Improved cutter structure of air conditioner fin mold

An air-conditioning fin and improved technology, applied in the field of improved cutter structure, can solve the problems of easy sticking, no anti-sticking layer installed, waste, etc., and achieve the effect of preventing sticking and good use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

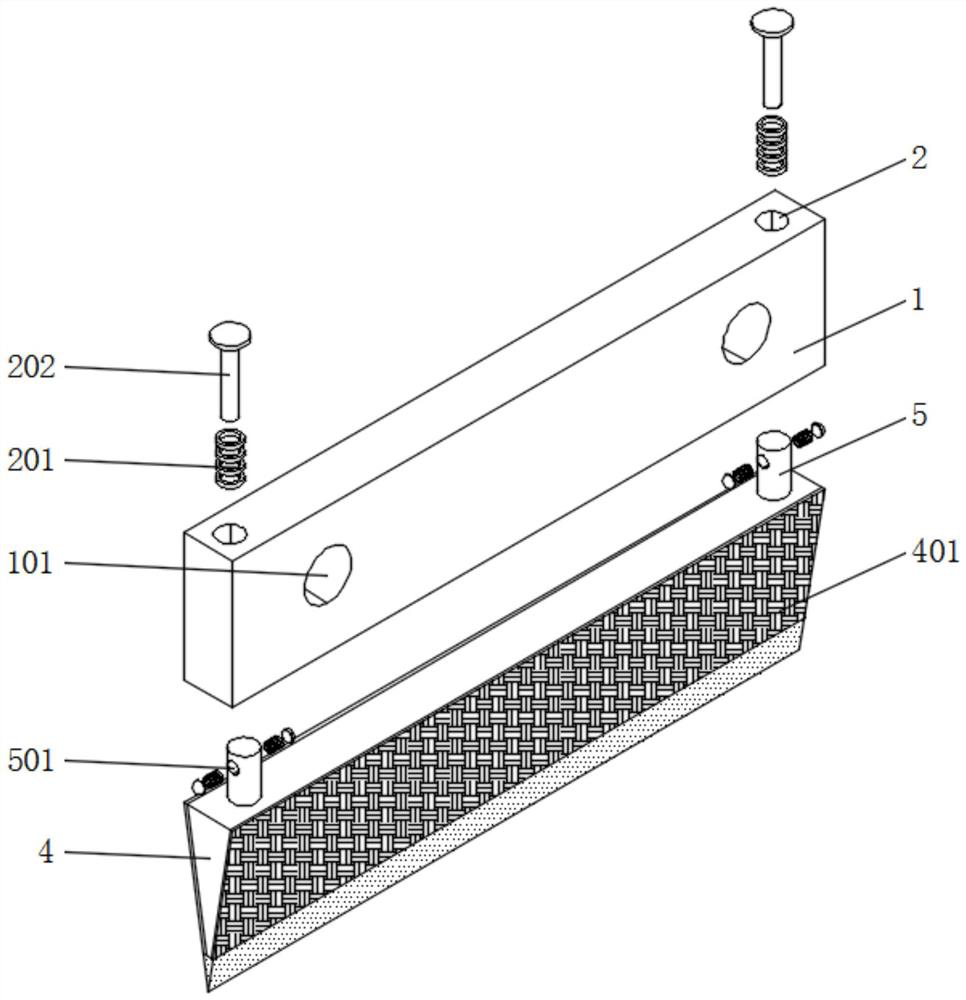

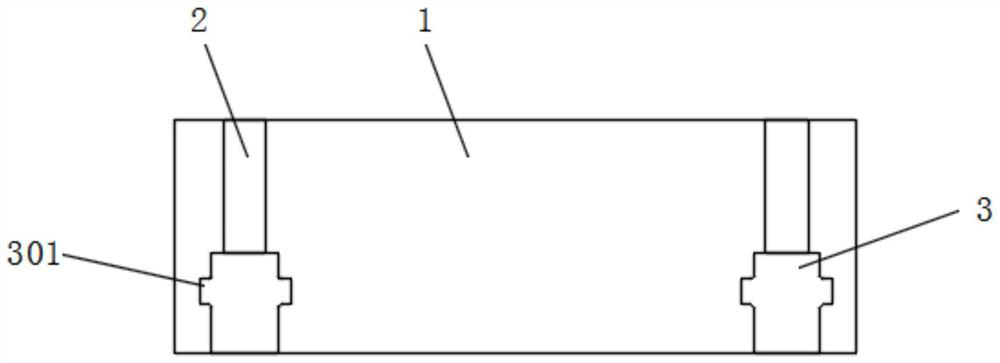

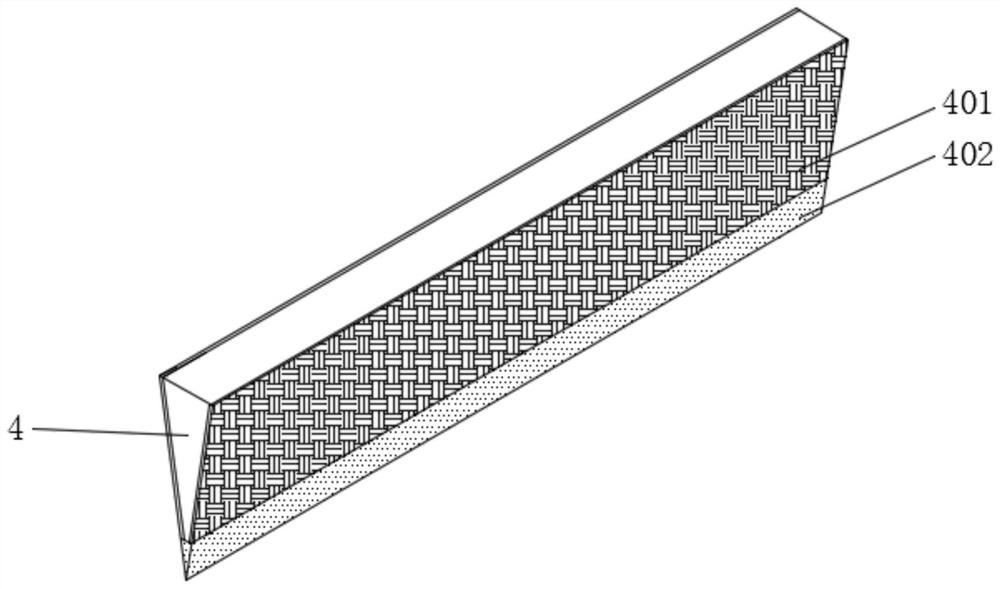

[0027] Embodiment 1, including a mounting plate 1, a mounting groove 2, a connecting groove 3 and a cutting blade 4, the top of the mounting plate 1 is symmetrically provided with a mounting groove 2, and the front of the mounting plate 1 is symmetrically opened with a fixing hole 101, and the mounting plate 1 starts To the effect of installation, the cutter can be installed through the installation plate 1, and also provide space for the opening of the fixing hole 101. The fixing hole 101 plays a role of fixing, providing space for the fixing of the installation plate 1, and the installation groove 2 The first spring 201 is installed inside, and the top of the first spring 201 is equipped with a pressing rod 202, and the bottom end of the pressing rod 202 runs through the bottom of the installation groove 2, and the installation groove 2 provides an installation position for the installation of the first spring 201, so that it It can be installed. The top of the first spring 2...

Embodiment 2

[0029] The second embodiment includes a mounting column 5 , which is symmetrically installed on the top of the cutting blade 4 , and the mounting column 5 corresponds to the connecting groove 3 .

[0030] see Figure 4 , an embodiment provided by the present invention: an improved cutter structure of an air-conditioning fin mold;

Embodiment 3

[0031] Embodiment 3 includes installation holes 501, and the two sides of the installation column 5 are symmetrically provided with installation installation holes 501, and the two sides of the installation column 5 are installed with the second spring 502 through the installation holes 501, and one end of the second spring 502 is installed with a fixing button 503, and the fixed button 503 fits with the fixed groove 301, and the mounting column 5 corresponds to the connecting groove 3, providing a position for the opening of the mounting hole 501, and the mounting hole 501 is used to install the second spring 502, so that the second spring 502 can After installation, the second spring 502 makes the fixed button 503 movable after being squeezed, and then the fixed button 503 is fixed in the fixed groove 301 by the elastic potential energy generated by the extrusion, and the fixed button 503 enters the fixed groove 301, so that A cutting blade 4 can be installed.

[0032] Worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com