Regenerated sealing oil composition and gas holder using same

A technology of composition and sealing oil, which is applied in the chemical industry, can solve problems such as uneven oil temperature in the oil ditch at the bottom of the cabinet, and achieve the effects of saving equipment investment and maintenance costs, increasing viscosity, and reducing gas emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

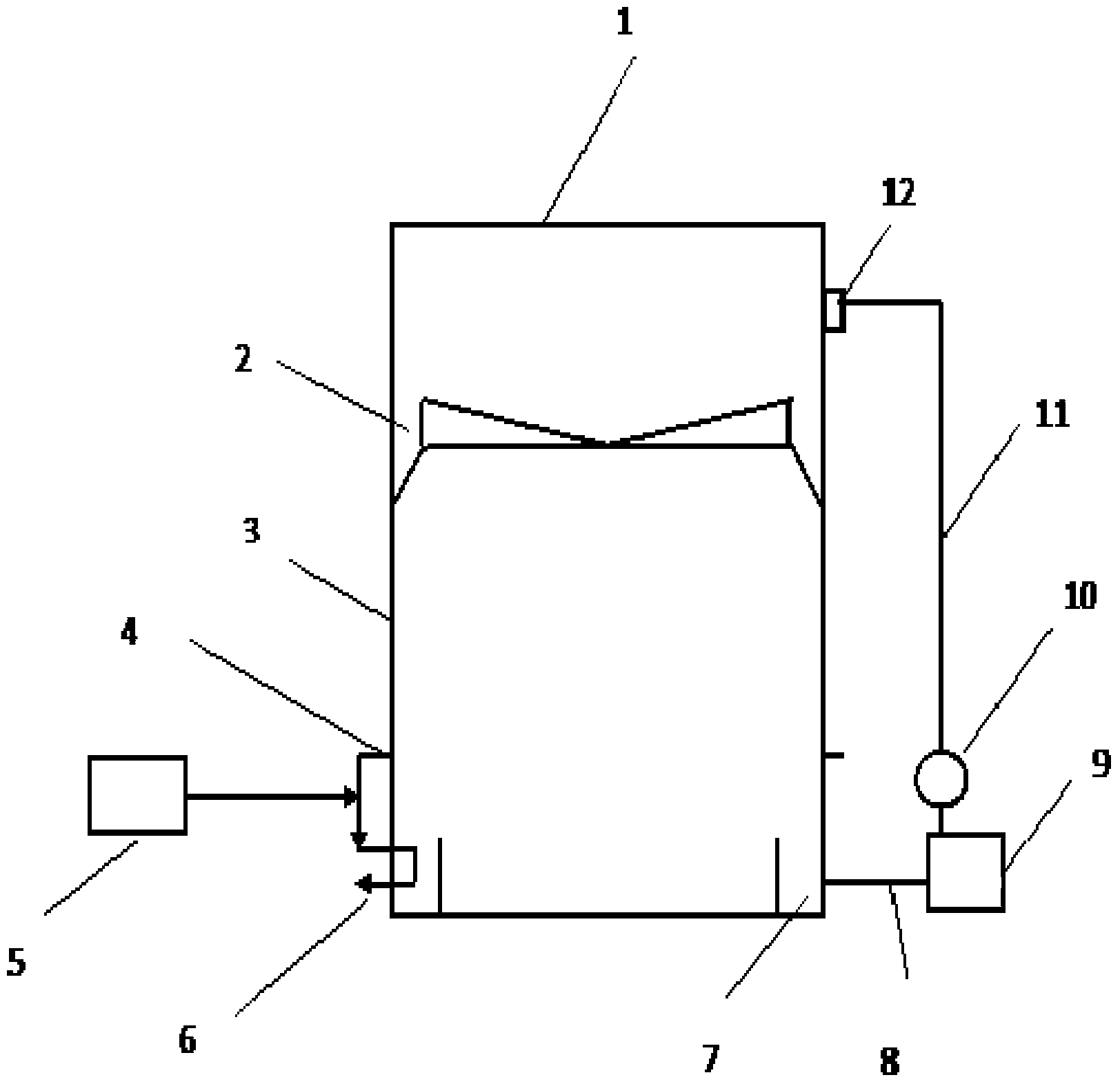

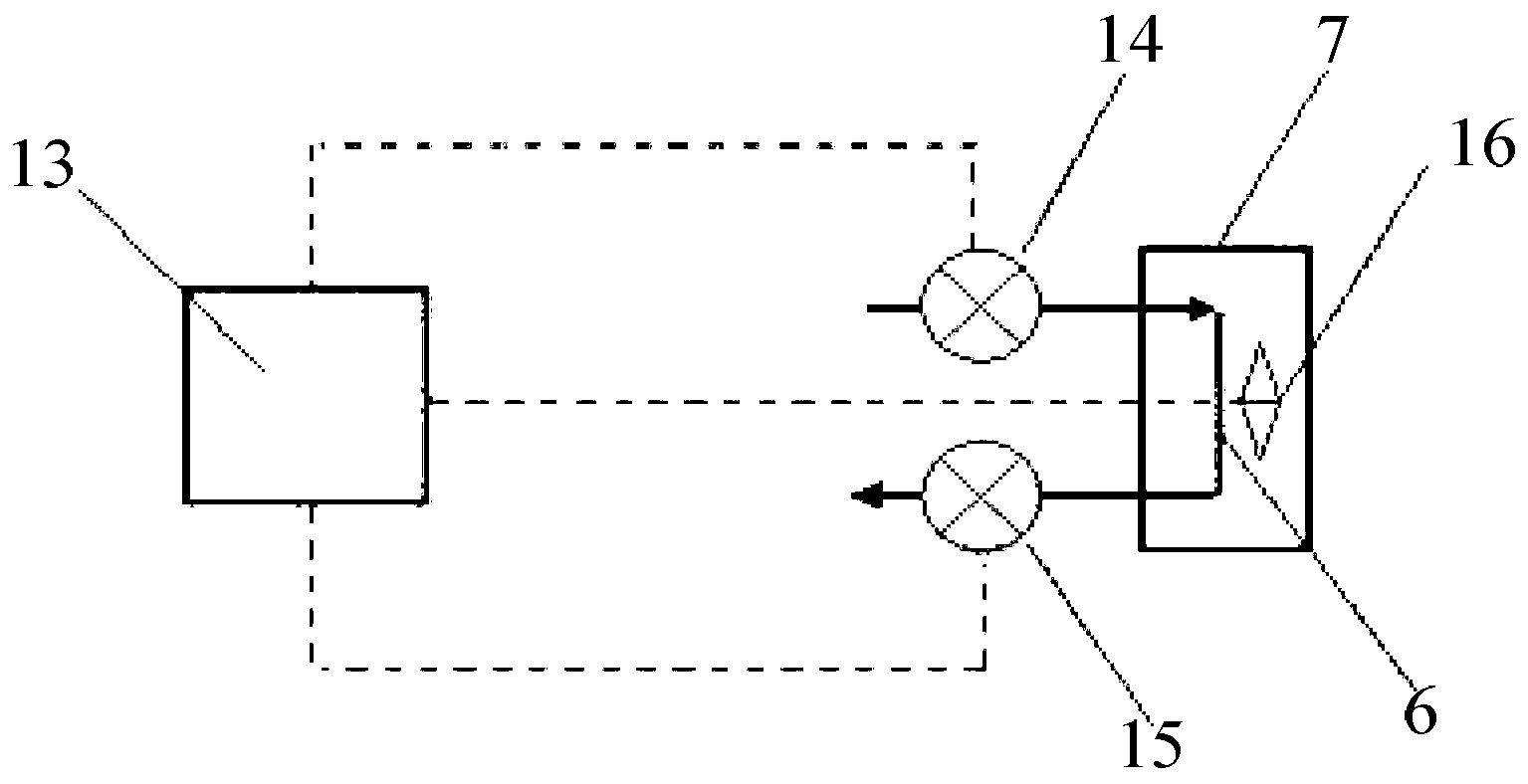

[0015] see figure 1 and figure 2 , the sealing oil regeneration composition provided by the embodiment of the present invention, comprising: an anti-emulsifier (ie, an amine and an epoxy compound) with a weight ratio of 3% to 5% (such as 3%, 4% or 5%), and a weight ratio of 5% to 10% (5%, 8% or 10%) of pour point depressant (i.e. polyalphaolefin), 5% to 12% (5%, 9% or 12%) of rust inhibitor by weight ( That is, dodecyl butyl diacid) and naphthenic base oil (viscosity 70-320) with a weight ratio of 73% to 87% (73%, 80% or 87%). The sealing oil regeneration composition accounts for 5%-10% (such as 5%, 8% or 10%) of the volume of the gas holder. The embodiment of the present invention also provides a gas cabinet for the application of the sealing oil regeneration composition, including: an oil-water separator 9, an oil pump 10, an overflow oil tank 12, a gas cabinet body 1, a piston oil tank 2, an oil groove 7, and a connecting pipe 8 , the upper oil pipe 11 and the heating u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com