Three-dimensional multi-position inspection system for transformer substation

A patrol inspection system, a three-dimensional technology, applied in information technology support systems, circuits, collectors, etc., can solve problems such as heat generation, safety accidents, and hidden safety hazards left by batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

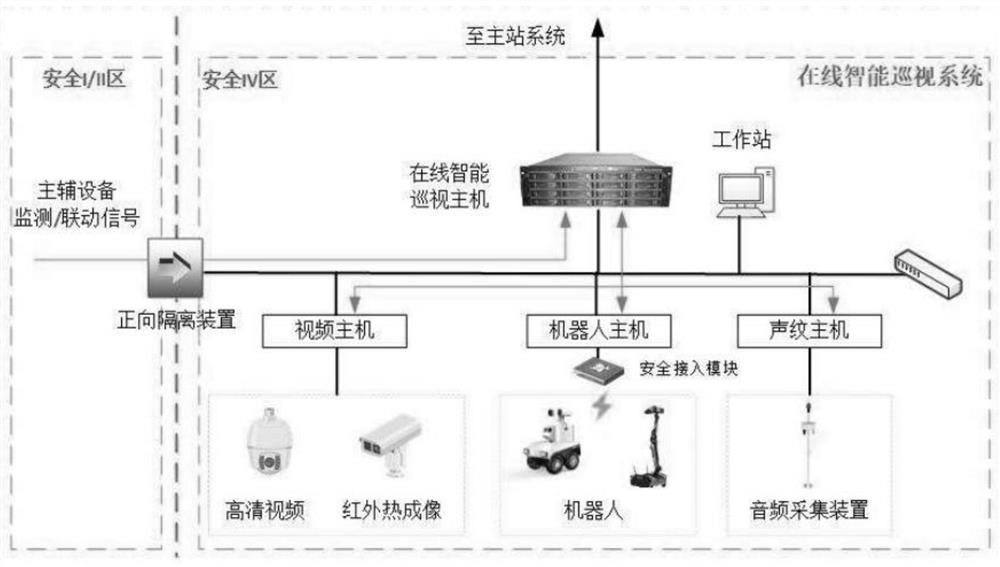

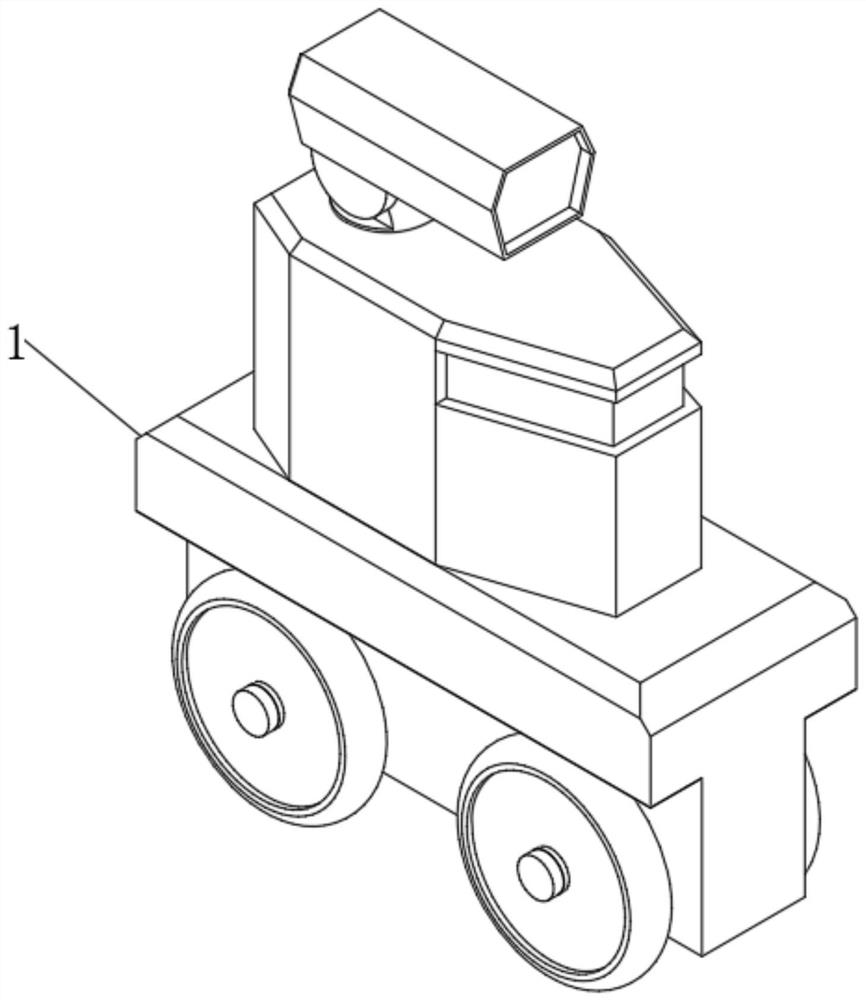

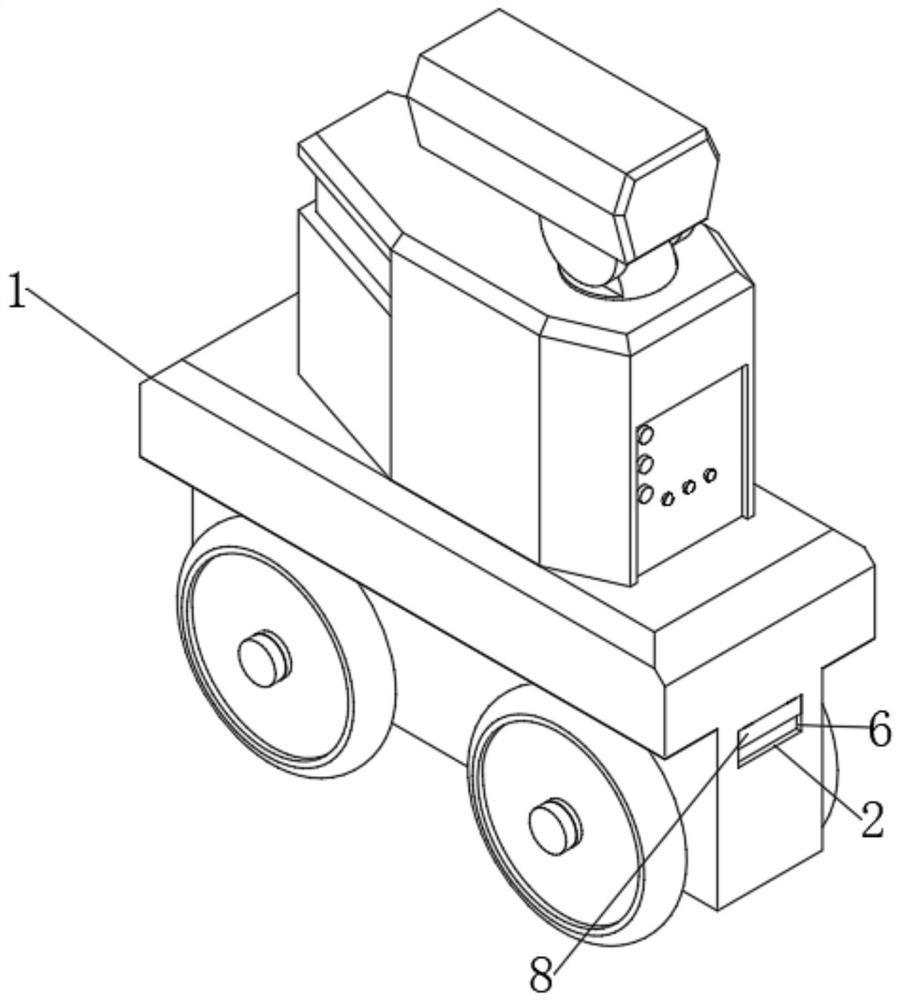

[0041] see figure 1 , a three-dimensional multi-position inspection system for substations, including an online intelligent inspection system. The online intelligent inspection system includes an online inspection host. The auxiliary equipment monitoring system obtains the monitoring data of the main equipment and auxiliary equipment through the positive isolation device. The main station system is used for the control of the substation and is connected with the substation control system of the upper level, the same level or the lower level for data exchange. The workstation is the display terminal of the online intelligent inspection host. The online intelligent inspection host is respectively connected to a video host, a robot host and a voiceprint host. The video host is connected to multiple high-definition video recording devices and infrared imaging devices. The robot host includes multiple An inspection robot, the voiceprint host includes multiple audio collection devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com