A terminal structure of conduction cooling high temperature superconducting cable

A high-temperature superconducting and conduction cooling technology, which is applied to the cable accessories of low-temperature cables and the usage of superconductor elements, etc., can solve the problems of high cost, complex structure, inconvenient operation of supplementing and replacing liquid nitrogen, etc., and achieve low cost and high efficiency. Utilization efficiency, effect of reducing heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

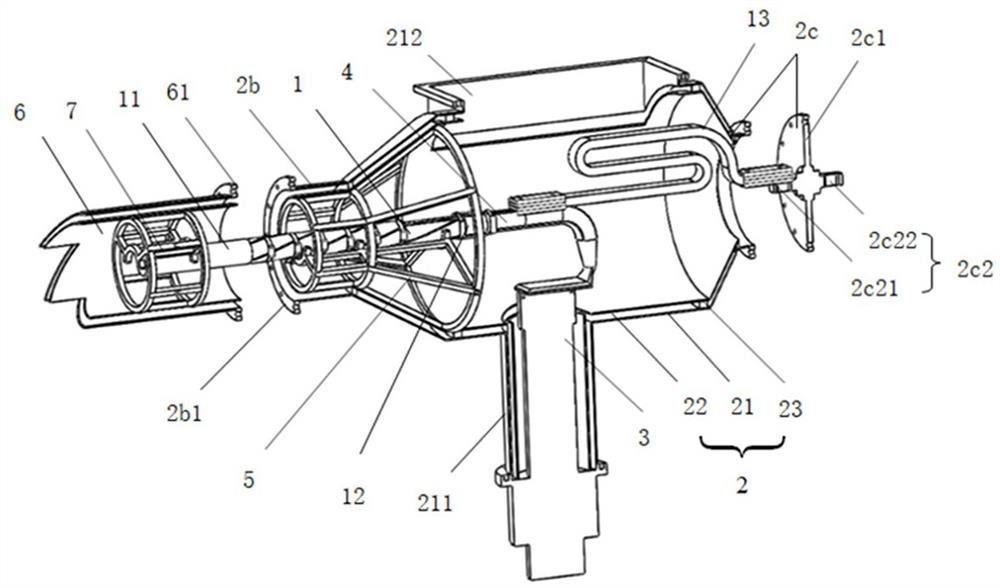

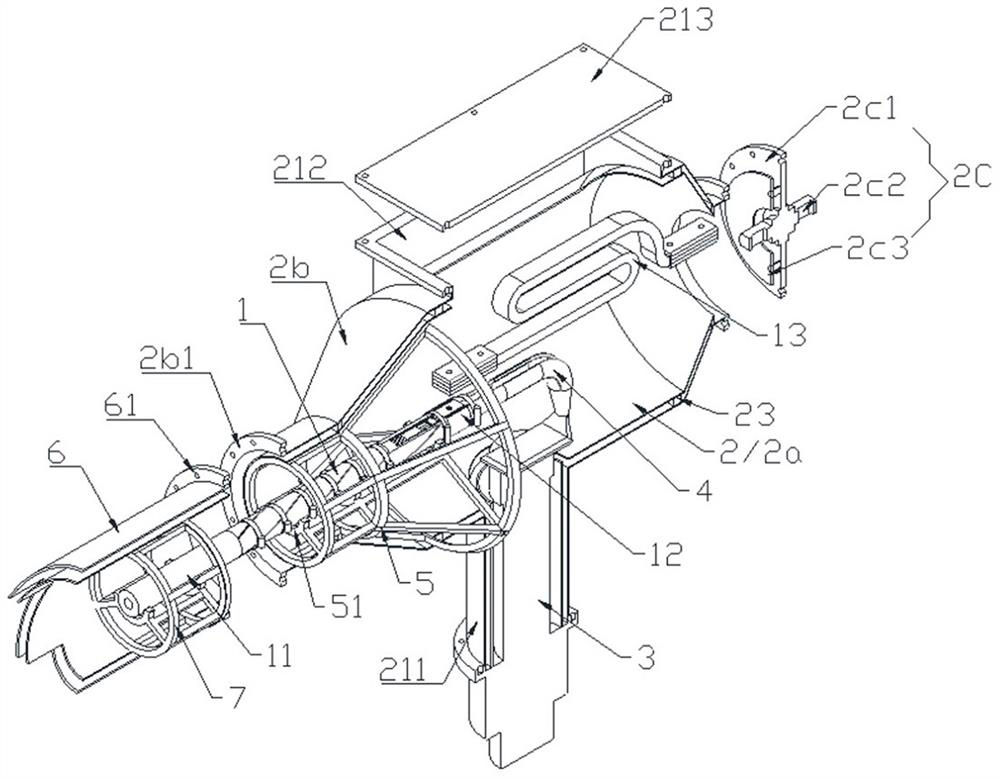

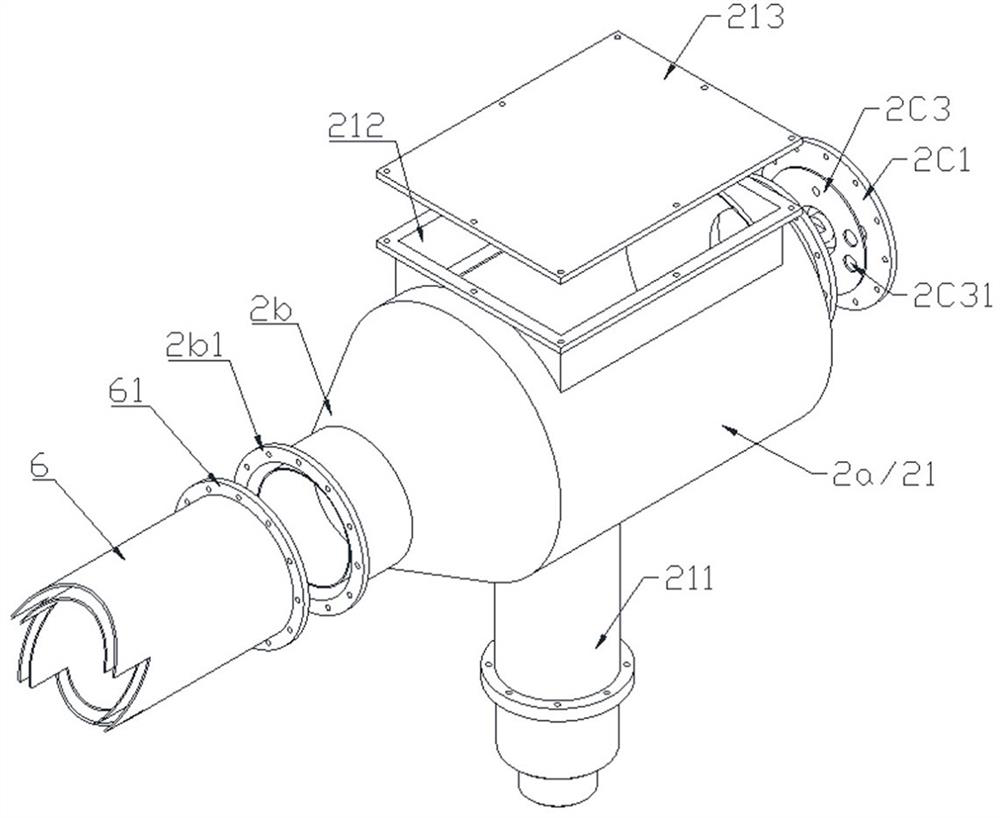

[0078] Such as Figure 1 to Figure 7 As shown, the embodiment of the present invention provides a terminal structure of a conduction cooling high temperature superconducting cable, which includes: a cable terminal body 1, a terminal heat insulation shell 2, and a refrigeration mechanism.

[0079] Specifically, a vacuum heat insulation cavity is formed in the terminal heat insulation shell 2, and the cable terminal main body 1 is arranged in the vacuum heat insulation cavity. The refrigerating mechanism includes a refrigerating output part, which protrudes into the vacuum insulation cavity, and the refrigerating output part is connected with the cable terminal main body 1 through a cooling structure 4 .

[0080] In this way, the cooling capacity generated by the refrigeration mechanism is output by the refrigeration output part, and then transferred to the cable terminal main body 1 through the cooling structure 4, so as to realize the cooling of the high-temperature supercondu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com