill pipes, drill pipes, etc., can solve the problems of gas control difficulties in mechanized mining face, and achieve increased recovery output, good practicability, and gas The effect of reducing the amount of gushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

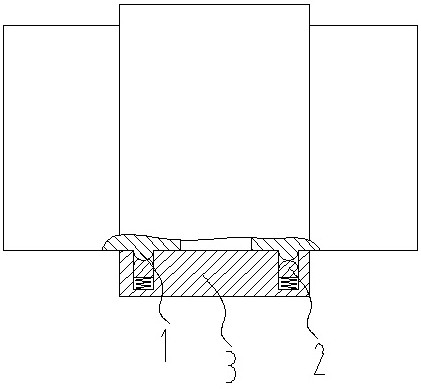

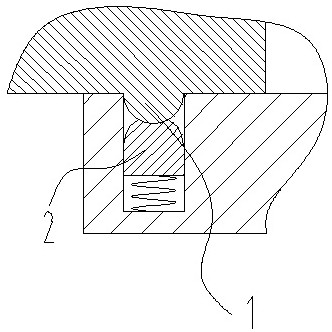

[0024] In order to make the technical means, creative features, goals and functions achieved by the present invention clearer and easier to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments:

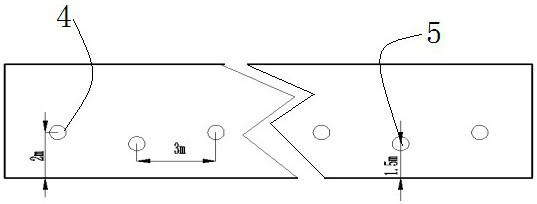

[0025] In order to explain the technical solution of the present invention, a specific construction scene is provided here. There is a specific working face, the fully mechanized mining face can adopt a strike length of 1400 meters, and an inclined length of 240m (0-900m advancing range) / 140m (900-1400m advancing range), this working face adopts full-height full-mechanized mining technology with one-time mining, and the whole caving method manages the roof. The west side of the 0-710m advance range of the working face is the 15116 goaf, and the west side of the 15116 working face within the 710-1400m advance range is not mined. The oblique structure of the working face is as follows: the overall shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com